Woodworker's Journal 1985-9-5, страница 45

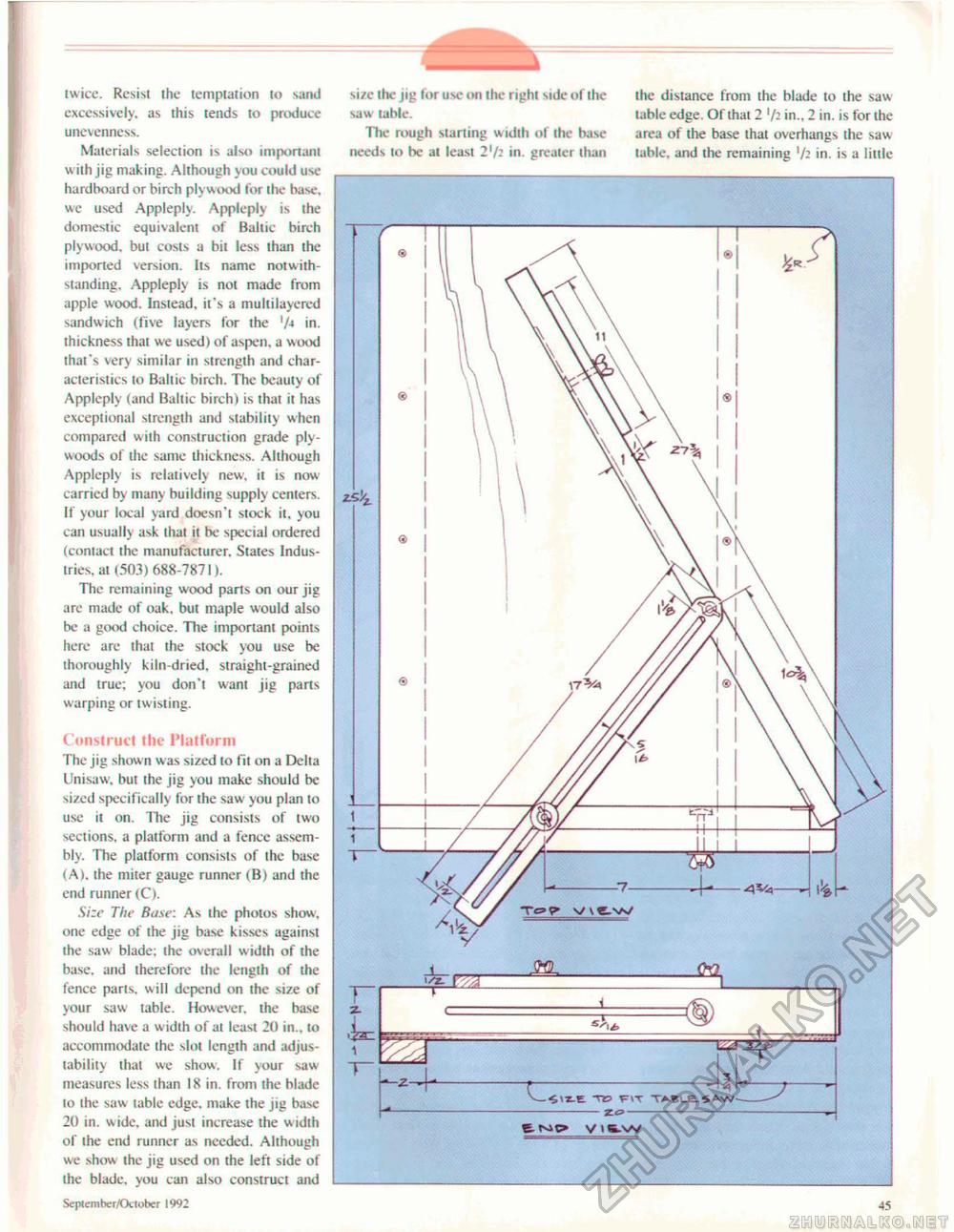

twice. Resist the temptation to sand excessively, as this tends to produce unevenness. Materials selection is also important with jig making. Although you could use hard board or birch plywood Tor (he base, we used Appleply. Appleply is the domestic equivalent of Baltic birch plywood, but costs a bit less than (he imported version. Its name notwithstanding. Appleply is not made from apple wood. Instead, it's a multilayered sandwich (five layers for the ■/-« in. thickness that we used) of aspen, a wood that's very similar in strength and characteristics to Baltic birch. The beauty of Appleply (and Baltic birch) is that it has exceptional strength and stability when compared with construction grade plywoods of the same thickness. Although Appleply is relatively new, it is now carried by many building supply centers, if your local yard doesn't stock it. you can usually ask thai it be special ordered (contact the manufacturer. Stales Industries, at (503) 688-7871). The remaining wood parts on our jig are made of oak. but maple would also be a good choice. The important points here are that the stock you use be thoroughly kiln-dried, straight-grained and true: you don't want jig parts warping or twisting. Construct the Platform The jig shown was sized to fit on a Delta Unisaw. bul (he jig you make should be sized specifically for the saw you plan lo use it on. The jig consists of two sections, a platform and a fence assembly. The platform consisls of the base (A), the miter gauge runner (B) and the end runner (C). Size The Base: As the photos show, one edge of the jig base kisses against the saw blade; the overall widlh of the base, and therefore the length of the fence parts, will depend on the size of your saw table. However, the base should have a w idth of at least 20 in., to accommodate the slot length and adjustability lhat we show. If your saw measures less than 18 in. from the blade lo the saw table edge, make the jig base 20 in. wide, and just increase the width of the end runner as needed, Although we show the jig used on the left side of the blade, you can also construct and September/October 1992 45 size the jig for use on the right side of the saw table. The rough starling width of the base needs lo be ai least l'/2 in. greater than the distance from the blade to the saw table edge. Of lhat 2 in., 2 in. is for the area of the base thai overhangs the saw table, and the remaining in. is a little |