Woodworker's Journal 1994-18-2, страница 17

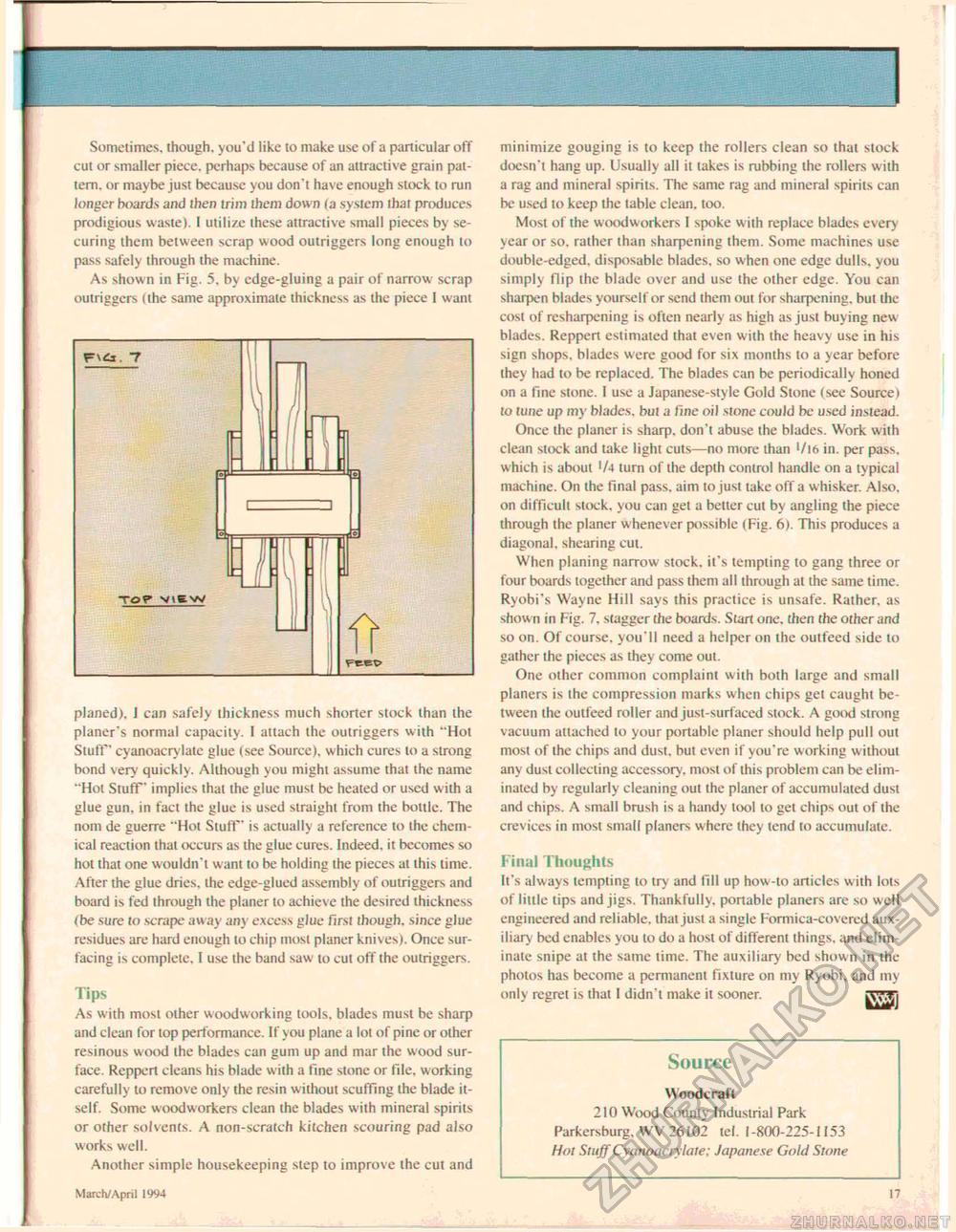

Sometimes, though, you'd like to make use of a particular off cut or smaller piece, perhaps because of an attractive grain pattern. or maybe just because you don't have enough stock to run longer boards and then trim them down (a system that produces prodigious waste). I utilize these attractive small pieces by securing them between scrap wood outriggers long enough to pass safely through the machine. As shown in Fig. 5. by edge-gluing a pair of narrow scrap outriggers ( the same approximate thickness as the piece I want planed). J can safely thickness much shorter stock than the planer's normal capacity. I attach the outriggers with ' Hot Stuff' cyanoacrylate glue (see Source), which cures to a strong bond very quickly. Although you might assume that the name "Hot Stuff' implies that the glue must be heated or used with a glue gun. in fact the glue is used straight from the bottle. The nom de guerre "Hot Stuff' is actually a reference to the chemical reaction that occurs as the glue cures. Indeed, it becomes so hot that one wouldn't want to be holding the pieces at this time. After the glue dries, the edge-glued assembly of outriggers and board is fed through the planer to achieve the desired thickness (be sure to scrape away any excess glue first though, since glue residues are hard enough to chip most planer knives). Once surfacing is complete. I use the band saw to cut off the outriggers. Tips As with most other woodworking tools, blades must be sharp and clean for top performance. If you plane a lot of pine or other resinous wood the blades can gum up and mar the wood surface. Reppert cleans his blade with a fine stone or file, working carefully to remove only the resin without scuffing the blade itself. Some woodworkers clean the blades with mineral spirits or other solvents. A non-scratch kitchen scouring pad also works well. Another simple housekeeping step to improve the cut and minimize gouging is to keep the rollers clean so that stock doesn't hang up. Usually all it lakes is rubbing the rollers with a rag and mineral spirits. The same rag and mineral spirits can be used to keep the table clean, too. Most of the woodworkers I spoke with replace blades every year or so. rather than sharpening them. Some machines use double-edged, disposable blades, so when one edge dulls, you simply flip