Woodworker's Journal 1993-17-3, страница 46

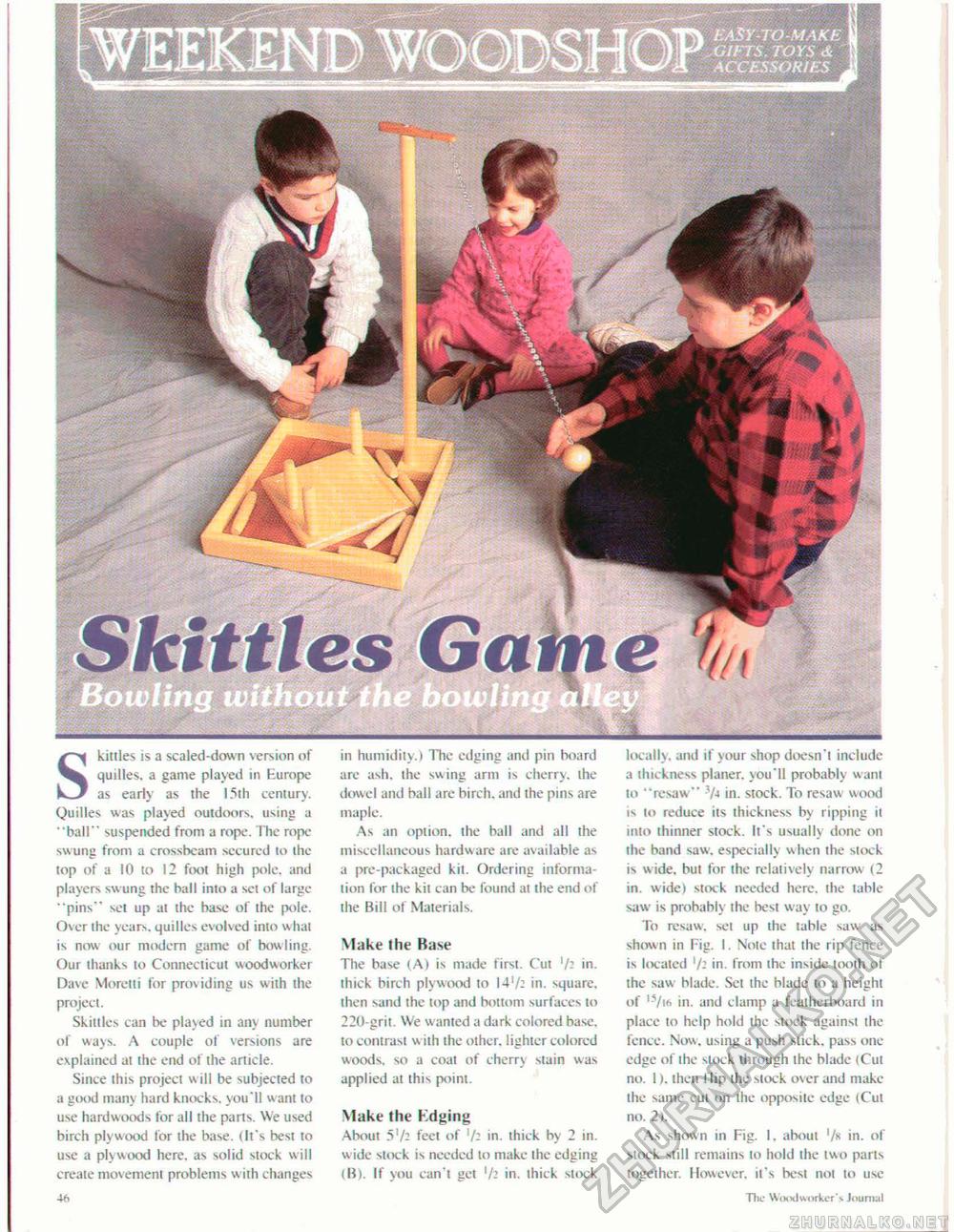

Skittles, is a scaled-down version of qutiles, a game played in Europe as early as the 15th century. Quilles was played outdoors, using a ' "ball" suspended from a rope. The rope swung from a crosshcam secured to the top of a 10 to 12 foot high pole, and players swung the ball into a set of large "pins" set up at the base of the pole. Over the years, quilles evolved into what is now our modern game of bowling. Our thanks lo Connecticut woodworker Dave Moretti for providing us w ith the project. Skittles can be played in any number of ways. A couple of versions are explained at the end of the article. Since this project w ill be subjected to a good many hard knocks, you'll want to use hardwoods for all the parts. We used birch plywood lor the base. (It's best to use a plywood here, as solid stock will create movement problems with changes 46 in humidity.) The edging and pin board are ash. the swing arm is cherry, the dowel and bail are birch, and the pins are maple. As an option, the ball and all the miscellaneous hardware are available as a pre-packaged kit. Ordering information lor the kit can be found at the end of the Bill of Materials. Make the Base The base (A) is made first. Cut '/- in. thick birch plywood to 14'/^ in. square, then sand the top and bottom surfaces to 220-grit. We wanted a dark colored base, to contrast with the other, lighter colored woods, so a coal of cherry stain was applied at this poini. Make the Edging About 57? feet of l/2 in. thick by 2 in. w idc stock is needed to make the edging (B). If you can't get 'h in. thick stock locally, and if your shop doesn't include a thickness planer, you'll probably want to "resaw" 7-t in. stock. To resaw wood is to reduce its thickness by ripping it into thinner stock. It's usually done on ihe band saw. especially when the stock is wide, but for the relatively narrow (2 in. wide) stock needed here, the lable saw is probably the best way to go. To resaw. set up the table saw as shown in Fig. I. Note that the rip fence is Unrated 7- in. from the inside tooth of the saw blade. Set the blade to a height of t3/ifi in. and clamp a feathcrboard in place to help hold the stock against the fence. Now. using a push stick, pass one edge of the slock through the blade (Cut no. I). then flip the stock over and make the same cut on the opposite edge (Cut no. 2). As shown in Fig. I. about 7« in. of stock still remains to hold the two parts together. However, it's besi not to use M The Woodworker's Journal |