Woodworker's Journal 1994-18-1, страница 68

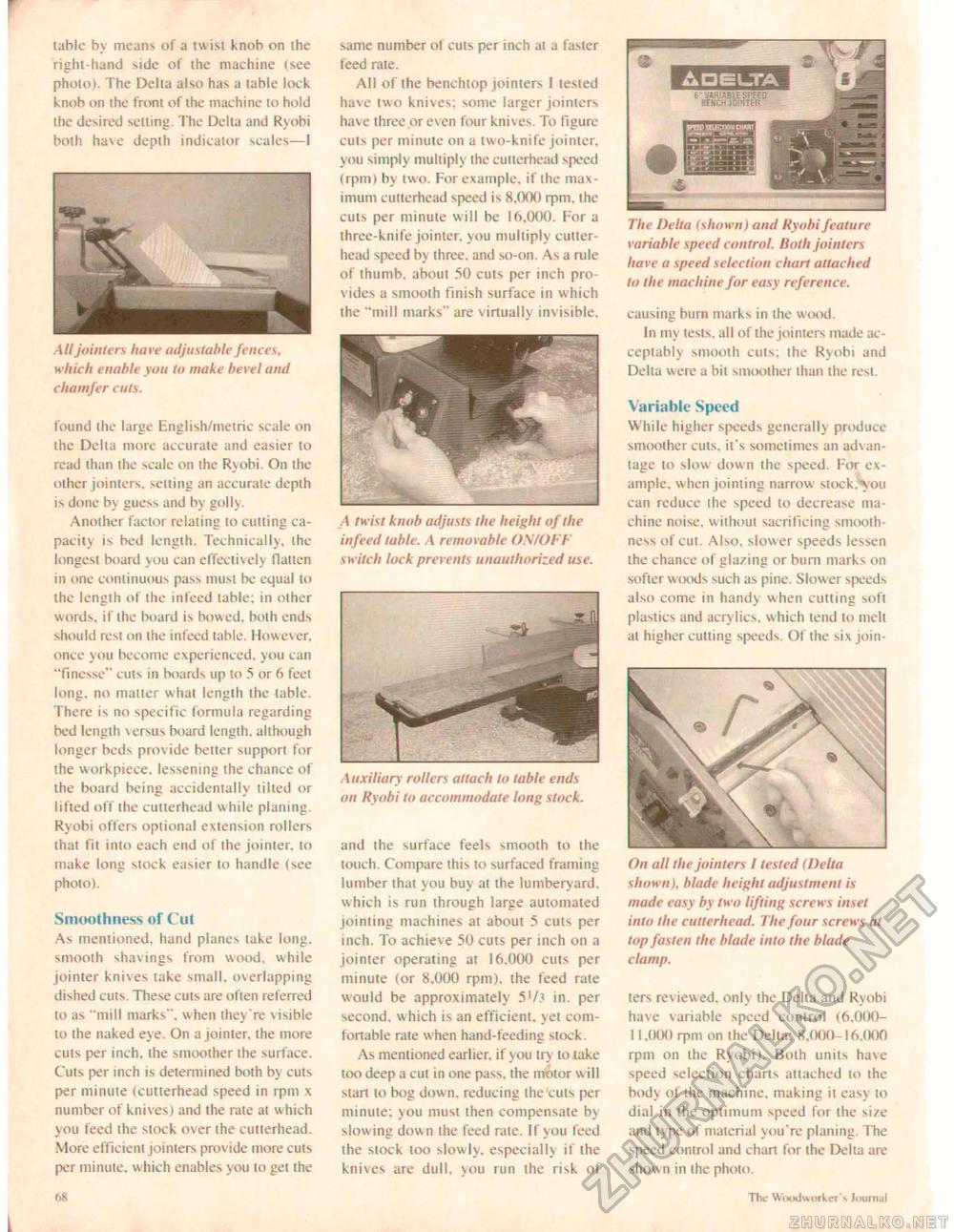

r lahlc hv means of a tw isl knob on ihe right-hand side of ihe machine (see phoio). The DeUa also has a lable lock knob on ihe front of ihe machine to hold ihe desired selling. The Delta and Ryobi both have depth indicator scales—I Alt jointers have adjustable fences, which enable you to make bevel and chamfer cuts. found the large English/metric scale on ihe Delia more accurate and easier to read than the scale on the Ryobi. On the other jointers, selling an accurate depth is done by guess and by golly. Another factor relating to cutting capacity is bed length. Technically, the longest board you can effectively flatten in one continuous pass must be equal to ihe length of ihe infeed lable; in other words, if ihe board is bowed, both ends should rest on ihe infeed table. However, once you become experienced, you can "finesse" cuts in boards up to 5 or 6 feel long, no mailer what length the table. There is no specific formula regarding bed length versus board length, although longer beds provide better support for the workpiece. lessening the chance of ihe board being accidentally tilted or lifted off the cutterhead while planing. Ryobi offers optional extension rollers lhat fit into each end of the jointer, to make long stock easier to handle (see photo). Smoothness of Cul As mentioned, hand planes take long, smooth shavings from wood, while jointer knives take small, overlapping dished cuts. These cuts are often referred to as "mill marks", when they're visible to the naked eye. On a jointer, the more cuis per inch, the smoother the surface. Cuts per inch is determined both by culs per minute (cutterhead speed in rpm x number of knives) and the rate ai which you feed the stock over the cullerhead. More efficient jointers provide more cuts per minute, which enables you lo get ihe same number of culs per inch at a faster feed rate. All of ihe henchtop jointers I tested have two knives; some larger jointers have three or even four knives. To figure cuts per minute on a two-knife jointer, you simply multiply the cutterhead speed (rpm) by two. For example, if the maximum cullerhead speed is 8,000 rpm, the cuts per minute will be 16,000. For a three-knife jointer, you multiply cutterhead speed by three, and so-on. As a rule of thumb, about 