Woodworker's Journal 1994-18-1, страница 70

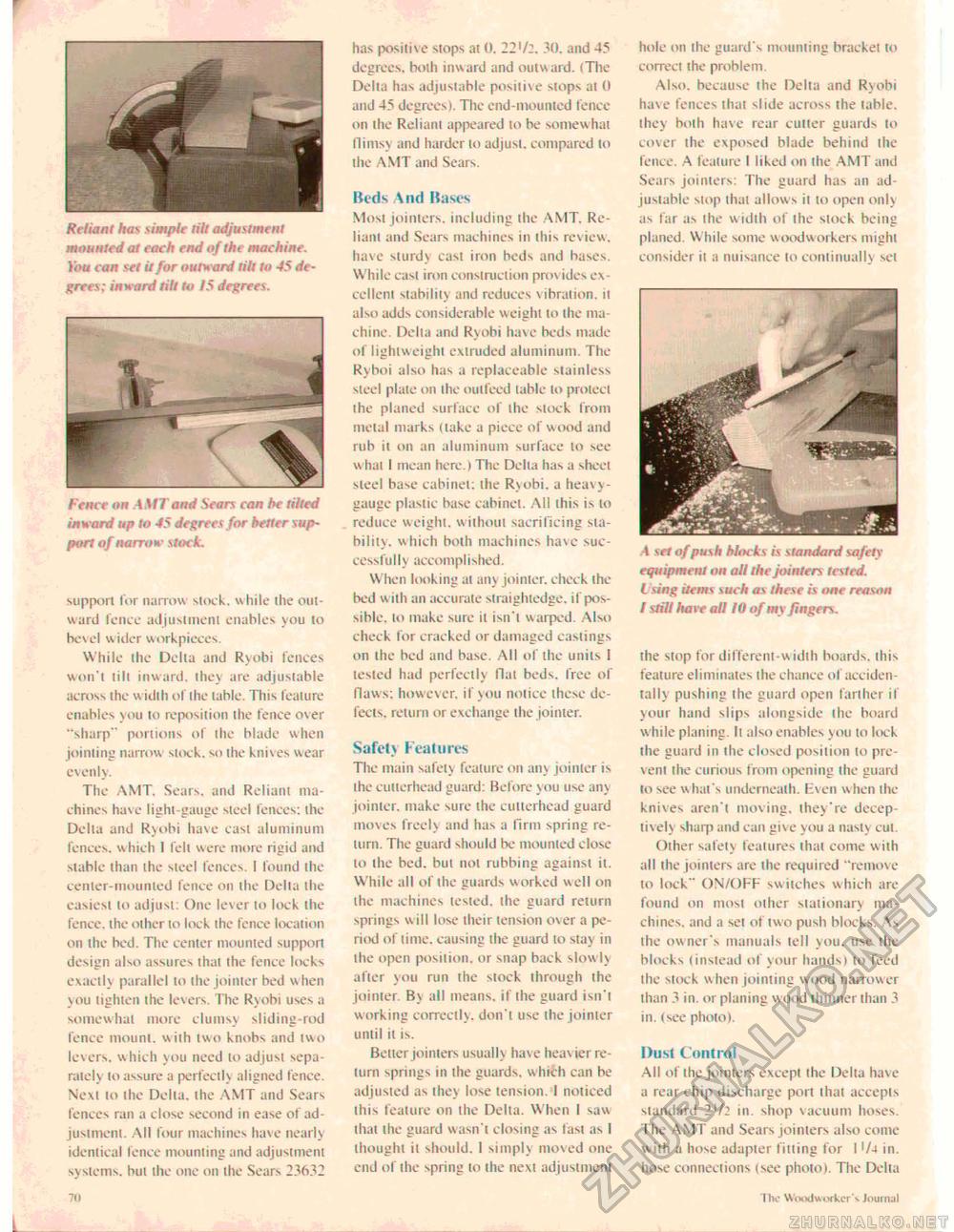

Reliant has simple tilt adjustment mounted at each end of the machine. You can set it for outward tilt to 45 degrees; inward till to 15 degrees. support for narrow stock, while the outward fence adjustment enables you to bevel wider workpieces. While the Delta and Rvobi fences won't tilt inward, they are adjustable across the width of the table. This feature enables you to reposition the fence over "sharp" portions of the blade when jointing narrow stock, so the knives wear evenly. The AMT. Sears, and Reliant machines have light-gauge steel fences; the Delta and Ryobi have cast aluminum fences, which 1 fell were more rigid and stable than the steel fences. I found the center-mounted fence on the Delta the easiest to adjust: One lever to lock the fence, the other to lock the fence location on the bed. The center mounted support design also assures thai the fence locks exactly parallel lo the jointer bed when you tighten ihe levers. The Ryobi uses a somewhat more clumsy sliding-rod fence mount, with two knobs and two levers, which you need lo adjust separately to assure a perfectly aligned fence. Next lo ihe Delia, the AMT and Sears fences ran a close second in ease of adjustment. All lour machines have nearly identical fence mounting and adjustment systems, but ihe one on ihe Sears 23632 70 has positive stops at 0. 2230, and 45 degrees, both inward and outward. (The Delta has adjustable positive slops at 0 and 45 degrees). The end-mounted fence on the Reliant appeared to be somewhat flimsy and harder lo adjust, compared lo the AMT and Sears. Beds And Bases Most jointers, including the AMT. Reliant and Sears machines in this review, have sturdy cast iron beds and bases. While casi iron construction prov ides excellent stability and reduces vibration, it also adds considerable weight lo ihe machine. Delia and Ryobi hav e beds made of lightweight extruded aluminum. The Ryboi also has a replaceable stainless sieel plate on the oulfeed table lo protect the planed surface of the stock from metal marks (lake a piece of wood and rub it on an aluminum surface to see w hat I mean here.) The Delia has a sheet steel base cabinet; ihe Rvobi. a heavj-gauge plastic base cabinet. All this is to reduce w eight, without sacrificing stability. which both machines have successfully accomplished. When looking at any jointer, check ihe bed with an accurate straightedge, if possible. to make sure il isn't warped. Also check for cracked or damaged castings on the bed and base. All of the units I tested had perfectly flat beds, free of flaws; however, if you