Woodworker's Journal 1994-18-2, страница 12

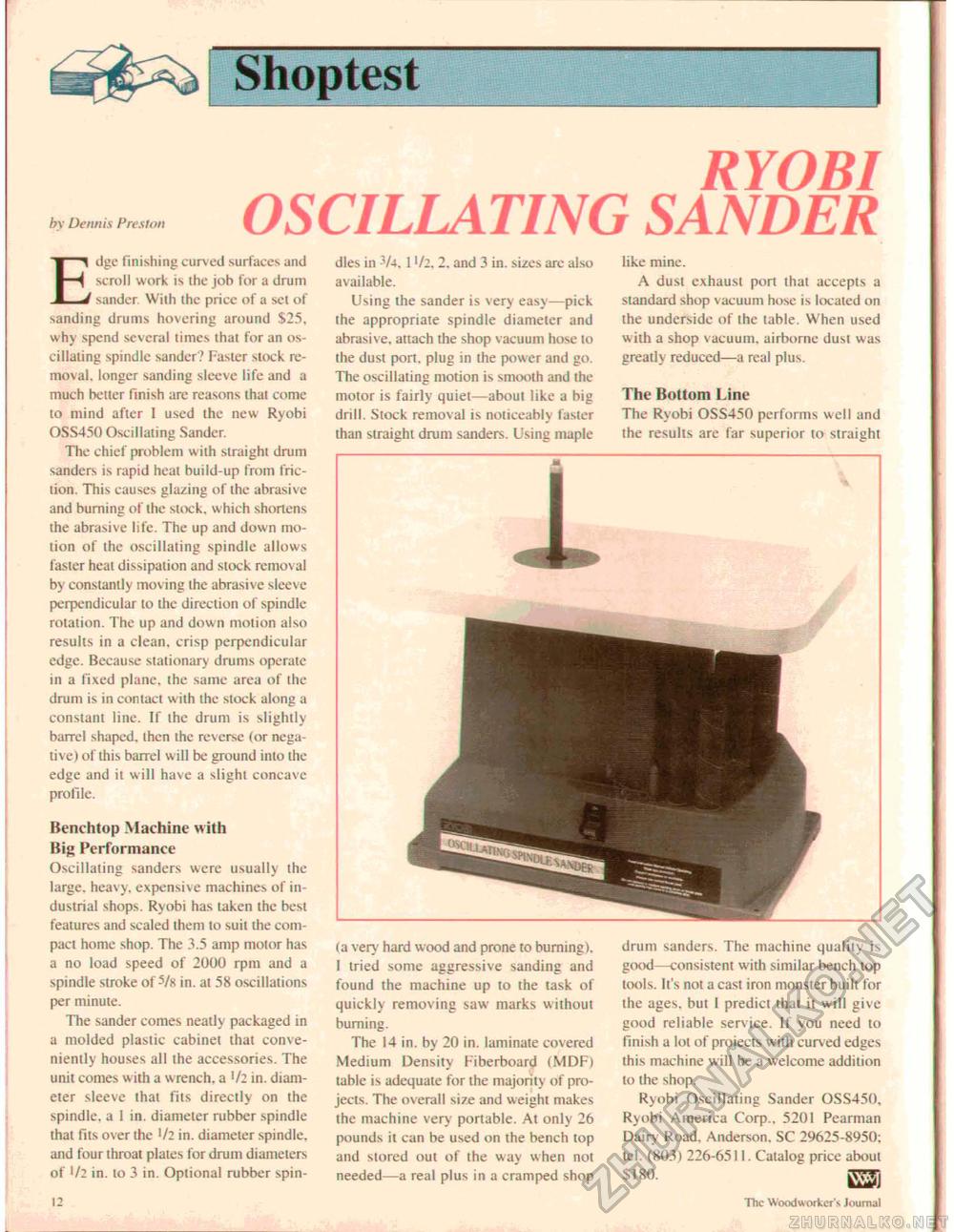

fry Dennis Preston RYOB1 OSCILLATING SANDER Edge finishing curved surfaces and scroll work is the job for a drum sander. With the price of a set of sanding drums hovering around $25, why spend several times that for an oscillating spindle sander? Faster slock removal. longer sanding sleeve life and a much better finish are reasons thai come lo mind after I used the new Ryobi OSS45G Oscillating Sander. The chief problem w ith straight drum sanders is rapid heat build-up from friction. This causes glazing of the abrasive and burning of the stock, which shortens the abrasive life. The up and down motion of the oscillating spindle allows faster heat dissipation and slock removal by constantly moving ihe abrasive sleeve perpendicular to the direction of spindle rotation. The up and down motion also results in a clean, crisp perpendicular edge. Because stationary drums operate in a fixed plane, the same area of the drum is in contact with the stock along a constant line. If the drum is slightly barrel shaped, then the reverse for negative) of this barrel will be ground into the edge and it will have a slight concave profile. Benchtop Machine with Big Performance Oscillating sanders were usually the large, heavy, expensive machines of industrial shops. Ryobi has taken the best features and scaled them lo suit the compact home shop. The 3.5 amp motor has a no load speed of 2000 rpm and a spindle stroke of 5/8 in. at 58 oscillations per minute. The sander comes neatly packaged in a molded plastic cabinet that conveniently houses all the accessories. The unit comes w ith a wrench, a '/2 in. diameter sleeve that fits directly on the spindle, a 1 in. diameter rubber spindle that fits over the '/2 in. diameter spindle, and four throat plates for drum diameters of 1/2 in. lo 3 in. Optional rubber spin- 12 dies in -V4, 1 '/2, 2. and 3 in. sizes arc also available. Using the sander is very easy—pick the appropriate spindle diameter and abrasive, attach the shop vacuum hose lo ihe dust porl, plug in the power and go. The oscillating motion is smooth and the motor is fairly quiet—about like a big drill. Stock removal is noticeably faster than straight drum sanders. Using maple like mine. A dust exhaust port that accepts a standard shop vacuum hose is located on the underside of the table. When used with a shop vacuum, airborne dust was greatly reduced—-a real plus. The Bottom Line The Ryobi 05S450 performs well and the results are far superior to straight (a very hard wood and prone to burning), I tried some aggressive sanding and found the machine up to the task of quickly removing saw marks without burning. The 14 in. by 20 in. laminate covered Medium Density Fiberboard (MDF) tabic is adequate for the majority of projects. The overall size and weight makes the machine very portable. At only 26 pounds it can be used on the bench top and stored out of the way when not needed—a real plus in a cramped shop drum sanders. The machine quality is good—consistent with similar bench top tools. It's not a cast iron monster built for ihe ages, but I predict that it will give good reliable service. If you need to finish a lot of projects with curved edges this machine will be a welcome addition to the shop. Ryobi Oscillating Sander 05S450. Ryobi America Corp., 5201 Pearman Dairy Road. Anderson, SC 29625-8950; tel. (803) 226-6511. Catalog price about SI 80. £2] t he Woodworker's Journal |