Woodworker's Journal 1994-18-2, страница 19

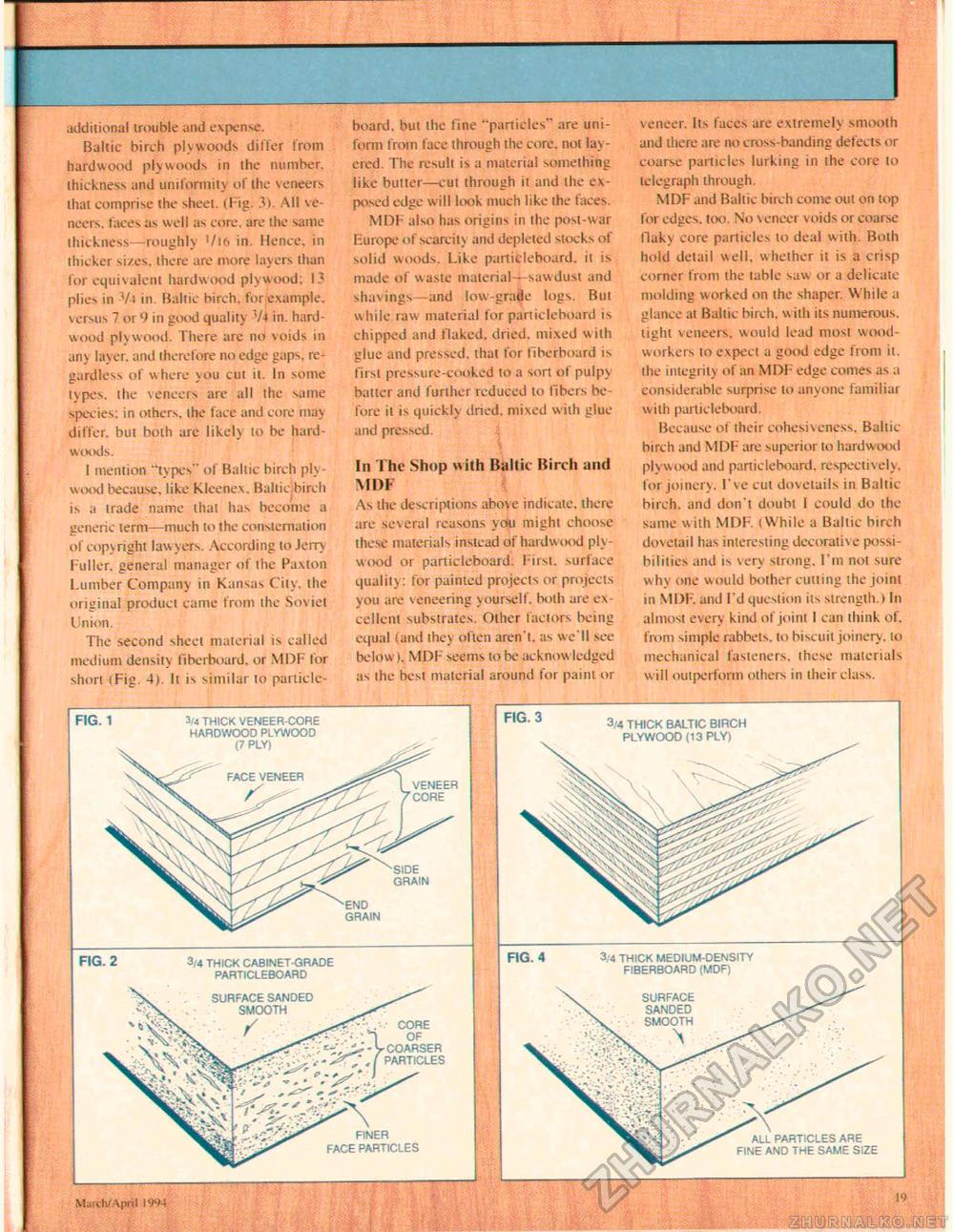

additional trouble and expense. Baltic birch plywoods differ from bard wood plywoods in the number, thickness and uniformity of the veneers that comprise the sheet, (Fig. 3). All veneers, faces as well as core, are the same thickness—roughly '/if? in. Hence, in thicker sizes, there are more layers than for equivalent hardwood plywood: 13 plies in Vt in. Baltic birch, for example, versus 7 or 9 in good quality V-t in. hardwood plywood. There are no voids in any layer, and therefore no edge gups, regardless of where you cut it. In some types, the veneers are all the same species; in others, the face and core may differ, but both are likely to be hardwoods. 1 mention "ty pes'" of Baltic birch ply wood because, like Kleenex, Balticjbireh is a trade name that has become a generic term—much to the consternation of copyright lawyers. According to Jerry Fuller, general manager of the Paxton Lumber Company in Kansas City , the original product came from the Soviet Union. The second sheet material is called medium density fibcrboard. or MDF for short (Fig. -I) It is similar to particle board. but the fine "particles" are uniform from face through the core, not lay ered. The result is a material something like butter—cut through it and the exposed edge w ill look much like the faces. MDF also has origins in the post-war Europe of scarcity and depleted stocks ot solid woods. Like particleboard. it is made of waste material—sawdust and shavings -and low-grade logs. But while raw material for particleboard is chipped and flaked, dried, mixed w ith glue and pressed, that for fibcrboard is first pressure-cooked to a sort of pulpy baiter and further reduced to fibers before it is quickly dried, mixed with glue and pressed. In I he Shop with Baltic Birch and MDF As the descriptions above indicate, there are several reasons yesu might choose these materials instead of hardwood plywood or particleboard. first, surface quality: for painted projects or projects you are veneering yourself, both are ev cellenl substrates. Other factors being equal (and they often aren't, as we'll see below). MDF seems to be acknow ledged as the best material around for paint or veneer. Its faces are extremely smooth and there are no cross-banding defects or coarse particles lurking in the core lo telegraph through. MDF and Baltic birch come out on top for edges, too. No veneer voids or coarse llakv core particles to deal w ith. Both hold detail well, whether it is a crisp corner from the table saw or a delicate molding worked on the shaper. While a glance at Baltic birch, w ith its numerous, tight veneers, would lead most woodworkers to expect a good edge from it, the integrity of an MDF edge comes as a considerable surprise lo anyone familiar with particleboard. Because of their cohesivcncss. Baltic birch and MDF are superior lo hardwood plywood and particleboard. respectively, for joinery. I've cut dovetails in Baltic birch, and don't doubt 1 could do the same with MDF. (While a Baltic birch dovetail has interesting decorative possibilities and is very strong, I'm not sure why one would bother cutting ihe joint m MDF. and I'd question its strength.) In almost every kind of joint 1 can think of, from simple rabbets, to biscuit joinery, to mechanical fasteners, these materials w ill outperform others in their class. FIG. 3 3/4 thick baltic birch plywood i'13 ply) all particles are fine and the same size FIG. 2 3/4 THICK CABINET-GRADE PARTICLEBOARD core of ■coarser particles finer face particles _I FIG. 4 3/4 thick medium-density f5ber80ard (mdf) FIG. 1 thick veneer-core hardwood plywood grain veneer core Milrch/Aptfl I994 19 |