Woodworker's Journal 1994-18-1, страница 64

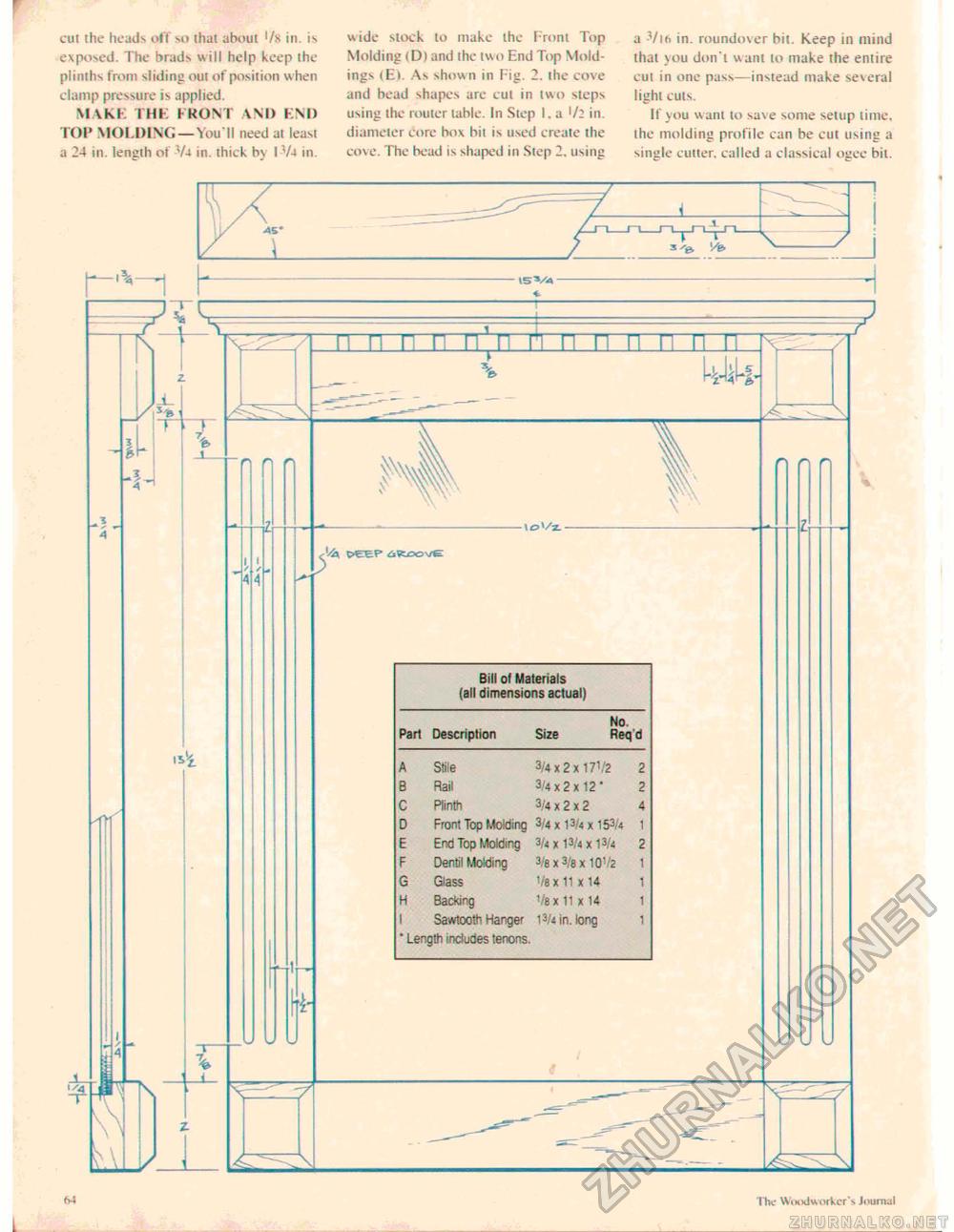

cui the heads oft mi that about '/s in. is exposed. The brads w ill help keep the plinths from sliding out of position w hen clump pressure is applied. MAKE THE FRONT AND KM) TOP MOLDING—You'll need at least a 24 in. length of V-t in. thick by I Vj in. wide stock to make the Front Top Molding <D) and the tw o End Top Moldings (E). As show n in Fig. 2. the cove and bead shapes are cut in two steps using the router table. In Step I. a '/2 in. diameter core box hit is used create the cove. The bead is shaped in Step 2. using a Vi6 in, roundover bit. Keep in mind that you don't w ant lo make the entire cut in one pass—instead make several light cuts. If you wanl lo sav e some setup lime, the molding profile can be cul using a single cutter, called a classical ogee bit. b % Irh \\ ^ A J ii fi n ii ii"n n n n n n n r % ■lo'/z. - PEEP iMtoove

X .">8 The Woodworker's Journal |

||||||||||||||||||||||||||||||||||||||||||