the blade over and use the other edge. You can sharpen blades yourself or send them out for sharpening, but the cost of resharpening is often nearly as high as just buying new blades. Reppert estimated that even with the heavy use in his sign shops, blades were good for six months to a year before they had to be replaced. The blades can be periodically honed on a fine stone. I use a Japanese-style Gold Stone (see Source) to tune up my blades, but a fine oil .stone could be used instead. Once the planer is sharp, don't abuse the blades. Work with clean stock and take light cuts—no more than l/i6 in. per pass, which is about '/4 turn of the depth control handle on a ty pical machine. On the final pass, aim to just take off a w hisker. Also, on difficult slock, you can get a better cut by angling the piece through the planer whenever possible (Fig. 6). This produces a diagonal, shearing cut. When planing narrow stock, it's tempting to gang three or four boards together and pass them all through al the same time. Ryobi's Wayne Hill says this practice is unsafe. Rather, as shown in Fig. 7. stagger the boards. Start one. then the other and so on. Of course, you'll need a helper on the outfeed side to gather the pieces as they come out. One other common complaint with both large and small planers is ihe compression marks when chips get caught between the outleed roller and just-surfaced stock. A good strong vacuum attached to your portable planer should help pull out most of the chips and dust, but even if you're working w ithout any dust collecting accessory, most of this problem can be eliminated by regularly cleaning out the planer of accumulated dust and chips. A small brush is a handy tool lo get chips out of the crevices in most small planers where they tend to accumulate. Final Thoughts It's always tempting to try and fill up how-to articles with lots of little tips and jigs. Thankfully, portable planers are so well engineered and reliable, that just a single Formica-covered auxiliary bed enables you to do a hosi of different things, and eliminate snipe at the same lime. The auxiliary bed shown in the photos has become a permanent fixture on my Ryobi, and my only regret is that I didn't make it sooner. F\2Tl Source Woodcraft 210 Wood County Industrial Park Parkersburg. WV 26102 tel. I -800-225-1153 Hoi Stuff Cyanoacrylate; Japanese Gold Stone FT TO? VIEW fr March/ April 1994 17 |