Woodworker's Journal 1993-17-5, страница 56

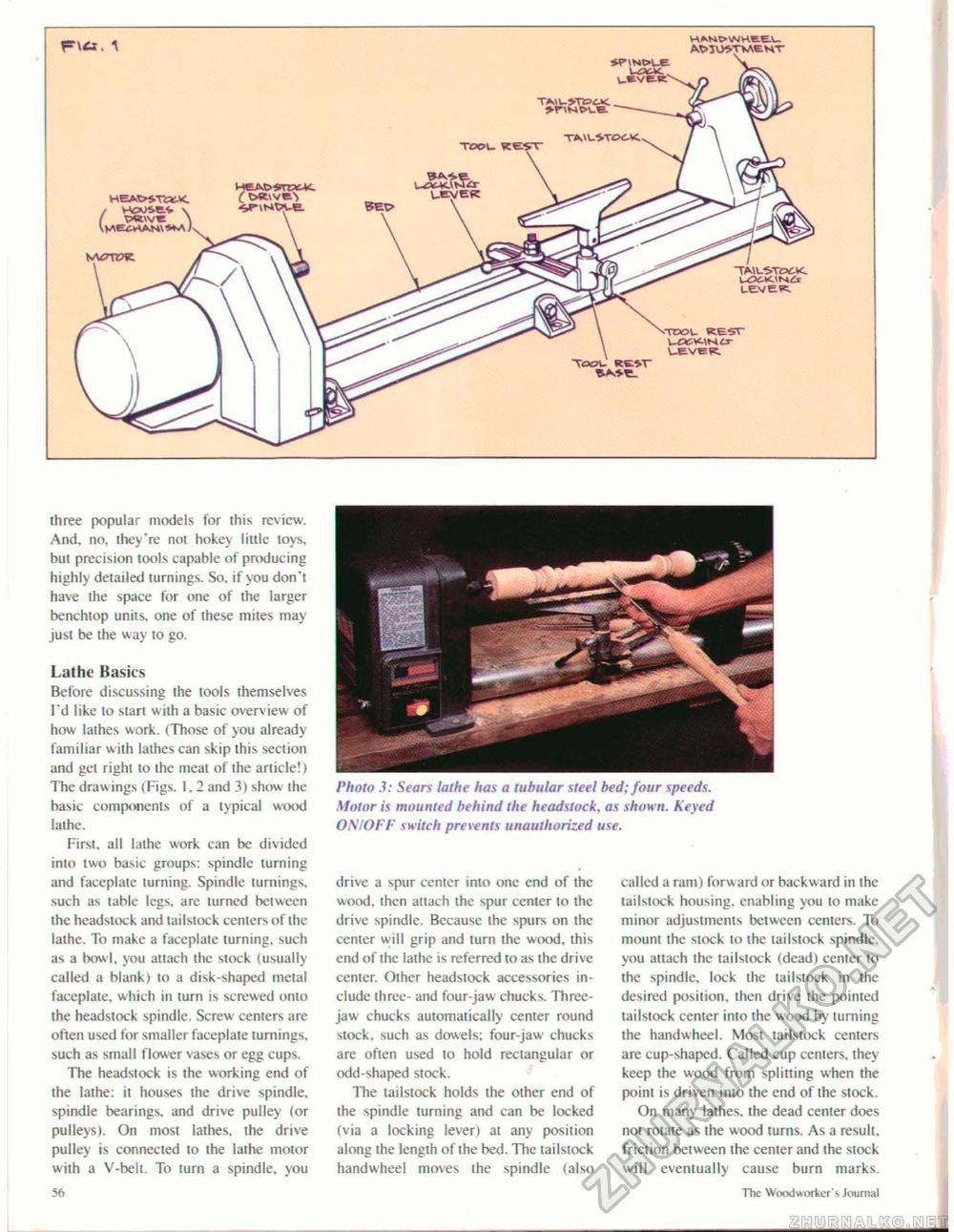

Photo .?: Sears lathe has a tubular steel bed; four speeds. Motor is mounted behind the headstock, as shown. Keyed OX/OFF switch prevents unauthorized use. three popular models for this review. And, no, they're not hokey little toys, but precision tools capable of producing highly detailed turnings. So, if you don't have the space for one of the larger benchtop units, one of these mites may just be the way to go. Lathe Basics Before discussing the tools themselves I'd like to start with a basic overview of how lathes work. (Those of you already familiar with lathes can skip this section and gel right to the meal of the article!) The drawings (Figs. 1. 2 and 3) show the basic components of a typical wood lathe. First, all hilhe work can be divided inio two basic groups: spindle turning and faceplate turning. Spindle turnings, such as table legs, arc turned belween the headstock and tailstock ccnlcrs of the lathe. To make a faceplate turning, such as a bowl, you attach the stock (usually called a blank) to a disk-shaped metal faceplate, which in turn is screwed onto the headstock spindle. Screw centers are often used for smaller faceplate turnings, such as small flower vases or egg cups. The headstock is the working end of the lathe: it houses the drive spindle, spindle bearings, and drive pulley (or pulleys). On most lathes, the drive pulley is connected to the lathe motor with a V-belt. To turn a spindle, you 56 drive a spur center into one end of the wood, then attach the spur center to the drive spindle. Bccause the spurs on the center will grip and turn the wood, this end of the lathe is referred to as the drive center. Other headstock accessories include three- and four-jaw chucks. Three-jaw chucks automatically center round stock, such as dowels; four-jaw chucks are often used to hold rectangular or odd-shaped stock. The tailstock holds the other end of the spindle turning and can be locked (via a locking lever) at any position along ihe length of the bed. The tailstock handwheel moves ihe spindle (also called a ram) forw ard or backward in the tailstock housing, enabling you to make minor adjustments between centers. To mount the stock to the tailstock spindle, you attach the tailstock (dead) center to the spindle, lock the tailstock in the desired posiiion, then drive the pointed tailstock center into the wood by turning the handwheel. Most tailstock centers are cup-shaped. Called cup centers, they keep the wood from splitting when the point is driven into ihe end of the stock. On many lathes, the dead center does noi rotate as the wood turns. As a result, friction between the center and the stock will eventually cause burn marks. The Woodw orker'5 Journal |