Woodworker's Journal 1993-17-3, страница 47

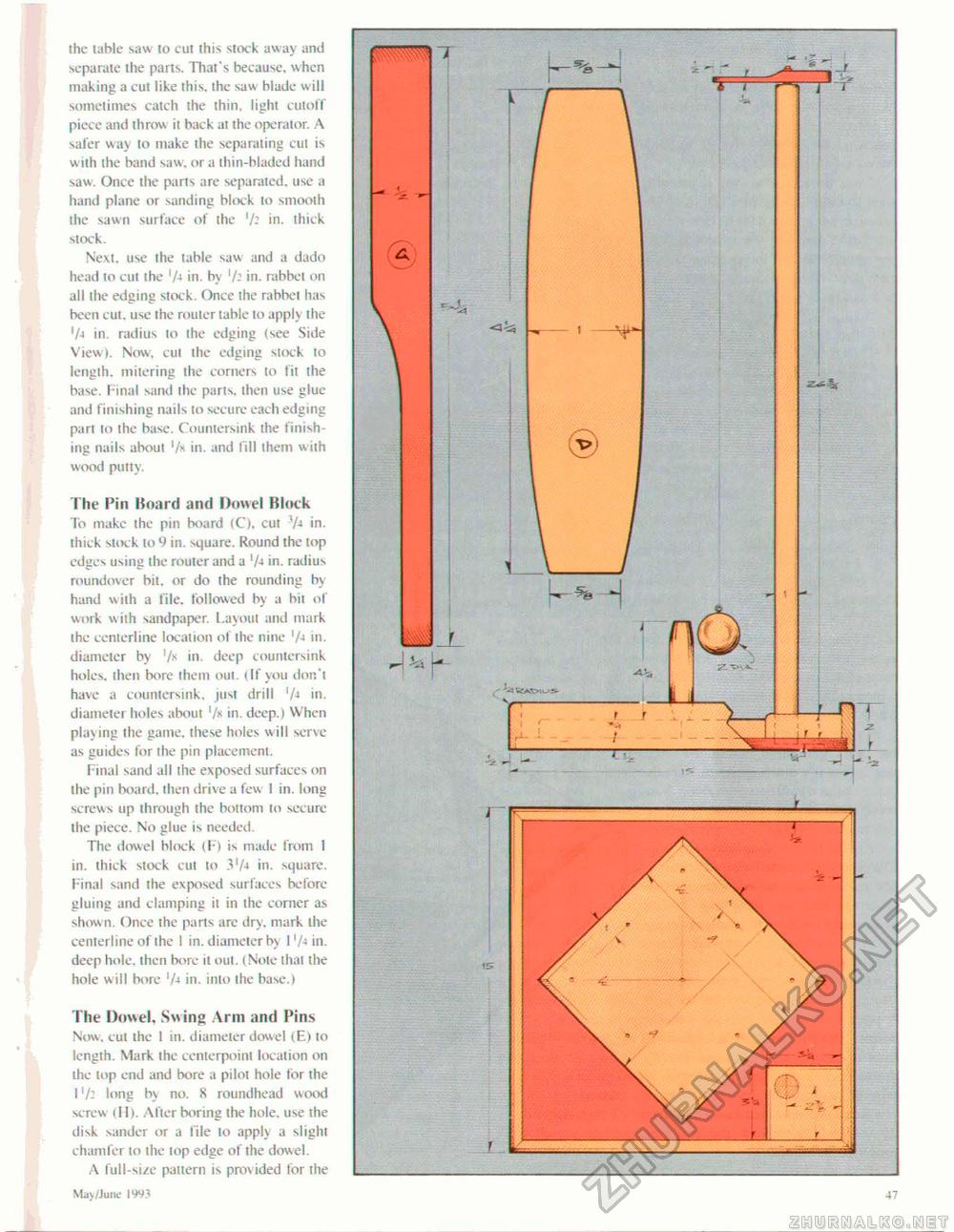

the table saw to cut this stock away and separate the parts. That's because, when making a cut like this, the saw blade will sometimes catch the thin, light cutoff piece and throw it back at the operator. A safer way to make the separating cut is with the band saw. or a thin-bladed hand saw. Once the parts are separated, use a hand plane or sanding block to smooth the sawn surface of the '/2 in. thick slock. Next, use the table saw and a dado head to cut the '/■» in. by '/- in. rabbet on all the edging stock. Once the rabbet has been cut, use the router table to apply the 1/j in. radius to the edging (see Side View). Now, cut the edging stock to length, mitering the corners to fit the base. Final sand the parts, then use glue and finishing nails to secure each edging part to the base. Countersink the finishing nails about '/* in. and fill them with wood putty. The Pin Board and Dowel Block To make the pin board (C), cut in. thick stock to 9 in. square. Round the top edges using the router and a '/-» in. radius roundover bit. or do the rounding by hand with a file, followed by a bit of work with sandpaper. Layout and murk the centerline location of the nine '/j in. diameter by in. deep countersink holes, then bore them out. (If you don't have a countersink, just drill 'A in. diameter holes about '/* in. deep.) When playing the game, these holes will serve as guides for the pin placement. Final sand all the exposed surfaces on the pin board, then drive a few I in. long screws up through the bottom to secure the piece. No glue is needed. The dowel block (F) is made Irom 1 in. thick stock cut to 37" in. square. Final sand the exposed surfaces before gluing and clamping it in the corner as shown. Once the parts are dry. mark the centerline of the I in. diameter by I 'A in-deep hole, then bore it out. (Note that the hole w ill bore 'A in. into the base.) The Dowel, Swing Arm and Pins Now, cut the I in. diameter dowel (E) to length. Mark the centerpoint location on the lop end and bore a pilot hole for the I1/: long by no. 8 roundhead wood screw (II)- After boring the hole, use the disk sander or a tile to apply a slight chamfer to the top edge of the dowel. A full-size pattern is provided for the May/June 1993

47 |

||||||||||||||||||||||||||||