Woodworker's Journal 1984-8-6, страница 56

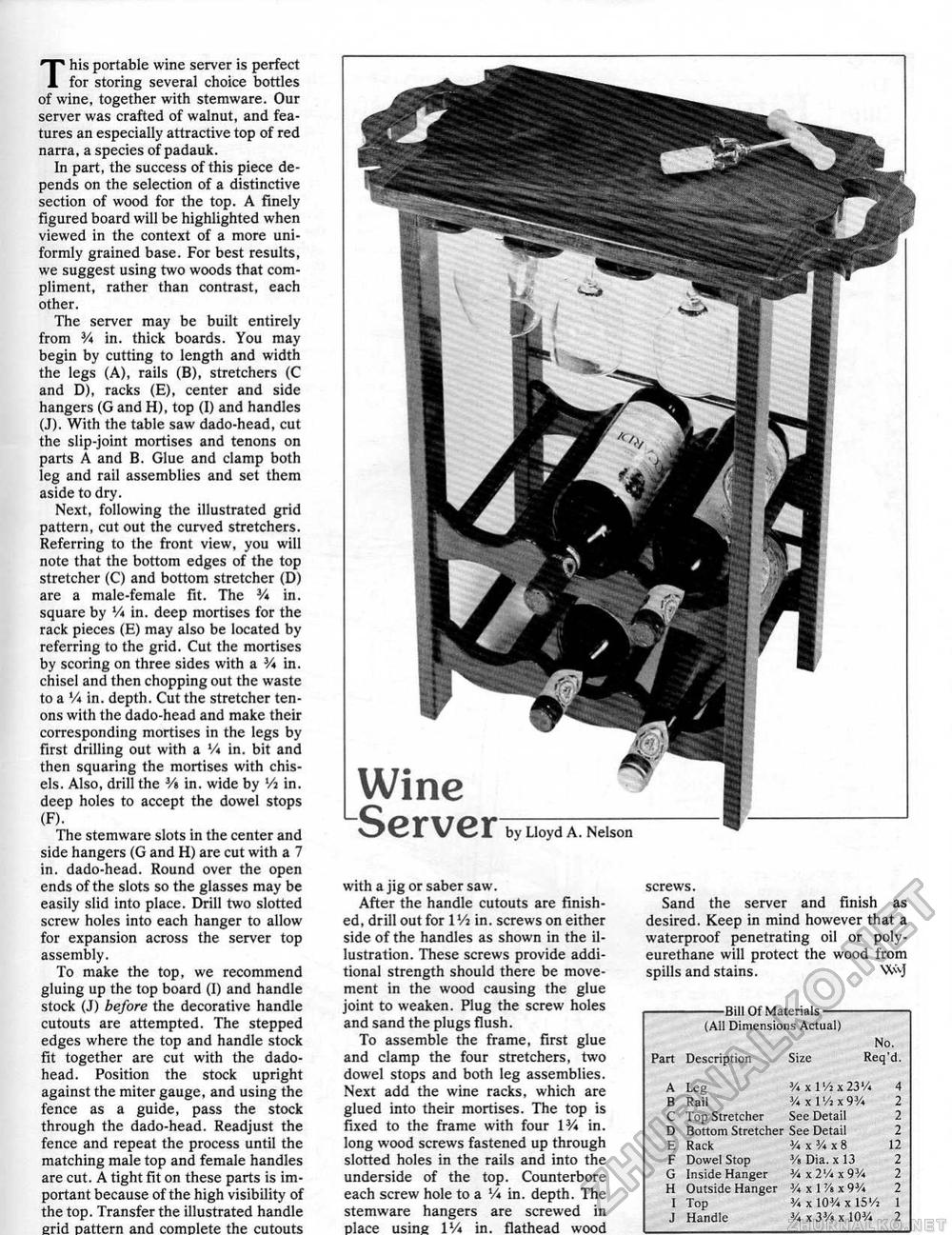

This portable wine server is perfect for storing several choice bottles of wine, together with stemware. Our server was crafted of walnut, and features an especially attractive top of red narra, a species of padauk. In part, the success of this piece depends on the selection of a distinctive section of wood for the top. A finely figured board will be highlighted when viewed in the context of a more uniformly grained base. For best results, we suggest using two woods that compliment, rather than contrast, each other. The server may be built entirely from V* in. thick boards. You may begin by cutting to length and width the legs (A), rails (B), stretchers (C and D), racks (E), center and side hangers (G and H), top (I) and handles (J). With the table saw dado-head, cut the slip-joint mortises and tenons on parts A and B. Glue and clamp both leg and rail assemblies and set them aside to dry. Next, following the illustrated grid pattern, cut out the curved stretchers. Referring to the front view, you will note that the bottom edges of the top stretcher (C) and bottom stretcher (D) are a male-female fit, The V* in. square by '/« in. deep mortises for the rack pieces (E) may also be located by referring to the grid. Cut the mortises by scoring on three sides with a V* in. chisel and then chopping out the waste to a V* in. depth. Cut the stretcher tenons with the dado-head and make their corresponding mortises in the legs by first drilling out with a Vt in. bit and then squaring the mortises with chisels. Also, drill the Vt in. wide by '/: in. deep holes to accept the dowel stops (F). The stemware slots in the center and side hangers (G and H) are cut with a 7 in. dado-head. Round over the open ends of the slots so the glasses may be easily slid into place. Drill two slotted screw holes into each hanger to allow for expansion across the server top assembly. To make the top, we recommend gluing up the top board (I) and handle stock (J) before the decorative handle cutouts are attempted. The stepped edges where the top and handle stock fit together are cut with the dado-head. Position the stock upright against the miter gauge, and using the fence as a guide, pass the stock through the dado-head. Readjust the fence and repeat the process until the matching male top and female handles are cut. A tight fit on these parts is important because of the high visibility of the top. Transfer the illustrated handle erid pattern and complete the cutouts with a jig or saber saw. After the handle cutouts are finished, drill out for 1 Vi in. screws on either side of the handles as shown in the illustration. These screws provide additional strength should there be movement in the wood causing the glue joint to weaken, Plug the screw holes and sand the plugs flush. To assemble the frame, first glue and clamp the four stretchers, two dowel stops and both leg assemblies. Next add the wine racks, which are glued into their mortises. The top is fixed to the frame with four 1V* in. long wood screws fastened up through slotted holes in the rails and into the underside of the top. Counterbore each screw hole to a V* in. depth. The stemware hangers are screwed in place using IV* in. flathead wood screws. Sand the server and finish as desired. Keep in mind however that a waterproof penetrating oil or poly-eurethane will protect the wood from spills and stains. Wvj -Bill Of Materials- (All Dimensions Actual) No. -Bill Of Materials- (All Dimensions Actual) No.

|