Woodworker's Journal 1993-17-5, страница 48

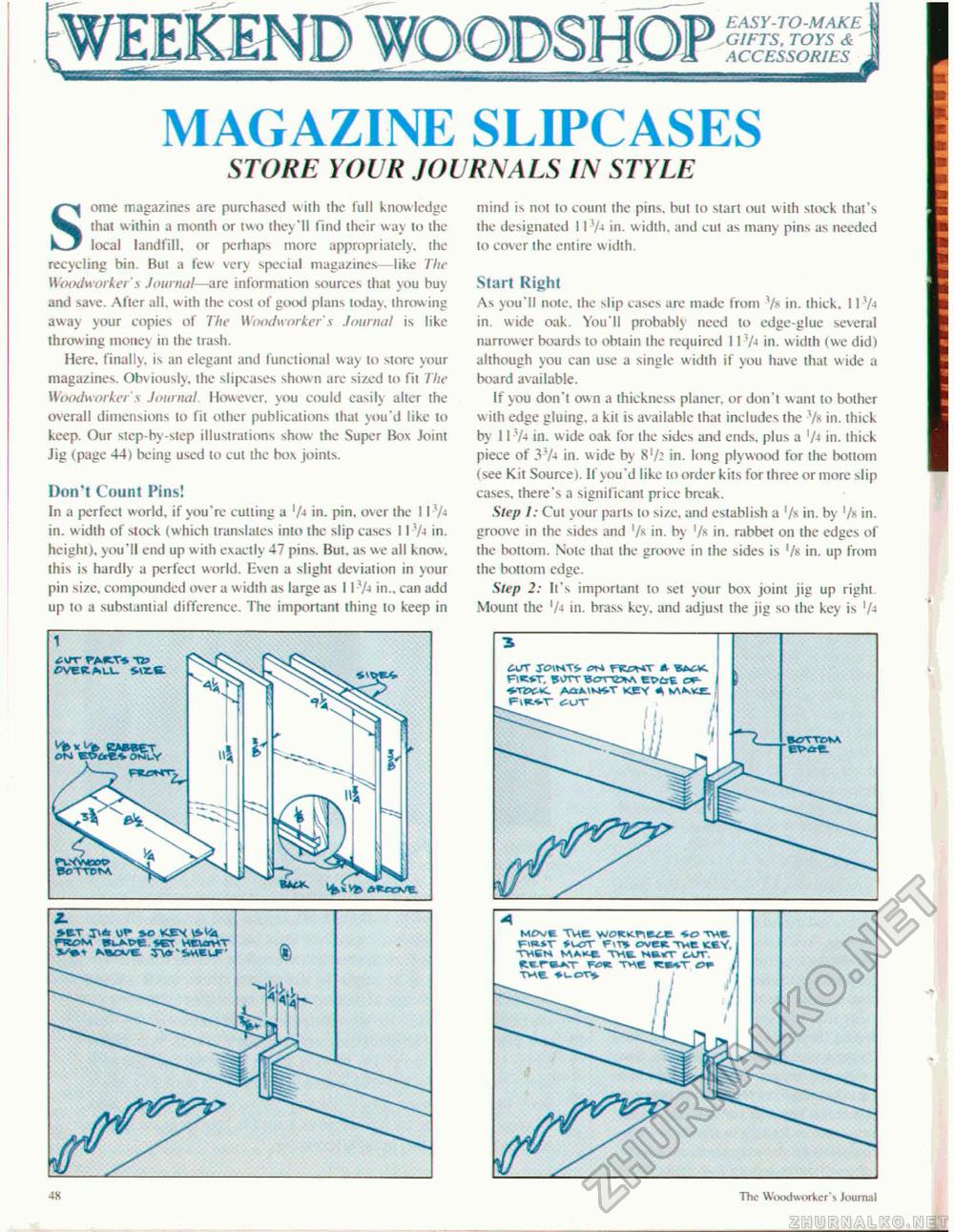

[WEEKEND WOODSHOP^Illf MAGAZINE SLIPCASESSTORE YOUR JOURNALS IN STYLE Some magazines are purchased with the full knowledge that within a month or two they'll find their way lo the local landfill, or perhaps more appropriately, the recycling bin. But a few very special magazines—like The Woodworker's Journal—are information sources that you buy and save. After all. with the cost of good plans today, throwing away your copies of The Woodworker's Journal is like throw ing money in the trash. Here, finally, is an elegant and functional way to store your magazines. Obviously, the siipeases shown are sized to lit The Woodworker's Journal However, you could easily alter the overall dimensions lo fit other publications that you'd like to keep. Our step-by-step illustrations show the Super Box Joint Jig (page 44) being used to cut the box joints. Don't Count Fins! In a perfect world, if you're cutting a 'A in. pin. over the I I-'A in. w idth of stock (which translates into the slip cases 11 -'A in. height). you'll end up with exactly 47 pins. But. as we all know, this is hardly a perfect world. Even a slight deviation in your pin size, compounded over a w idth as large as 11 *A in., can add up to a substantial difference. The important thing to keep in mind is not to count the pins, but to start out w ith stock that's the designated 11 '/•* in. w idth, and cut as many pins as needed to cover the entire width. Start Right As you'll note, the slip cases are made from V* in. thick, 11 *A in. wide oak. You'll probably need to edge-glue several narrower boards to obtain the required 113A in. width (we did) although you can use a single width if you have that wide a board available. If you don't own a thickness planer, or don't want to bother with edge gluing, a kit is available that includes the V« in. thick by 11 ?A in. w ide oak for the sides and ends, plus a 'A in. thick piece of 3'A in. wide by 8(A in. long plywood for the botiom (see Kit Source). If you'd like to order kits for three or more slip cases, there's a significant price break. Step /; Cut your parts to size, and establish a 'A in. by '/x in. groove in the sides and 'A in. by '/s in. rabbet on the edges of the bottom. Note that the groove in the sides is 'A in. up from the bottom edge. Step 2: It's important to set your box joint jig up right Mount the 'A in. brass key. and adjust the jig so the key is 'A ON C&6rts. OiuY »ET Jvi UP »o WES Mt^A PROM BL»-T?E Hewrwr ' vJF 4K ♦T&C.IC AflUMiT KEY * MCM( TUC WOUWIRtt TVit FvB.*V *v-OT <FiT* owe*. TXB C«.y. thsn M*,**. TUB. cajt. Fem. T>\e ic«vr Tin.' Woodworker's Journal |