notice these de-feels. return or exchange the joinier. Safely Features The main safely feature on any joinier is the cullerhead guard: Before you use any jointer, make sure the cutterhead guard moves freely and luis a firm spring return. The guard should be mounted close lo the bed. but not rubbing against il. While all of the guards worked well on the machines tested, the guard return springs will lose their tension over a period of lime, causing the guard lo stay in the open position, or snap back slow ly alier vou run the stock through ihe jointer By all means, if the guard isn't working correctly, don't use the jointer until it is. Better jointers usually have heav ier return springs in the guards, which can be adjusted as they lose tension. I noticed this feature on the Delta. When I saw that the guard wasn't closing as fast as I thought it should. I simply moved one end of the spring to ihe next adjustment hole on Ihe guard's mourning bracket lo correct the problem. Also, because the Delta and Ryobi have fences that slide across the lable. they both have rear cutter guards to cover ihe exposed blade behind the fence. A feature I liked on ihe AMT and Sears jointers; '["lie guard has an adjustable stop that allows it lo open only as far as the width of the stock being planed. While some woodworkers might consider it a nuisance lo continually sei .4 set of push blttcks is standard safety equipment on all the jointers tested. I sing items such as these is one reason 1 still Aoir all 10 of my fingers. the stop for different-width boards, this feature eliminates the chance of accidentally pushing ihe guard open farther if vour hand slips alongside the board while planing. It also enables you lo loc k the guard in the closed position to prevent the curious from opening ihe guard Hi see whafs underneath. Even when the knives aren't moving, they're deceptive!) sharp and can giv e you a nasty cul. Other safety features thai come with all the jointers are the required "remov e to lock" ON/OFF switches which are found on most other stationary machines, and a sel of two push blocks. As the owner's manuals tell you. use the blocks (instead of your hands) lo feed the stock when jointing wood narrower than 3 in. or planing w ood thinner than 3 in. (see photo). Dust Control All of the jointers except the Delta have a rear chip discharge port that accepts standard 21/: in. shop vacuum hoses. I he AMT and Sears jointers also come wiih a hose adapier fitting for 11/4 in. hose connections (see photo). The Delta The Wood*order's Journal Fence on AMT and Sears can he tilled inward up lo 45 degrees for better support of narrow stock, |