Woodworker's Journal 1993-17-6, страница 30

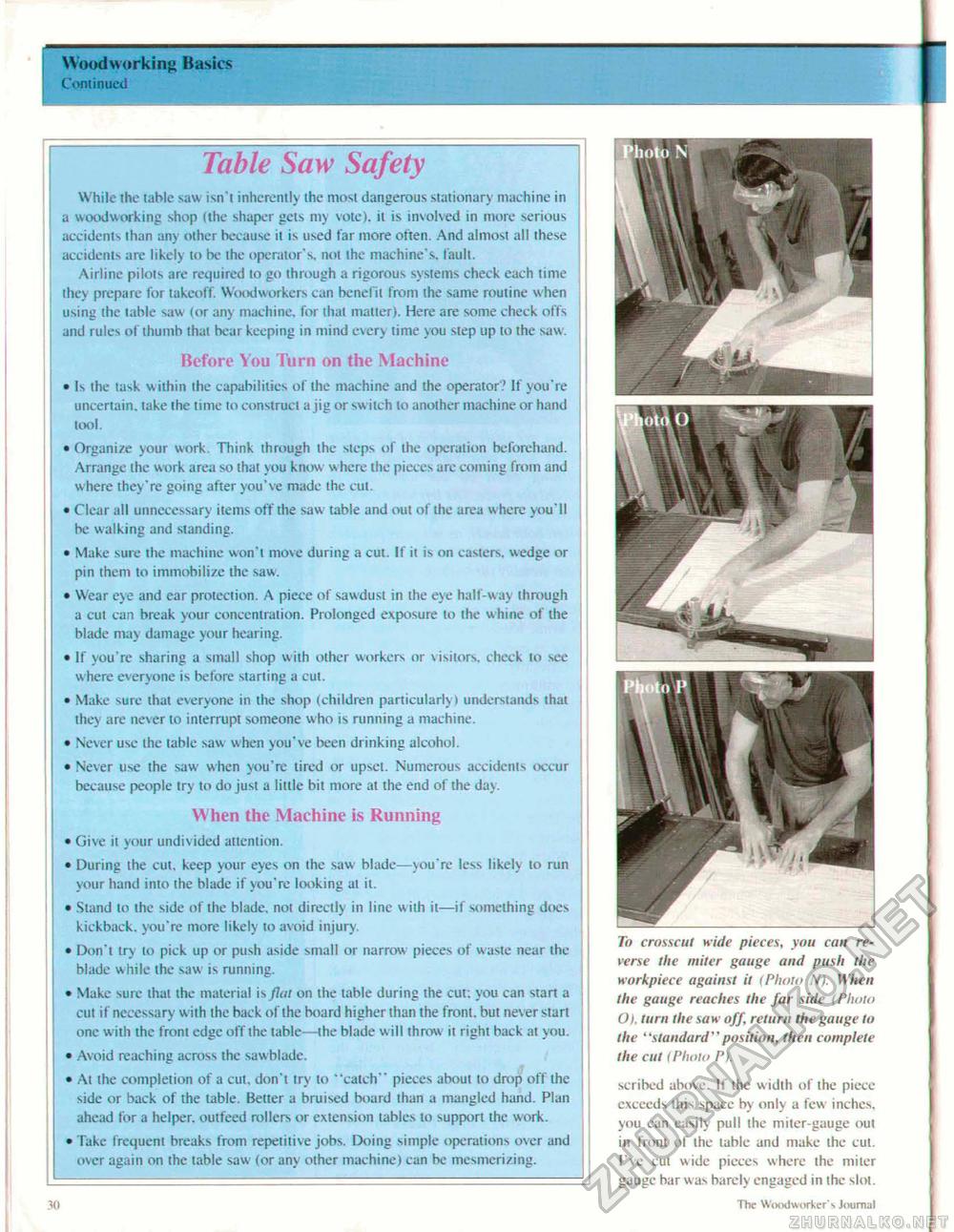

Woodworking Basics Continued Table Saw Safety While the fable saw isn't inherently the most dangerous stationary machine in a woodworking shop (the shaper gets my vole), it is involved in more serious accidents than any other because it is used far more often. And almost all these accidents are likely to be the operator's, not the machine7s. fault. Airline pilots are required lo go through a rigorous systems check each time I hey prepare for takeoff. Woodworkers can benefit from the same routine when using the table saw (or any machine, for thai matter). Here are some check ofTs and rules of thumb that bear keeping in mind every time you step up to the saw. Before You Turn on the Machine • Is the task within the capabilities of the machine and the operator? If you're uncertain, lake the time to construct a jig or sw itch 10 another machine or hand tool. • Organize your work. Think through the steps of the operation beforehand. Arrangc the work area so that you know where the pjcces are coming from and where they're going after you've made the cut. • Clear all unnecessary items off the saw table and out of die area where you'll be walking and standing. • Make sure the machine won't move during a cut. If it is on casters, wedge or pin them lo immobilize the saw • Wear eye and ear protection. A piece of sawdust in the eye half-way through a cut can break your concentration. Prolonged exposure to the wlnne of the blade may damage your hearing. • If you're sharing a small shop with other workers or visitors, check lo see w here everyone is before starling a cut. • Make sure that everyone in the shop (children particularly 1 understands that they are never to interrupt someone who is running a machine. • Never use the table saw w hen you've been drinking alcohol. • Never use the saw when you're tired or upset. Numerous accidents occur because people try to do just a little bit more at the end of the day. When the Machine is Running • Give it your undivided attention. • During ihe cut. keep your eyes on the saw blade—you're less likely to run your hand into the blade if you're looking at it. • Stand lo the side of the blade, not directly in line with it—if something does kickback, you're more likely to avoid injury. • Don't try to pick up or push aside small or narrow pieces of waste near the blade while the saw is running. • Make sure that the material is flat on the table during the cut: you can start a cut if necessary with the back of the board higher than the front, but never start one with the front edge off the table—the blade w ill throw it right hack at you. • Avoid reaching across the saw blade. • Ai the completion of a cut, don'i try lo "catch" pieces about lo drop off the side or back of the table. Better a bruised board than a mangled hand. Plan ahead for a helper, outfeed rollers or extension tables to support the work. • Take frequent breaks from repetitive jobs. Doing simple operations over and over again on the table saw (or any other machine) can be mesmerizing. 30 To crosscut wide pieces, you can reverse the miter gauge and push the workpiece against it (Photo N). W hen (he gauge reaches the Jar side (Photo O). turn the saw off, return the gauge lo the "standard1' position, then complete the cut (Photo P). scribed above. If the w idth of the piece exceeds this space by only a few inches, you can easily pull the miter-gauge out in front of the table and make the cut. I've cut wide pieccs where the miler gauge bar was barely engaged in the slot. The Wixnlwiifker's Journal |