Woodworker's Journal 1994-18-2, страница 20

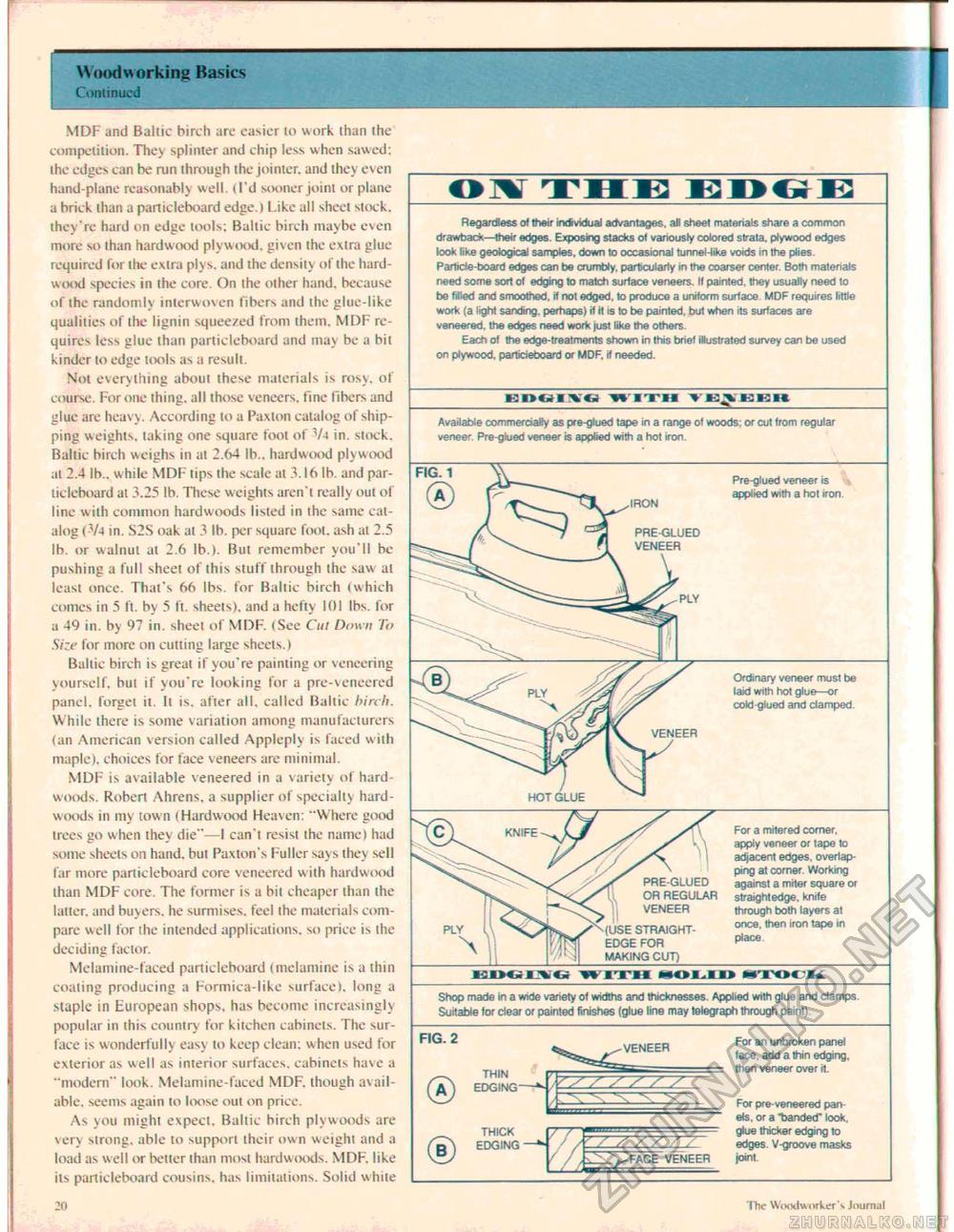

Woodworking Basics Continued MDF and Baltic birch are easier to work than the competition. They splinter and chip less when sawed: the edges can be run through the jointer, and they even hand-plane reasonably well. (I'd sooner joint or plane a hrick than a particleboard edge.) Like all sheet stock, they're hard on edge tools; Baltic birch maybe even more so than hardwood plywixid. given the extra glue required for the extra plys, and the density of the hard-wotxl species in the core. On the other hand, because of the randomly interwoven libers and the glue-like qualities of the lignin squeezed from them. MDF requires less glue than particleboard and may be a bit kinder to edge tools as a result. Not everything about these materials is rosy, of course. For one thing, all those veneers, tine libers and glue are heavy. According to a Paxlon catalog of shipping weights, taking one square foot of V4 in. stock. Baltic birch weighs in at 2.64 lb., hardwood plywood at 2.4 lb., while MDF tips the scale at 3.1ft lb. and par-Licleboard at 3.25 lb. These weights aren't really out of line with common hardwoods listed in the same catalog (Vj in. S2S oak at 3 lb. per square fool, ash at 2.5 lb. or walnut ai 2.6 lb.>. But remember you'll be pushing a full sheet of this stuff through the saw al least once. That's 66 lbs. for Baltic birch (which comes in 5 ft. by 5 ft. sheets), and a hefty 101 lbs. for a 49 in. by 97 in. sheet of MDF. (See Cut Down To Size for more on cutting large sheets.) Baltic birch is great if you're painting or veneering yourself, but if you're looking for a pre-veneered panel, forget it. It is. afier all, called Baltic birch. While there is some variation among manufacturers (an American version called Appleply is faced with maple), choices for face veneers are minimal. MDF is available veneered in a variety of hard w oods. Robert Ahrens, a supplier of specialty hardwoods in my town (Hardwood Heaven: "Where good trees go when they die"—I can't resist ihe name) had some sheets on hand, but Paxton's Fuller savs they sell far more particleboard core veneered w ith hardwood than MDF core. The former is a bil cheaper than (he latter, and buyers, he surmises, feel the materials compare well for the intended applications, so price is the deciding