Woodworker's Journal 1993-17-6, страница 55

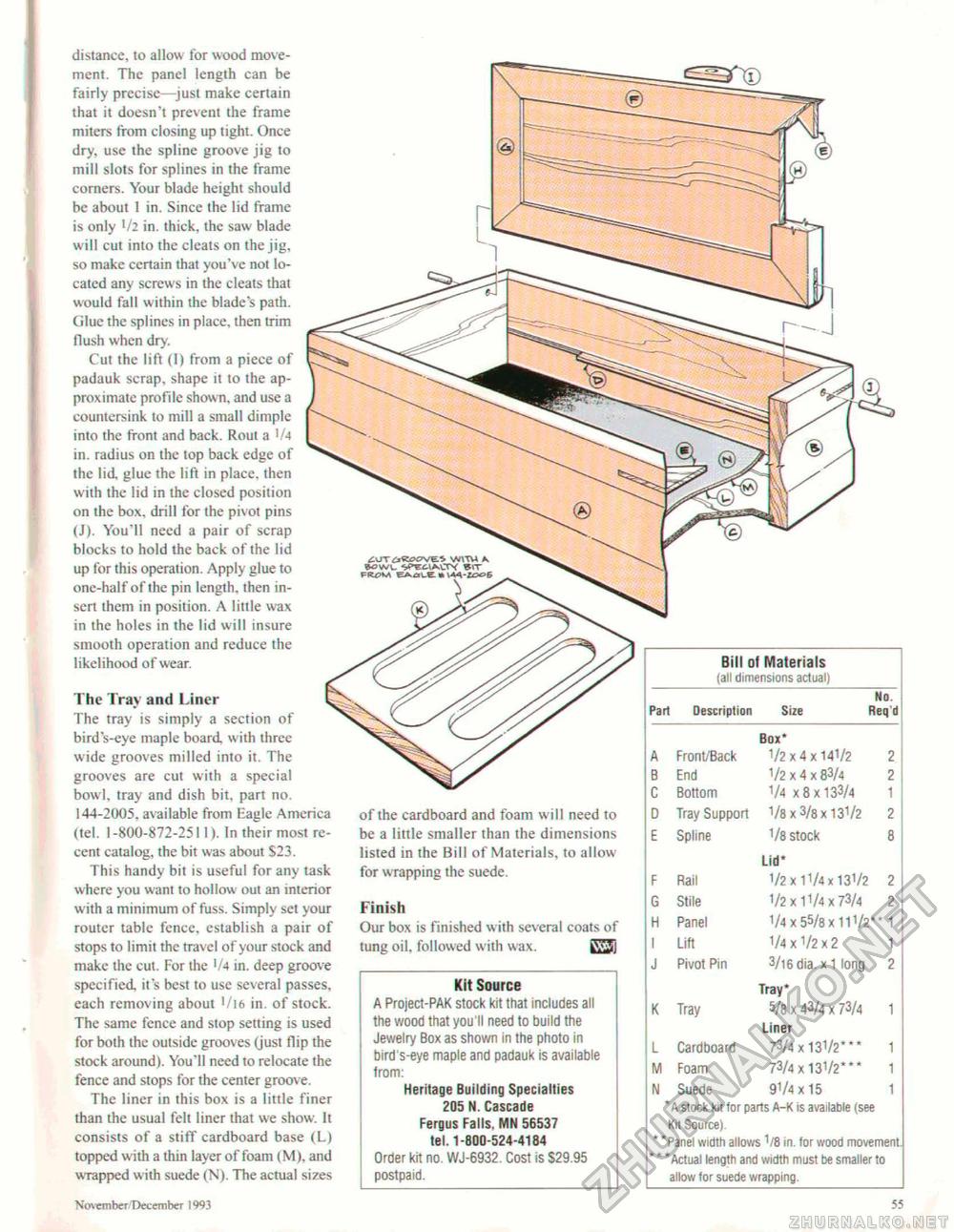

Novcmber/December 1993 55 Kit Source A Project-PAK stock kit that includes all the wood that you 'll need to build the Jewelry Box as shown in the photo in bird's-eye maple and padauk is available Irom: Heritage Building Specialties 205 N. Cascade Fergus Falls. MN 56537 tel. 1-800-524-4184 Order kit no. WJ-6932. Cost is S29.95 postpaid. Bill ol Materials (all dimensions actual) Part Description Size

N Suede 974x15 1 * A stock kit for parts A-K is available (see Kit Source). * 'Panel width allows 1/8 in. lor wood movement. * * "Actual length and width must be smaller to allow (or suede wrapping. Part Description Size distance, to allow for wood movement. The panel length can be fairly precise—just make certain that it doesn't prevent the frame miters from closing up tight. Once dry, use the spline groove jig to mill slots for splines in the frame corners. Your blade height should be about 1 in. Since the lid frame is only '/2 in. thick, the saw blade will cut into the cleats on the jig, so make certain that you've not located any screws in the cleats that would fall within the blade's path, (ilue the splines in place, then trim flush when dry. Cut the lift (I) from a piece of padauk scrap, shape it to the approximate profile shown, and use a countersink lo mill a small dimple into the front and back. Roul a '/4 in. radius on the top back edge of the lid. glue the lift in place, then with the lid in the closed position on the box. drill for the pivot pins (J). You'll need a pair of scrap blocks to hold the back of the lid up for this operation. Apply glue to one-half of the pin length, then insert them in position. A little wax in the holes in the lid will insure smooth operation and reduce the likelihood of wear. The Tray and Finer The tray is simply a section of bird's-eye maple board with three wide grooves milled into it. The grooves are cut with a special bowl, tray and dish bit. part no. 144-2005. available from Eagle America (tel. 1-800-872-2511). In their most recent catalog, the bit was about S23. This handy bit is useful for any task where you want to hollow out an interior with a minimum of fuss. Simply set your router table fence, establish a pair of stops to limit the travel of your stock and make the cut. For the >/4 in. deep groove specified, it's best to use several passes, each removing about '/l6 in. of stock. The same fence and stop setting is used for both the outside grooves (just flip the stock around). You'll need to relocate (he fence and stops for the center groove. The liner in this box is a little finer than the usual felt liner that we show. It consists of a stiff cardboard base (L) topped with a thin layer of foam (M). and WTapped with suede (N). The actual sizes of the cardboard and foam w ill need to be a little smaller than the dimensions listed in the Bill of Materials, to allow for wrapping the suede. Finish Our box is finished with several coats of tung oil, followed with wax. tteii |