Woodworker's Journal 1994-18-1, страница 66

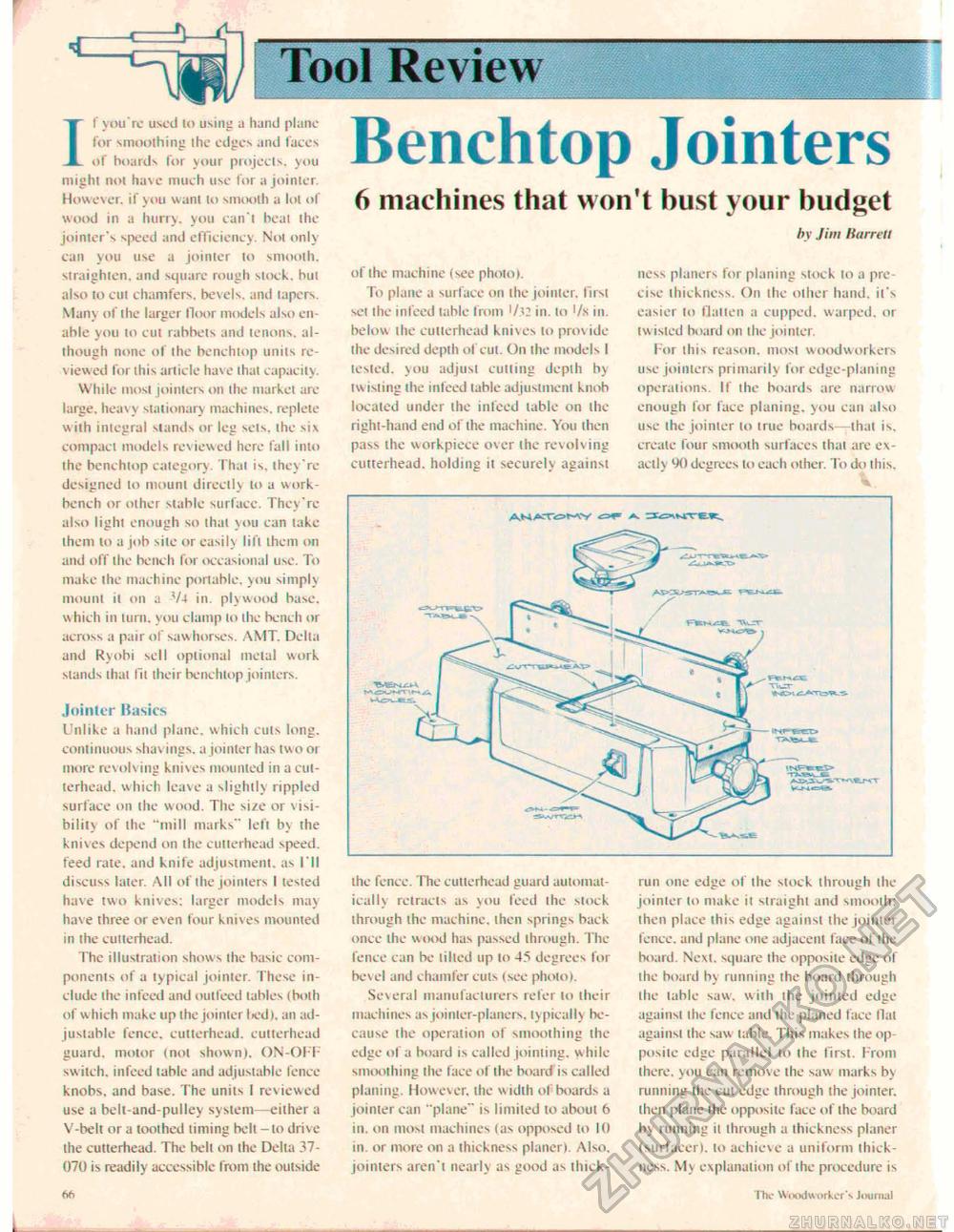

Tool Review If you're used to using a hand plane for smoothing (he edges and faces of hoards for your projects, you might not have much use for a jointer. However, if you want lo smooth a ltd of wood in a hurry, you can't beat the jointer's speed and efficiency. Not only can you use a jointer to smooth, straighten, and square rough slock, hut also to cut chamfers, bevels, and tapers. Many of the larger floor models also enable you lo cut rabbets and tenons, although none of the henchtop uniis reviewed for this article ha\ e that capacity. While most jointers on the market are large, heav y stationary machines, replete with integral stands or leg sets, the six compact models reviewed here fall inlo the henchtop category. Thai is. they're designed lo mount directly to a workbench or other stable surface. They 're also light enough so that you can lake them to a job site or easily lilt them on and off the bench for occasional use. To make ihe machine portable, vou simplv mount it on a V-l in. plywood base, which in turn, vou clamp lo the bench or across a pair of saw horses. AMT. Delta and Rvobi sell optional metal work stands thai fit iheir henchtop jointers. Jointer Basics Unlike a hand plane, w hich cuts long, continuous shav mgs. a jointer has two or more revolving knives mounted in a cui-terhead. which leave a slightly rippled surface on the wood. The size or visibility of the "mill marks" left by the knives depend on the cutterhead speed, feed rate, and knife adjustment, as I'll discuss later. All of the jointers I tested have two knives: larger models may hav e three or even four knives mounted in the cullerhead. "I he illustration shows Ihe basic components of a typical jointer. These include the infeed and oulfeed tables (both of w hich make up the jointer l>ed>. an adjustable fence, cutterhead. cullerhead guard, motor (not shown). ON-OFF switch, infeed (able and adjustable fence knobs, and base. The units I reviewed use a belt-and-pulley system—either a V-belt or a toothed liming belt—to drive the cutterhead. The hell on the Delta 37071) is readily accessible from the outside Mi Benchtop Jointers 