50 cuts per inch provides a smooth finish surface in which the "mill marks" are virtually invisible. A twist knob adjusts the height of the infeed table. A removable OS/OFF switch lock prevents unauthorized use. Auxiliary rollers attach to table ends on Ryobi to accommodate long stock. and the surface feels smooth to ihe touch. Compare this to surfaced framing lumber that you buy at the lumberyard, which is run through large automated jointing machines at about 5 cuts per inch. To achieve 50 cuts per inch on a jointer operating at 16,000 cuts per minuie (or 8.000 rpm). the feed rate would be approximately 51/? in. per second, which is an efficient, yet comfortable rale when hand-feeding stock. As mentioned earlier, if y ou try to take too deep a cut in one pass, the motor w ill start to bog down, reducing the cuts per minute: you must then compensate by slowing down the feed rale. If you feed the stock too slowly, especially if ihe knives are dull, you run ihe risk of The Delta (shown) and Ryobi feature variable speed control, liotli jointers have a speed selection chart attached to the machine for easy reference. causing hum marks in the wood. In my tests, all of the jointers made acceptably smooth cuts; the Ryobi and Delta were a bit smoother than the rest. Variable Speed While higher speeds generally produce smoother cuts, ii's sometimes an advantage to slow down the speed. For example, w hen jointing narrow stock/vou can reduce the speed lo decrease machine noise, without sacrificing smoothness of cut. Also, slower speeds lessen the chance of glazing or burn marks on softer woods such as pine. Slow er speeds also come in handy when cutting soft plastics and acrylics, which tend lo mell al higher cutting speeds. Of the six join- On all the jointers / tested (Delta shown), blade height adjustment is made easy by two lifting screws inset into the cullerhead. The four screws at top fasten flic blade into the blade clamp. ters reviewed, only the Delia and Ryobi have variable speed control (6.00011.000 rpm on the Delta; 8,000-16,000 rpm on the Ryobi). Both units have speed selection charts attached to the body of the machine, making it easy to dial in ihe optimum speed for ihe size and type of material you're planing. The speed control and charl for ihe Delia are show n in ihe photo. .">8 The Woodworker's Journal |