Woodworker's Journal 1993-17-5, страница 59

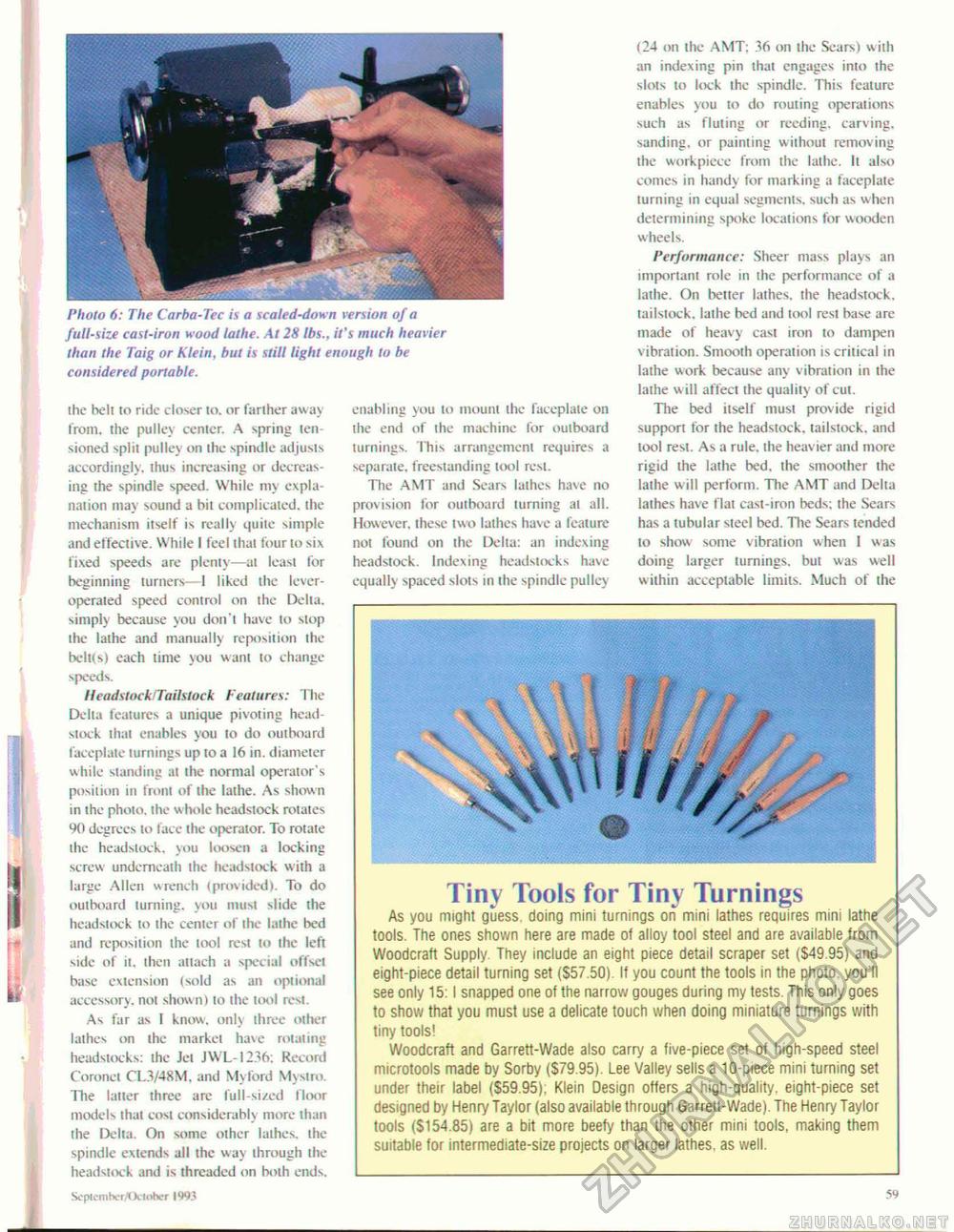

Photo 6: The Carba-Tec is a scaled-down version of a full-size cast-iron wood lathe. At 28 lbs., it's much heavier than the Taig or Klein, but is still light enough to be considered portable. the belt to ride closcr to. or farther away from, the pulley center. A spring ten-sioned split pulley on the spindle adjusts accordingly, thus increasing or decreasing the spindle speed. While my explanation may sound a bit complicated, the mechanism itself is really quite simple and effective. While I feel that four to six fixed speeds are plenty—at least for beginning turners-—1 liked the lever-operated speed control on the Delta, simply because you don't have to stop the lathe and manually reposition the bell(s) each time you want to change-speeds. UeadstockiTailstock Features: The Delta features a unique pivoting head-stock that enables you lo do outboard faceplate turnings up to a 16 in. diameter while standing at the normal operator's position in front of the lathe. As shown in the photo, ihe w hole headstock rotates 90 degrees to face the operator. To rotate the headstock, you loosen a locking screw underneath the headstock with a large Allen wrench (provided). To do outboard turning, you must slide the headstock to ihe center of the lathe bed and reposition the loo! rest to the left side of it. then attach a special offset base extension (sold as an optional accessory, not shown) to the tool rest. As far as I know, onh three other lathes on the market have rotating headstocks: ihe Jet JWL-1236: Record Coronet CO/48 M. and My ford Mystro. The latter three arc full-sized floor models that cost considerably more than the Delta. On some other lathes, the spindle extends all the way through the headstock and is threaded on both ends. enabling you to mount the faceplate on the end of ihe machine for outboard turnings. This arrangement requires a separate, freestanding tool rest. The AMT and Sears lathes have no provision for outboard turning at alt. However, these two lathes have a feature not found on the Delta: an indexing headstock. Indexing headstocks have equally spaced slots in the spindle pulley (24 on the AMT: 36 on the Sears) with an indexing pin that engages into the slots lo lock the spindle. This feature enables you to do routing operations such as fluting or reeding, carving, sanding, or painting without removing the workpiece from the lathe. It also comes in handy for marking a faceplate turning in equal segments, such as when determining spoke locations for wooden wheels. Performance: Sheer mass plays an important role in the performance of a lathe. On better lathes, the headstock, tailstock. lathe bed and lool rest base are made of heavy cast iron to dampen vibration. Smooth operation is critical in lathe work because any vibration in ihe lathe w ill affect the quality of cut. The bed itself must provide rigid support for the headstock. tailstock. and lool rest. As a rule, ihe heavier and more rigid the lathe bed, the smoother the lathe will perform. The AMT and Delta lathes have flat cast-iron beds; the Sears has a tubular steel bed. The Sears tended lo show some vibration when I was doing larger turnings, but was well within acceptable limits. Much of the Tiny Tools for Tiny Turnings As you might guess, doing mini turnings on mini lathes requires mini lathe tools. The ones shown here are made of alloy tool steel and are available from Woodcraft Supply. They include an eight piece detail scraper set ($49 95) and eight-piece detail turning set (S57.50). If you count the tools in the photo, you'll see only 15:1 snapped one of the narrow gouges during my tests. This only goes to show that you must use a delicate touch when doing miniature turnings with tiny tools! Woodcraft and Garrett-Wade also carry a five-piece set of high-speed steel microtools made by Sorby ($79.95). Lee Valley sells a 10-piece mini turning set under their label (S59.95); Klein Design offers a high-quality, eight-piece set designed by Henry Taylor (also available through Garrett-Wade). The Henry Taylor tools ($154.85) are a bit more beefy than the other mini tools, making them suitable for intermediate-size projects on larger lathes, as well. September October IW |