6 machines that won't bust your budget of ihe machine (see photo). To plane a surface on the jointer, first set the infeed table from '/:o in. lo '/s in. below the cutterhead knives lo prov ide the desired depth of cut. On the models 1 tested, you adjust cutting depth by twisting ihe infeed table adjustment knob located under the infeed table on ihe right-hand end of the machine. You then pass the workpiece over the revolving cutterhead. holding it securely against by Jim Barrel! ness planers for planing slock to a precise- thickness. On ihe other hand, it's easier lo flatten a cupped, warped, or twisted board on the jointer. For this reason, most woodworkers use jointers primarily for edge-planing operations. If the boards are narrow enough for face planing, you can also use ihe jointer to true boards—thai is, create four smooth surfaces that are exactly 90 degrees to each other. To do this. ANW<5MY the fence. The cutterhead guard automatical ly retracts as you feed Ihe slock through the machine, then springs back once the wood has passed through. The fence can be tilled up to 45 degrees for bevel and chamfer cuts (see photo). Several manufacturers refer lo their machines as jointer-planers, typically because the operation of smoothing the edge of a board is called jointing, w hile smoothing the face of the board is called planing. How ever, the w idth of boards a jointer can "plane"' is limited lo about 6 in. on most machines (as opposed to 10 in. or more on a thickness planer). Also, jointers aren't nearly as good as thick- run one edge of the stock through the jointer to make it straight and smooth: then place ibis edge against the jointer fence, and plane one adjacent face of the board. Next, square the opposite edge of the board by running the board through the table saw. with the jointed edge against the fence and the planed face Hal against the saw table. This makes ihe opposite edge parallel to Ihe first. From there, you can remove ihe saw marks by running the cul edge through the jointer, then plane the opposite face of the board by running it ihrough a thickness planer (surfacer). to achieve a uniform thickness. My explanation of the procedure is The Woodworker's Jounul |