Woodworker's Journal 1994-18-2, страница 15

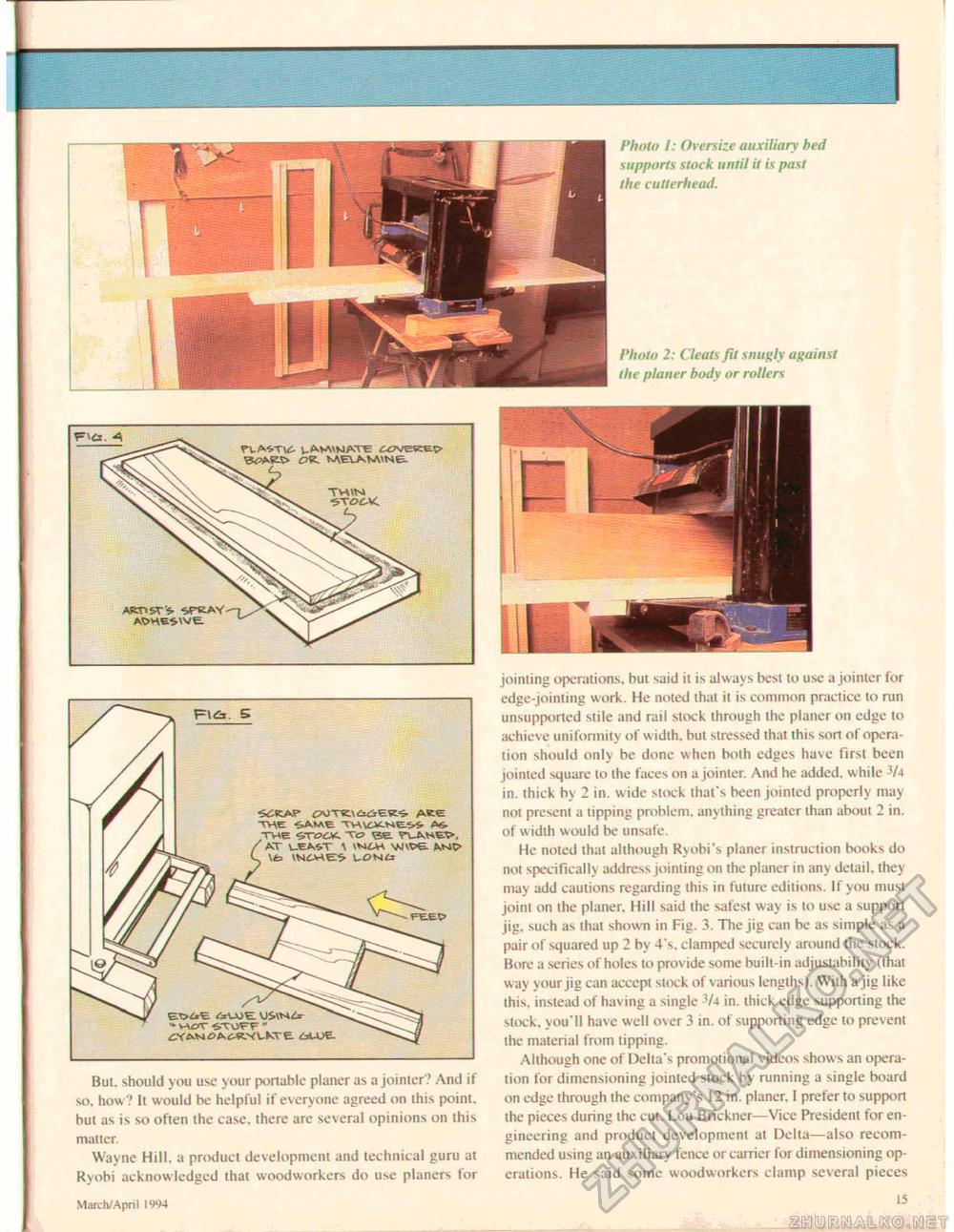

jointing operations, but said it is always best to use a jointer for edge-jointing work. He noted that it is common practice to run unsupported stile and rail stock through the planer on edge to achieve uniformity of width, but stressed that this sort of operation should only be done when both edges have first been jointed square to the faces on a jointer. And he added, while V-t in, thick by 2 in. w ide stock that's been jointed properly may not present a tipping problem, anything greater than about 2 in. of w idth would be unsafe. He noted that although Ryobi's planer instruction books do not specifically address jointing on the planer in any detail, they may add cautions regarding this in future editions. If you must joint on the planer. Hill said the safest way is to use a support jig, such as that shown in Fig. 3. The jig can be as simple as a pair of squared up 2 by 4's, clamped securely around the stock. Bore a series of holes to provide some built-in adjustability (that way your jig can accept stock of various lengths). With a jig like this, instead of having a single -V-i in. thick edge supporting the stock, you'll have well over 3 in. of supporting edge to prevent the material from lipping. Although one of Delta's promotional videos shows an operation for dimensioning jointed stock by running a single board on edge through the company's 12 in. planer. I prefer to support the pieces during the cut. Lou Brickner—Vice President for engineering and product development al Delta—also recommended using an auxiliary fence or carrier for dimensioning operations. He said some woodworkers clamp several pieces But. should you use your portable planer as a jointer? And if so. how? It would be helpful if everyone agreed on this point, but as is so often the case, there arc several opinions on this matter, Wayne Hill, a product development and technical guru at Ryobi acknowledged that woodworkers do use planers for March/April IW4 15 |