Woodworker's Journal 1993-17-5, страница 60

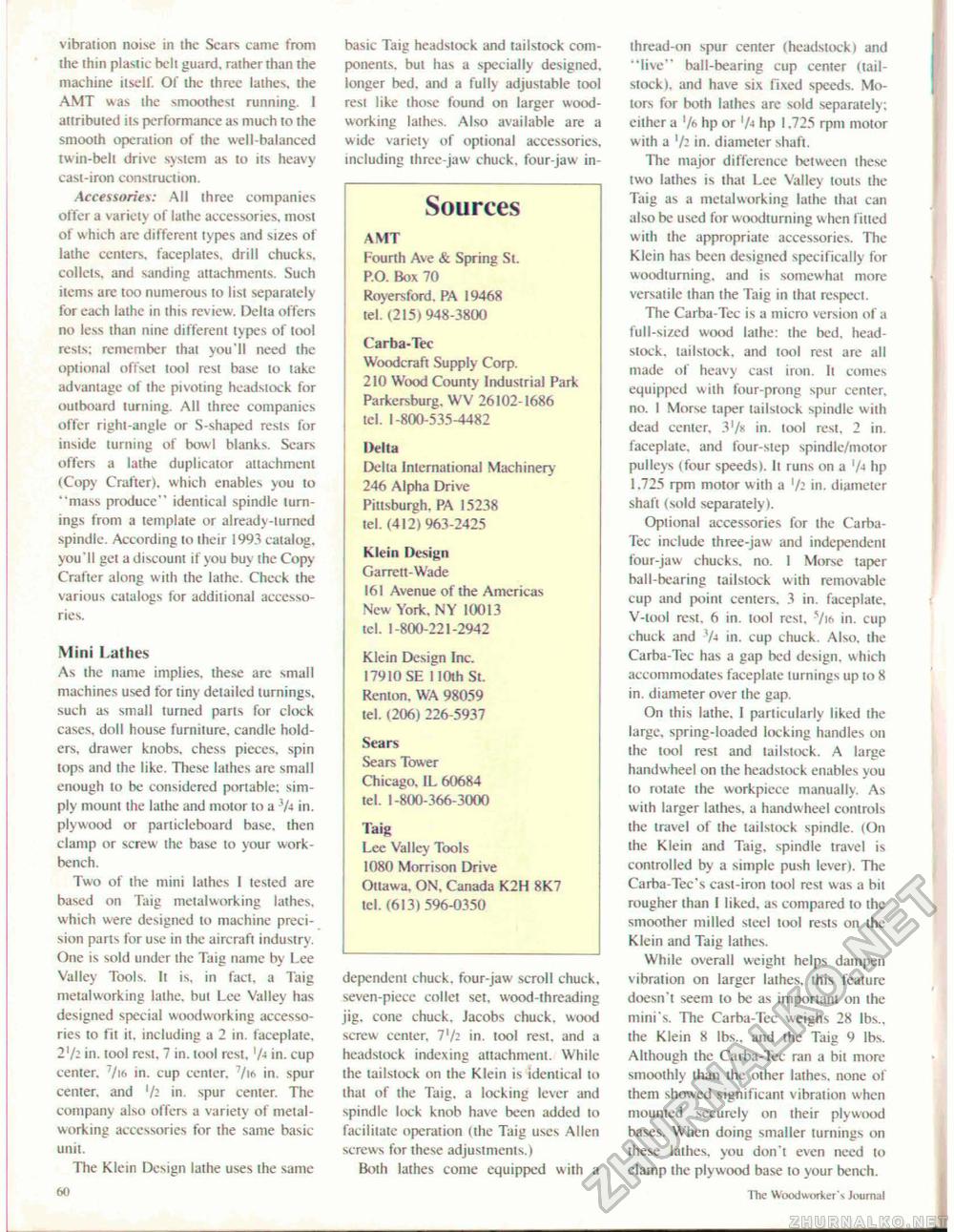

vibration noise in the Scars came from the thin plastic belt guard, rather than the machine itself. Of the three lathes, the AMT was the smoothest running. I attributed its performance as much to the smooth operation of the well-balanced twin-belt drive system as to its heavy cast-iron construction. Accessories: All three companies offer a variety of lathe accessories, most of which are different types and sizes of lathe centers, faceplates, drill chucks, collets, and sanding attachments. Such items are too numerous to list separately for each lathe in this review. Delta offers no less than nine different types of too! rests; remember that you'll need the optional offset tool rest base to lake advantage of the pivoting headstock for ouI hoard turning. All three companies offer right-angle or S-shaped rests for inside turning of bowl blanks. Sears offers a lathe duplicator attachment (Copy Crafter). which enables you to "mass produce" identical spindle turnings from a template or already-turned spindle. According to their 1993 catalog, you'll get a discount if you buy the Copy Crafter along with the lathe. Check the various catalogs for additional accessories. Mini Lathes As the name implies, these are small machines used for tiny detailed turnings, such as small turned parts for clock cases, doll house furniture, candle holders, drawer knobs, chess pieces, spin lops and Ihe like. These lathes are small enough to be considered portable; simply mount the lathe and motor to a 'A in. plywood or particleboard base, then clamp or screw the base to your workbench. Two of the mini lathes I tested are based on Taig metalworking lathes, which were designed to machine precision parts for use in the aircraft industry. One is sold under the Taig name by Lee Valley Tools. It is, in fact, a Taig metalworking lathe, but Lee Valley has designed special woodworking accessories to fit it. including a 2 in. faceplate. 2'A in. tool rest. 7 in. tool rest, 'A in. cup center, 7/i<> in. cup center. 1/\t. in. spur center, and lA in. spur center. The company also offers a variety of metalworking accessories for the same basic unit. The Klein Design lathe uses the same 60 basic Taig headstock and tailstock components. but has a specially designed, longer bed. and a fully adjustable tool rest like those found on larger woodworking lathes. Also available are a wide variety of optional accessories, including three-jaw chuck, four-jaw in- Sources AMT Fourth Ave & Spring St. P.O. Box 70 Royersford. PA 19468 tel. (215) 948-3800 Carba-Tec Woodcraft Supply Corp. 210 Wood County Industrial Park Parkersburg, WV 26102-1686 tel. 1-800-535-4482 Delta Delta International Machinery 246 Alpha Drive Pittsburgh. PA 15238 tel. (412) 963-2425 Klein Design Garrett-Wade 161 Avenue of the Americas New Yoric. NY 10013 tel. 1-800-221-2942 