Woodworker's Journal 1993-17-5, страница 58

Make Specifications Chart /P/W Make

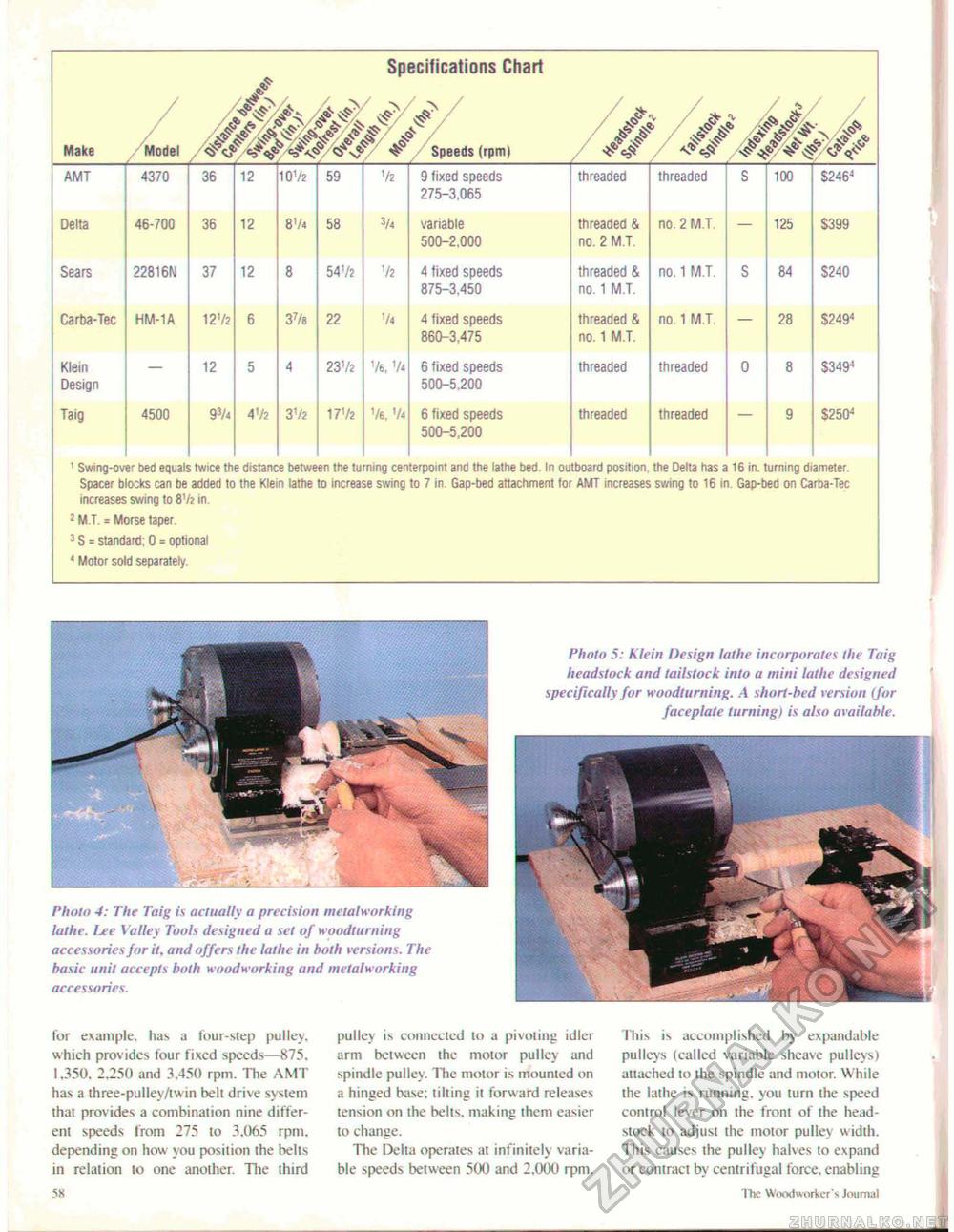

1 Swing-over bed equals twice the distance between the turning centerpoint and the lathe bed. In outboard position, the Delta has a 16 in. turning diameter. Spacer blocks can be added to the Klein lathe lo increase swing to 7 in. Gap-bed attachment lor AMT increases swing to 16 in. Gap-bed on Carba-Tec increases swing to 8V? in. 2 M.T.« Morse taper 3 S = standard; 0 = optional 4 Motor sold separately. Photo 4: The Taig is actually a precision metalworking lathe. Ijee Valley Tools designed a set of woodturning accessories for it. and offers the lathe in both versions. The basic unit accepts both woodworking and metalworking accessories. Photo 5: Klein Design lathe incorporates the Taig headstock and tailstock into a mini lathe designed specifically for woodturning. A short-bed version (for faceplate turning) is also available. tor example, has a four-step pulley, which provides four fixed speeds—875, 1.350. 2.250 and 3.450 rpm. The AMT has a three-pulley/lwin hell drive system thai provides a combination nine different speeds from 275 to 3,065 rpm. depending on how you position ihe belts in relation lo one another. The third 5K pulley is connected lo a pivoting idler arm between the motor pulley and spindle pulley. The motor is mounted on a hinged base: tilling il forward releases tension on the belts, making them easier to change. The Delta operates at infinitely variable speeds between 500 and 2,000 rpm. This is accomplished by expandable pulleys (called variable sheave pulleys) attached to the spindle and motor. While the lathe is running, you turn the speed control lever on the front of the head-stock to adjust ihe motor pulley width. This causes the pulley halves to expand or contract by centrifugal force, enabling The Woodworker's Journal |