Woodworker's Journal 1985-9-1, страница 49

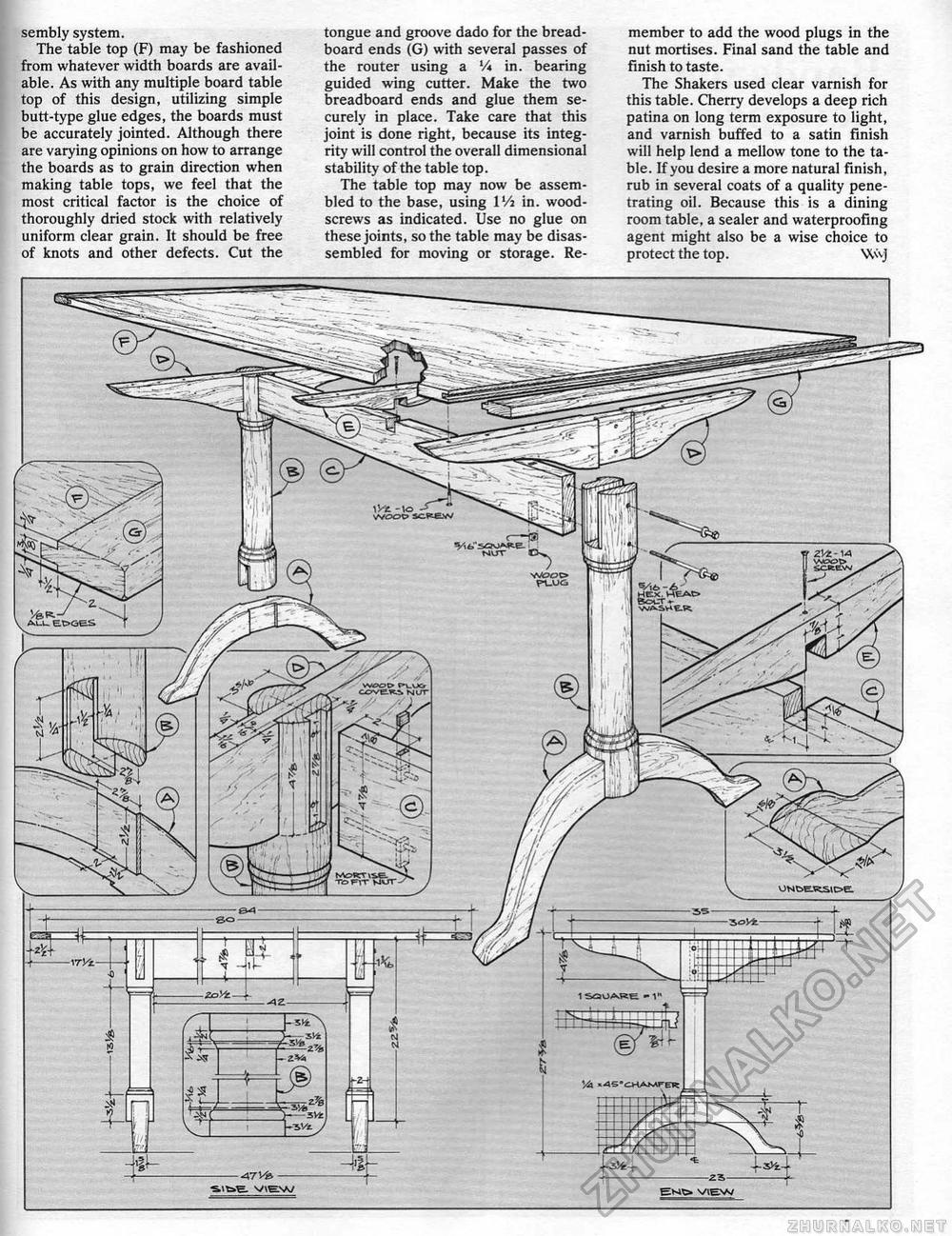

sembly system. The table top (F) may be fashioned from whatever width boards are available. As with any multiple board table top of this design, utilizing simple butt-type glue edges, the boards must be accurately jointed. Although there are varying opinions on how to arrange the boards as to grain direction when making table tops, we feel that the most critical factor is the choice of thoroughly dried stock with relatively uniform clear grain. It should be free of knots and other defects. Cut the tongue and groove dado for the breadboard ends (G) with several passes of the router using a Vi in. bearing guided wing cutter. Make the two breadboard ends and glue them securely in place. Take care that this joint is done right, because its integrity will control the overall dimensional stability of the table top. The table top may now be assembled to the base, using l'/i in. wood-screws as indicated. Use no glue on these joints, so the table may be disassembled for moving or storage. Re member to add the wood plugs in the nut mortises. Final sand the table and finish to taste. The Shakers used clear varnish for this table. Cherry develops a deep rich patina on long term exposure to light, and varnish buffed to a satin finish will help lend a mellow tone to the table. If you desire a more natural finish, rub in several coats of a quality penetrating oil. Because this is a dining room table, a sealer and waterproofing agent might also be a wise choice to protect thetop. Wwj CC»E*4NUT - EMti VIEW |