factor. Melamine-faced particleboard (melamine is a thin coaling producing a Formica-like surface). long a staple in European shops, has become increasingly popular in this country for kitchen cabinets. The surface is wonderfully easy to keep clean: when used for exterior as well as interior surfaces, cabinets have a "modern" look. Melamine-faced MDF. though available. seems again to loose out on price. As you might expect. Baltic birch plywoods are very strong, able to support their own weight and a load as well or better than most hardwoods. MDF. like its particleboard cousins, has limitations. Solid white OMT THE EDGE Regardless of their individual advantages, all sheet materials share a common drawback—their edges. Exposing stacks of variously colored strata, plywood edges look like geological samples, down to occasional tunnel-like voids in the plies. Panicle-board edges can be crumbly, particularly in the coarser center, Both matenals need some sort of edging to match surface veneers. If painted, they usually need to be filled and smoothed, if not edged, to produce a uniform surface MDF requires litlle work (a light sanding, perhaps) it H is to be painted, but when its surfaces are veneered, the edges need work jusl like the others Each of the edge-treatments shown in this brief illustrated survey can be used on plywood, parbcieboard or MDF. if needed. Kn<»i \ «• ITll YE^KKH Available commercially as pre-giued tape in a range of woods: or cut from regular veneer. Pregiucd veneer is applied with a hot iron. FIG. 1 IRON PRE-GLUED VENEER Pre-glued veneer is applied with a hoi iron. Ordinary veneer must be laid with hoi glue—or CoW glued and clamped. PRE-GLUED OR REGULAR VENEER (USE STRAIGHTEDGE FOR MAKING CUT) For a milered comer, apply veneer or tape to adjacent edges, overlapping at corner. Working against a miter square or straightedge, knife through both layers at once, then iron tape in place. eoouiCi Shop made in a wide variety of widths and thicknesses. Applied with glue and clamps. Suitable for clear or painted finishes (glue line may telegraph through paint). FIG. 2 ® THIN EDGING- VENEER szzzzz THICK B ^ EDGING / / , IZTVFACT^VENEER _i_ For an unbroken panel face, add a thin edging, then veneer over it. For pre-veneered panels. or a "banded" look, glue thicker edging to edges V-groovB masks joint. 20 t he Woodworker's Journal |