Klein Design Inc. 17910 SE 110th St. Renton. WA 98059 tel. (206) 226-5937 Sears Sears Tower Chicago, IL 60684 tel. 1-800-366-3000 Taig Lee Valley Tools 1080 Morrison Drive Ottawa, ON, Canada K2H 8K7 tel. (613)596-0350 dependent chuck, four-jaw scroll chuck, seven-piece collet set, wood-threading jig. cone chuck. Jacobs chuck, wood screw center, 7'A in. tool rest, and a headstock indexing attachment. While the tailstock on the Klein is identical to that of the Taig. a locking lever and spindle lock knob have been added to facilitate operation (the Taig uses Allen screws for these adjustments.) Both lathes come equipped with a thread-on spur center (headstock) and "live" ball-bearing cup center (tail-stock), and have six fixed speeds. Motors for both lathes are sold separately; either a '/ft hp or 'A hp 1,725 rpm motor with a 'A in. diameter shaft. The major difference between these two lathes is that Lee Valley louts the Taig as a metalworking lathe that can also be used for woodturning when fitted with the appropriate accessories. The Klein has been designed specifically for woodturning, and is somewhat more versatile than the Taig in that respect. The Carba-Tec is a micro version of a full-sized wood lathe: the bed, head-stock. tailstock, and tool rest are all made of heavy cast iron. Il comes equipped with four-prong spur center, no. 1 Morse taper tailstock spindle wiih dead center, 3'A in. tool rest. 2 in. faceplate, and four-step spindle/motor pulleys (four speeds). It runs on a 'A hp 1.725 rpm motor with a 'A in. diameter shall (sold separately). Optional accessories for the Carba-Tec include three-jaw and independent four-jaw chucks, no. I Morse taper ball-bearing tailstock with removable cup and point centers. 3 in. faceplate. V-tool rest, 6 in. lool rest, sAo in. cup chuck and 'A in. cup chuck. Also, the Carba-Tec has a gap bed design, which accommodates faceplate turnings up lo 8 in. diameter over the gap. On this lathe. I particularly liked the large, spring-loaded locking handles on ihe tool rest and tailstock. A large handwheel on ihe headstock enables you lo rotate the workpiece manually. As with larger laihes, a handwheel controls ihe travel of the tailstock spindle. (On the Klein and Taig, spindle travel is controlled by a simple push lever). The Carba-Tec's cast-iron tool rest was a bil rougher than I liked, as compared lo ihe smoother milled sieel tool rests on the Klein and Taig laihes. While overall weight helps dampen vibration on larger lathes, this feature doesn't seem to be as important on ihe mini's. The Carha-Tec weighs 28 lbs., the Klein 8 lbs., and the Taig 9 lbs. Although the Carba-Tec ran a bit more smoothly than the other lathes, none of them showed significant vibration w hen mounted securely on their plywood bases. When doing smaller turnings on these lathes, you don't even need to clamp the plywood base to your bench. The Woodw orker'5 Journal |