Woodworker's Journal 1993-17-6, страница 66

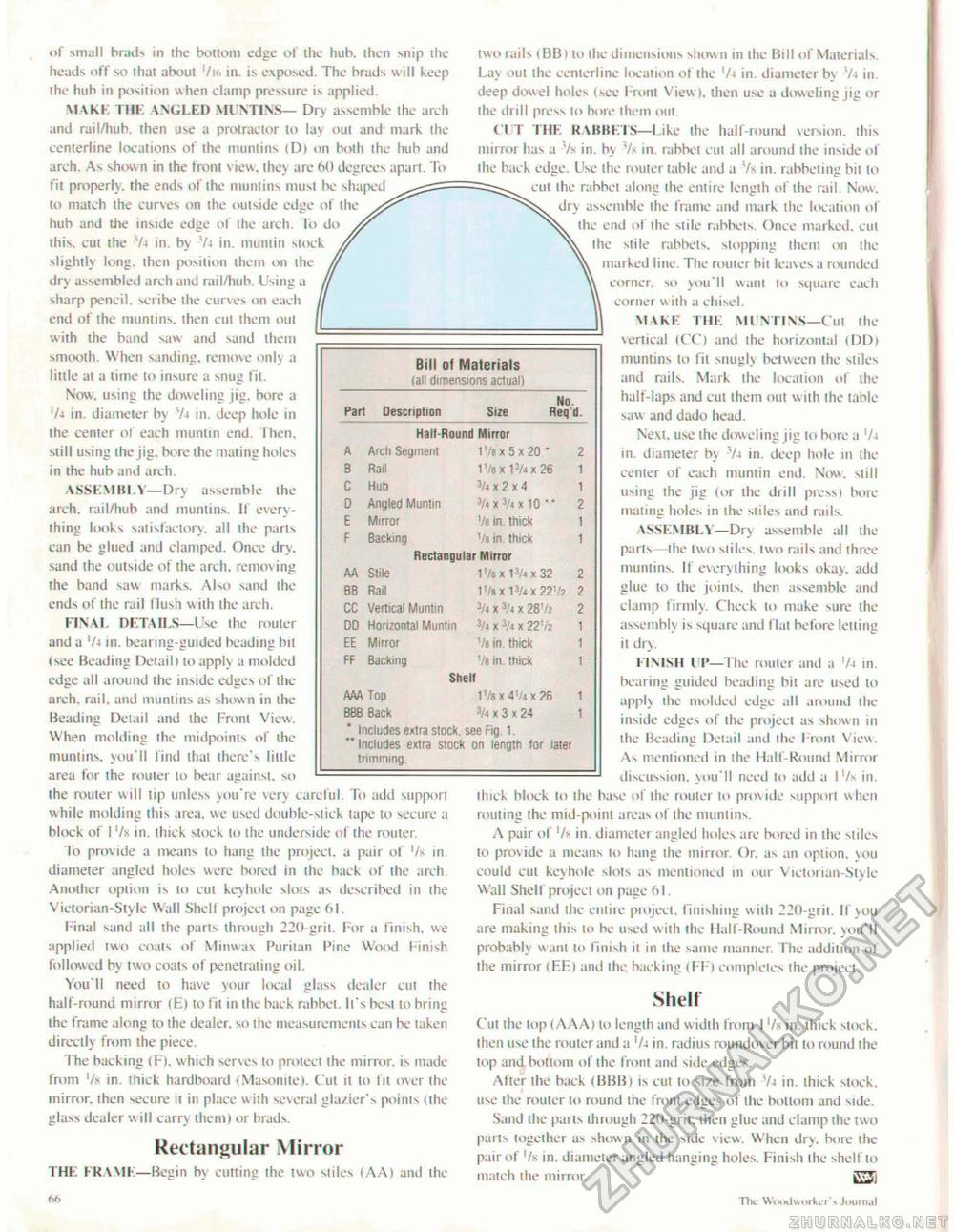

of small hrad». in the bottom edge of the hub. then snip the heads off so that about '/ii> in. is exposed. The brads will keep the huh in posiiion when clamp pressure is applied. MAKE THE ANGLED MUNTINS— Dry assemble the areh and rail/huh, then use a protractor to lay out and mark the centeriine locations of the muntins (D) on both the hub and arch. As shown in the front view, they are 60 degrees apart. To fit properly, the ends of the muntins must be shaped to match the curves on the outside edge of the hub and the inside edge of the arch. To do this, cul the V-i in by 7t in. muniin stock slightly long, then position them on the dry assembled arch and rail/hub. Using a sharp pencil, scribe the curves on each end of the muntins. then cut them out with the band saw and sand them smooth. When sanding, remove only a little al a time lo insure a snug fil. Now, using the doweling jig. bore a '/j in. diameter by 7j in. deep hole in the center of each muniin end. Then, still using the jig. bore the mating holes in Ihe hub and arch. ASSEMBLY—Dry assemble the arch, rail/hub and muntins. If everything looks satisfactory, all the purls can be glued and clamped. Once dry. sand the outside of the arch, removing the band saw marks. Also sand (he ends of the rail flush with ihe arch. FINAL DETAILS—Use the router and a lU in. bearing-guided beading bil (see Beading Detail) to apply a molded edge all around the inside edges of the arch. rail, and muntins as shown in the Beading Detail and the From View. When molding ihe midpoints of the muntins. you'll find thai there's little area for the router lo bear against, so

two rails iBBl lo ihe dimensions shown in the Bill of Materials. Lay out the centeriine location of the 1 /J in. diameter by 7i in. deep dowel holes (see Front View), then use a doweling jig or the drill press lo bore them out. CUT THE RABBETS—Like the half-round version, this mirror has a 7s in. by 7s in. rabbet cul all around the inside of ihe back edge. Use ihe router table and a 7s in. rabbeting bit to cut Ihe rabbet along the entire lengih of the rail. Now, dry assemble the frame and mark the location of the end of the stile rabbets. Once marked, cut the stile rabbets, stopping them on the marked line. The router hit leav es a rounded corner, so you'll want to square each corner w ith a chisel. MAKE I HE Ml NUNS—C ul the vertical (CC) and the horizontal <DD> muntins lo fit snugly between the stiles and rails. Mark the location of the half-laps and cut them out with the table saw and dado head. Next, use ihe doweling jig to bore a '/j in. diameter by 7j in. deep hole in the center of cach muniin end. Now. still using the jig (or ihe drill press) bore-mating