Woodworker's Journal 1994-18-1, страница 69

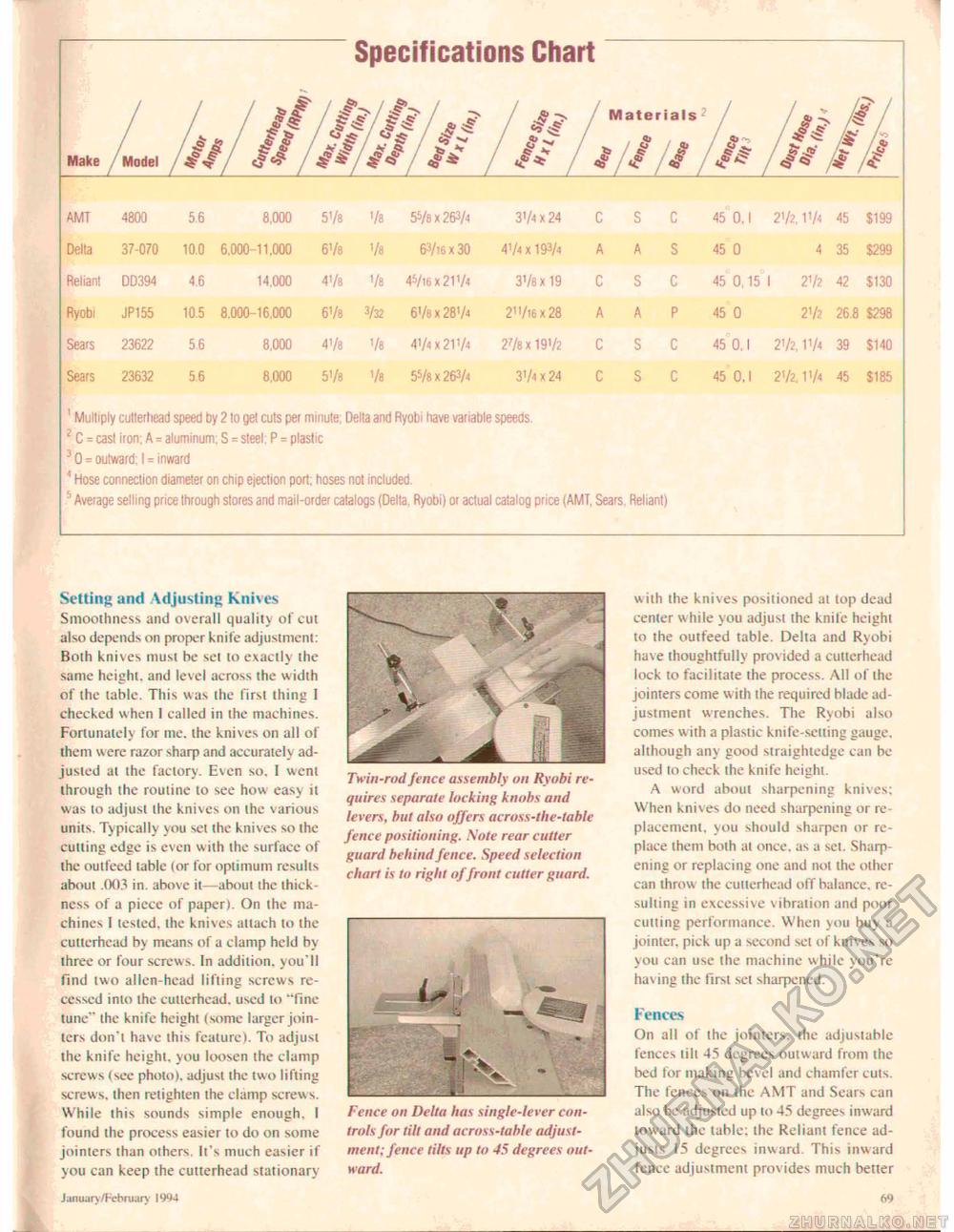

Specifications Chart

1 Multiply cutterhead speed by 2 to get cuts per minute; Delia and Ryobi have variable speeds. ; C = cast iron; A = aluminum; S = steel; P = plastic 3 0 = outward; I = inward 1 Hose connection diameter on ctitp ejection port; hoses not included. 6 Average selling price through stores and mail-order catalogs (Delta. Ryobi) or actual catalog price (AMT, Sears, Reliant) Setting and Ad justing Knives Smoothness and overall quality of cut also depends on proper knife adjustment: Both knives must be set to exactly the same height, and level across the width of the table. This was the first thing I checked when I called in the machines. Fortunately for me. the knives on all of them were razor sharp and accurately adjusted at the factory. Even so. I went through the routine to see how easy it was to adjust the knives on the v arious units. Typically you set the knives so the cutting edge is even with the surface of the outleed table (or for optimum results about .003 in. above it—about the thickness of a piece of paper). On the machines I tested, ihe kni\es attach to the cutterhead by means of a clamp held by three or four screws. In addition, you'll find two alien head lifting screws recessed into the cutterhead. used lo "line tune" the knife height (some larger jointers don't have this feature). To adjust the knife height, you loosen the clamp screws (see photo), adjust the two lifting screws, then relighten the clamp screws. While this sounds simple enough. I found ihe process easier to do on some joinlers than others. It's much easier if you can keep the cutterhead stationary Twin-rod fence assembly on Ryobi requires separate locking knobs and levers, but also ojfers across-the-table fence positioning. Note rear cutter guard behind fence. Speed selection chart is to right of front cutter guard. Fence on Delta has single-lever controls for tilt and across-table adjustment; fence tilts up to 45 degrees outward. with the knives positioned ai top dead center while you adjusi ihe knife height to the outfeed table. Delta and Ryobi have ihoughtfully provided a cuiierhead lock to facilitate the process. All of the jointers come with the required blade adjustment wrenches. The Ryobi also comes w ith a plastic knife-setting gauge, although any good straightedge can be used lo check the knife height. A word about sharpening knives; When knives do need sharpening or replacement, you should sharpen or replace them both at once, as a set. Sharpening or replacing one and noi the other can throw the cutterhead olT balance, resulting in excessive vibration and poor cutting performance. When you buy a jointer, pick up a second set of knives so you can use the machine while you're having (he firsi set sharpened. Fences On all of the jointers, the adjustable fences tilt 45 degrees outw ard from the bed for making bevel and chamfer culs. The fences on the AMT and Sears can also be adjusted up lo 45 degrees inward tow ard the table: the Reliant fence adjusts 15 degrees inward. This inward fence adjustment provides much better January/February 1994 69 |