Woodworker's Journal 1984-8-5, страница 21

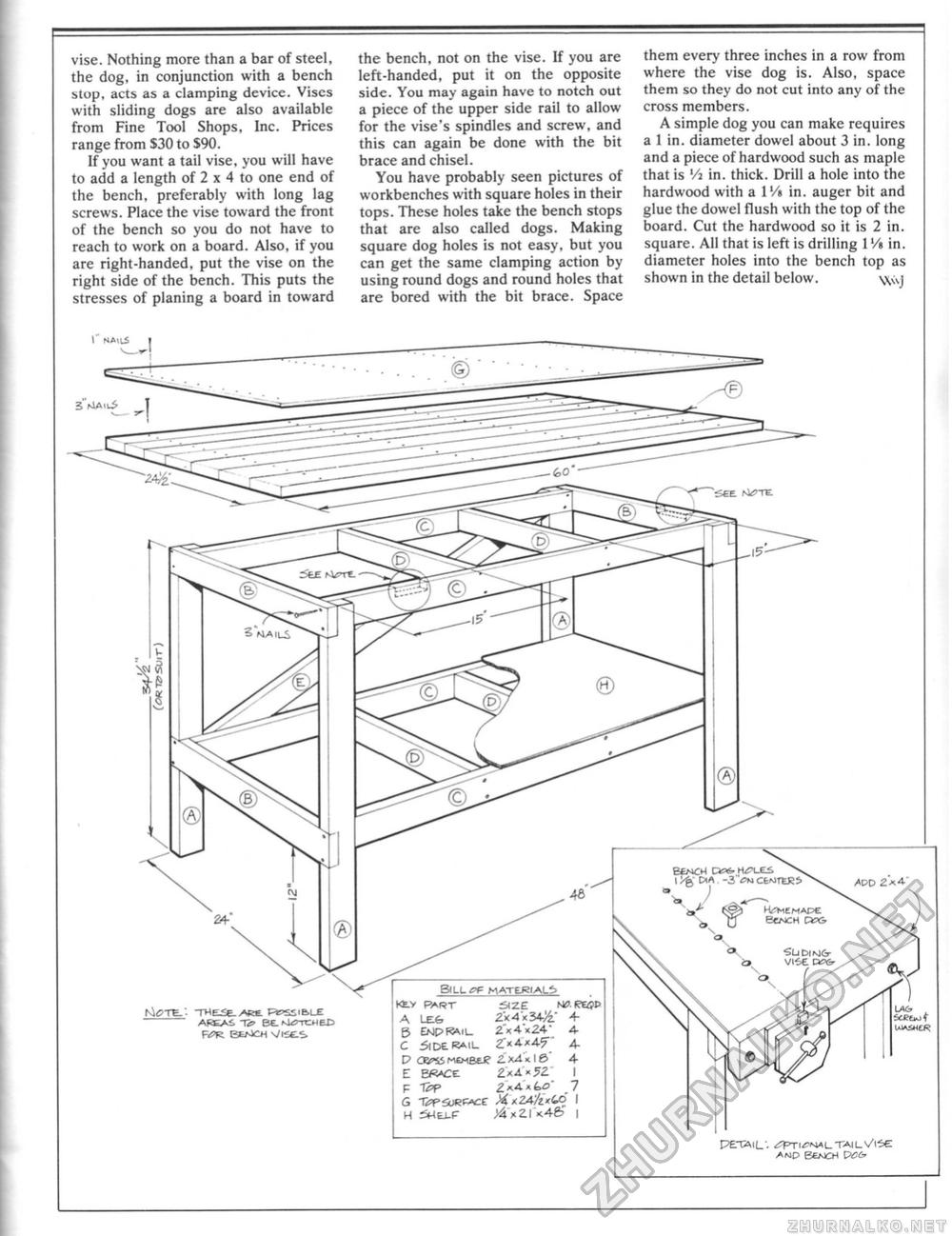

vise. Nothing more than a bar of steel, the dog, in conjunction with a bench stop, acts as a clamping device. Vises with sliding dogs are also available from Fine Tool Shops, Inc. Prices range from S30 to $90. If you want a tail vise, you will have to add a length of 2 x 4 to one end of the bench, preferably with long lag screws. Place the vise toward the front of the bench so you do not have to reach to work on a board. Also, if you are right-handed, put the vise on the right side of the bench. This puts the stresses of planing a board in toward the bench, not on the vise. If you are left-handed, put it on the opposite side. You may again have to notch out a piece of the upper side rail to allow for the vise's spindles and screw, and this can again be done with the bit brace and chisel. You have probably seen pictures of workbenches with square holes in their tops. These holes take the bench stops that are also called dogs. Making square dog holes is not easy, but you can get the same clamping action by using round dogs and round holes that are bored with the bit brace. Space them every three inches in a row from where the vise dog is. Also, space them so they do not cut into any of the cross members. A simple dog you can make requires a I in. diameter dowel about 3 in. long and a piece of hardwood such as maple that is Vj in. thick. Drill a hole into the hardwood with a IV» in. auger bit and glue the dowel flush with the top of the board. Cut the hardwood so it is 2 in. square. All that is left is drilling I Vt in. diameter holes into the bench top as shown in the detail below. \v\j P£T£<L". /PTI^^Ltail V16C amd beajch |