holes in ihe stiles and rails. ASSEMBLY—Dry assemble all the parts ihe two stiles, two rails and three muntins. If everything looks okay, add glue to ihe joints, then assemble and clamp firmly. Check lo make sure the assembly is square and flat before letting it dry. FINISH UP—The router and a 'A in. bearing guided beading bit are used to apply the molded edge alt around the inside edges of the project as shown in the Beading Detail and the Front View. As mentioned in the Half-Round Mirror discussion. u>u*H need to add a )'/* in. the router will tip unless you're very careful. To add support w hile molding this area, we used double-stick tape to secure a block of I '/s in. thick stock to Ihe underside of ihe router. To provide a means to hang the project, a pair of Vk in. diameter angled holes were bored in the back of Ihe arch. Another option is to cul keyhole slois as described in the Victorian-Style Wall Shelf project on page 61. Final sand all the parts through 220-gril. For a finish, we applied two coals of Mimvax Puriian Pine Wood Finish followed by two coats of penetrating oil. You'll need lo have your local glass dealer cut the half-round mirror (E) to fit in the back rabbet. It's best to bring the frame along to the dealer. so the measurements can be taken directly from the piece. The backing (F). which serves lo protect ihe mirror, is made from Vh in. thick hardboard (Masonite). Cul il to fit over the mirror, then secure it in place with several glazier's points (the glass dealer w ill carry them) or hrads. Rectangular Mirror THK FRAME—Begin h\ cutting the two stiles (AA) and ihe thick block lo ihe base of the router to provide support when routing the mid-point areas of the muntins. A pair of '/k in. diameter angled holes are bored in the stiles to provide a means lo hang the mirror. Or. as an option, you could cut keyhole slots as mentioned in our Victorian-Slyle Wall Shelf project on page 61 Final sand (he entire project, finishing with 220-grit. If you are making this to be used with the Half-Round Mirror, you'll probably want lo finish it in the same manner. The addition of the mirror (EEl and the backing (FF) completes the project. Shelf Cut the lop (AAA) to length and width from I Vk in. thick stock, then use the router and a Vj in. radius roundover bit to round the top and bottom of the front and side edges. Alter the back (BBB) is cut to size from 7j in. thick stock, use (he router to round the front edges of tile bottom and side. Sand the parts through 220-grit, then glue and clamp the two parts together as show n in ihe side view. When dr\. bore ihe pair of Vx in. diameter angled hanging holes. Finish the shelf to match the mirror. to nk. WtHKhwjrker's tihini,tI |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||