Woodworker's Journal 1993-17-3, страница 34

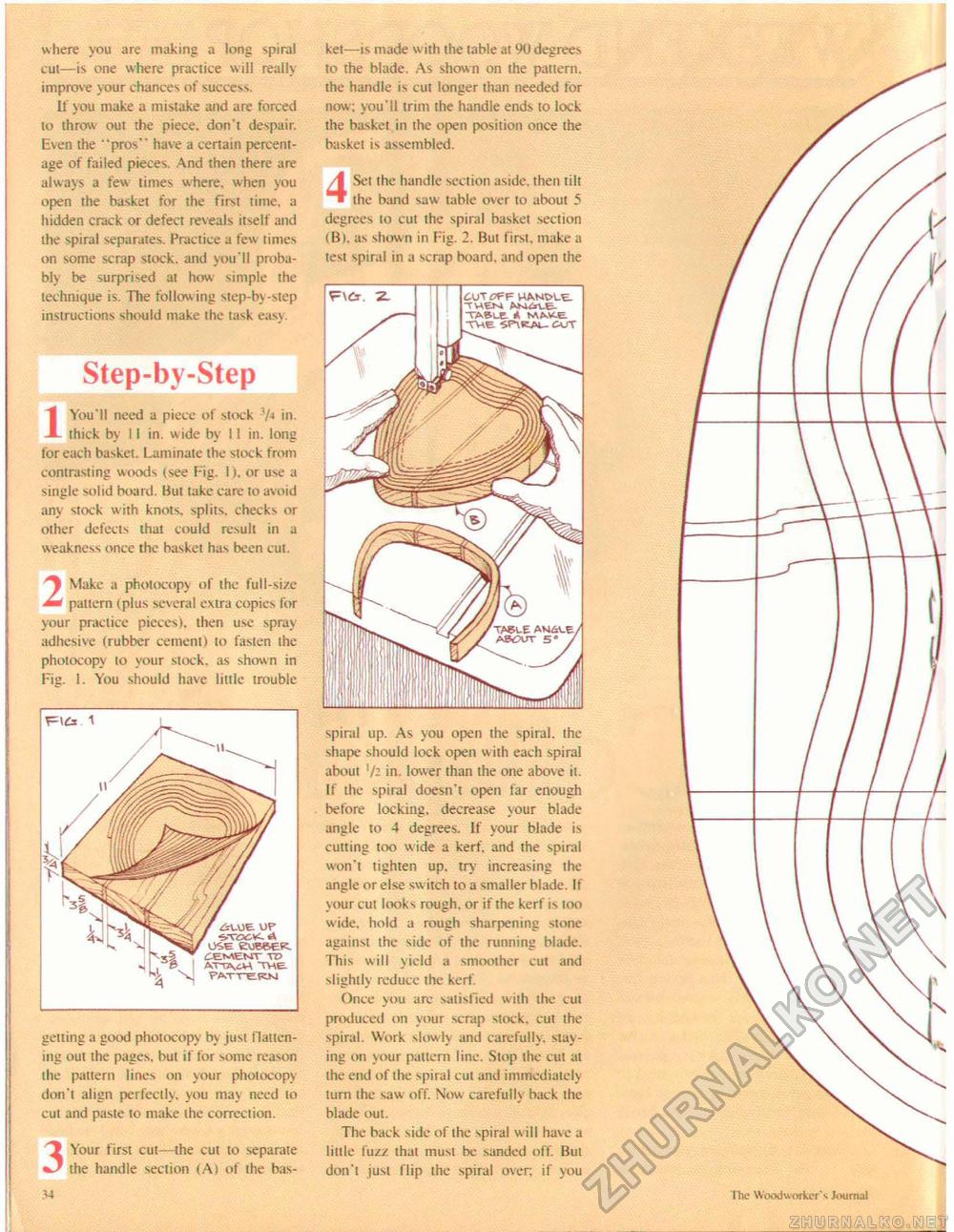

where you are making a long spiral cut—is one where practice will really improve your chances of success. if you make a mistake and are forced to throw out the piece, don't despair. Even the "pros" have a certain percentage of failed pieces, And then there are always a few limes where, when you open the basket for the first time, a hidden crack or defect reveals itself and the spiral separates. Practice a few times on some scrap stock, and you'll probably be surprised at how simple the technique is. The follow ing step-by-step instructions should make ihe task easy. Step-by-Step 1 You'll need a piece of stock ■'/■» in-thick by 11 in. w ide by 11 in. long for each basket. Laminate the stock from contrasting woods (see Fig. 1), or use a single solid board. But take care to avoid any stock w ith knots, splits, checks or other defects that could result in a weakness once the basket has been cut. 2 Make a photocopy of ihe full-size pattern (plus several extra copies for your practice pieces), then use spray adhesive (rubber cement) to fasten the photocopy to your slock, as shown in Fig. 1. You should have little trouble getting a good photocopy by jusl flattening out the pages, but if for some reason the pattern lines on your photocopy don't align perfectly, you may need lo cut and paste to make the correction. 3 Your first cut—the cut to separate the handle section (A) of the bas ket—is made w ith the table at 90 degrees to the blade. As shown on the pattern, the handle is cut longer than needed for now ; you'll trim the handle ends to lock the basket in the open position once the basket is assembled. 4 Set ihe handle section aside, then tilt (he band saw table over to about 5 degrees (o cut the spiral basket section (Bi. as shown in Fig. 2. But first, make a test spiral in a scrap board, and open the spiral up. As you open the spiral, the shape should lock open w ith each spiral about !/- in. lower than ihe one above it. If the spiral doesn't open far enough before locking, decrease your blade angle to 4 degrees. If your blade is cutting too wide a kerf, and the spiral won't tighten up. try increasing the angle or else switch to a smaller blade. It your cut Iwiks rough, or if the kerf is too wide, hold a rough sharpening stone against the side of the running blade. This will yield a smoother cut and slightly reduce the kerf. Once you are satisfied with the cut produced on your scrap siock. cut ihe spiral. Work slowly and carefully, staying on your pattern line. Stop ihe cut at the end of the spiral cut and immediately turn the saw off. Now carefullv back the blade oul. The back side of the spiral w ill have a little fuzz thai must be sanded off. But don't jusl flip the spiral oven if you 34 |