Woodworker's Journal 1994-18-2, страница 21

oak. for example, will support more than six limes the weight of high-density particleboard and almost four times the weight of MDF before breaking. Problems are less likely lo arise in cabinet construction where the spans are supported or reinforced by partitions, face frames and so on. than in tablelops or shelving Veneered MDF or particleboard is, of course, stronger than their unveneered versions. Price No matter how many qualitative comparisons can be made (and I'm sure there are many more than ! ve lisled), eventually we all come lo price. Below is a comparison taken from the current Paxton Lumber catalog. All sheets are -V-4 in.. 4 ft. by 8 ft. unless oth erwise specified. Prices arc for an order of I to 9 sheets (exclusive of shipping); larger quantities arc cheaper. Because of differences in si/e between Baltic birch and the others, price per square foot is provided You're likely to pay more from a local supplier, and there will be. of course, regional and local price varia

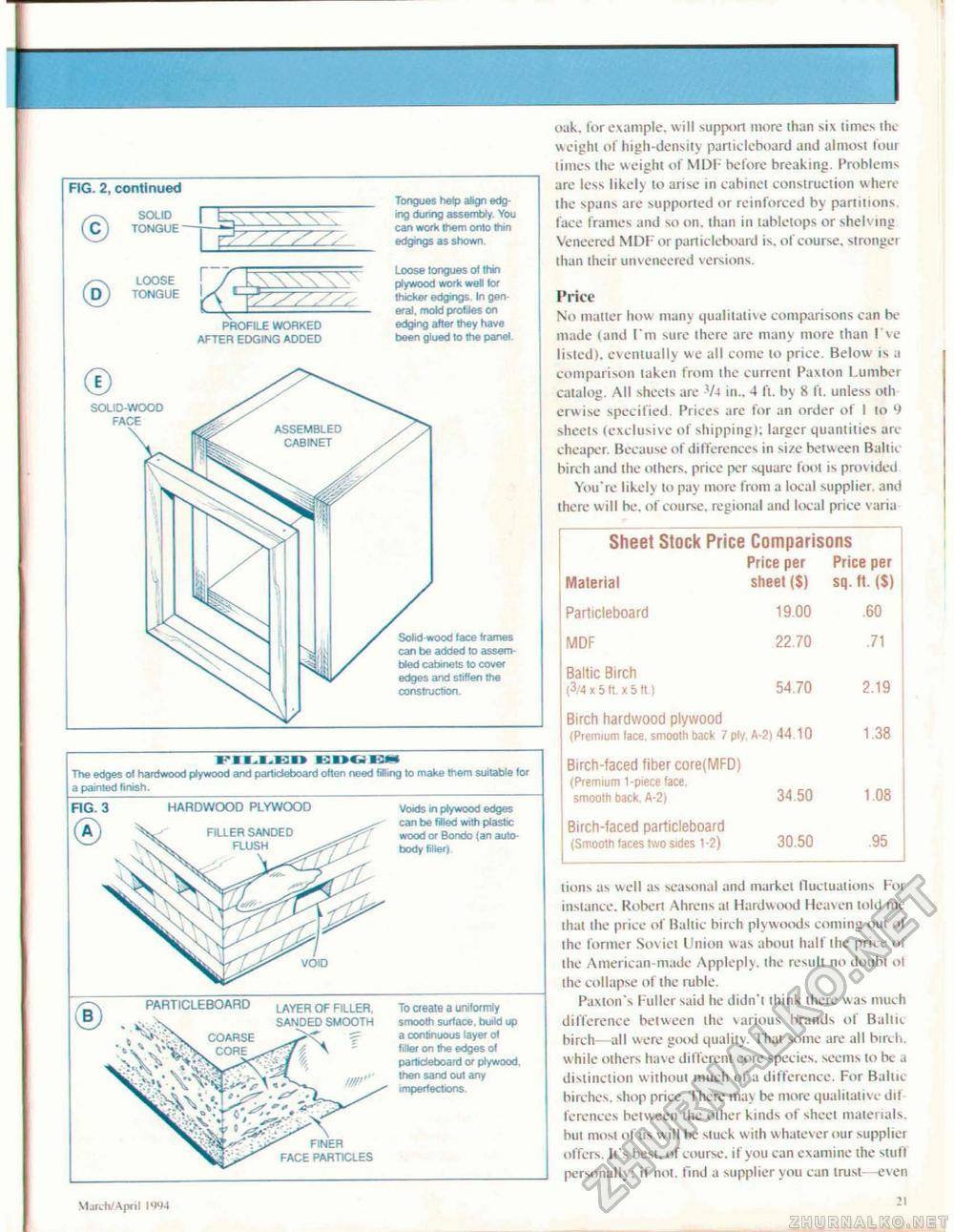

lions as well as seasonal and market fluctuations For instance. Robert Ahrens al Hardwood Heaven lold me that the price of Baltic birch plywoods coming out ol the former Soviet Union was about half the price ol the American-made Appleply. the result no doubt ot the collapse of the ruble. Paxton's Fuller said he didn't think there was much difference between the various brands of Baliic birch—all were good quality. That some are all birch, w hile others have different core species, seems to be a distinction without much of a difference. For Baltic birches, shop price. There may be more qualitative dil fcrences between the other kinds of sheet materials, but most of us w ill be siuck with w hatever our supplier offers. It's best, of course, if you can examine the stuff personally: if not. find a supplier you can trust—even PII.I.KIt KIH.BH The edges ot hardwood plywood and particleboard often need tilling to make Ihem suitable lor a painted finish. _ FIG. 3 HARDWOOD PLYWOOD Voids in plywood edges can be Idled with plastic wood or Bondo (an auto-body filter). FINER FACE PARTICLES PARTICLEBOARD To create a uniformly smooth surface, build up a continuous layer of Tiller on the edges of particteboard or plywood, then sand out any imperfections. LAYER OF FILLER. SANDED SMOOTH March/April l'*>4 II |

|||||||||||||||||||||||||||||||||||||