Woodworker's Journal 1994-18-2, страница 23

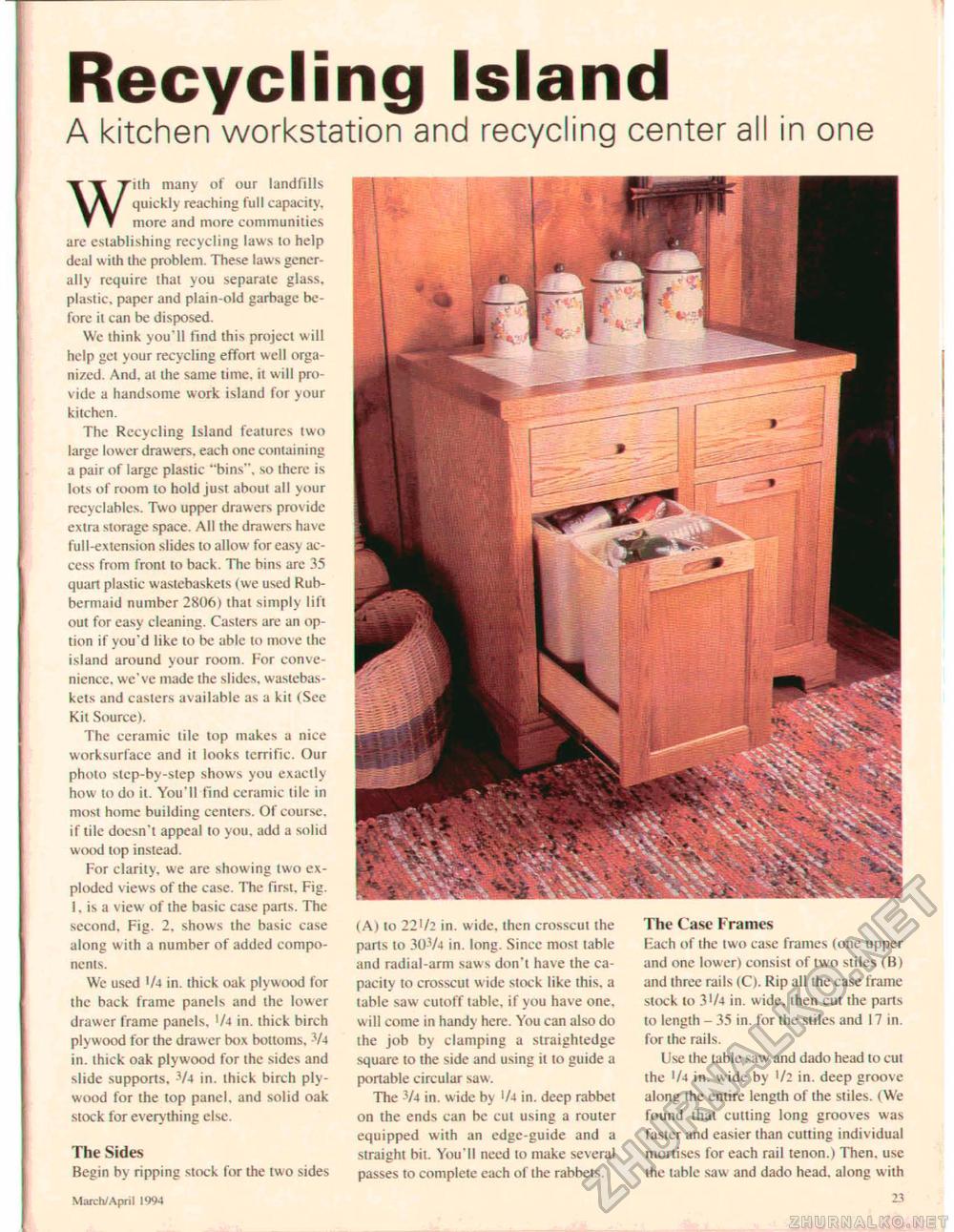

Recycling Island A kitchen workstation and recycling center all in one With many of our landfills quickly reaching full capacity, more and more communities are establishing recycling laws to help deal with the problem. These laws generally require thai you separate glass, plastic, paper and plain-old garbage before it can be disposed. Wc think you'll find this project will help get your recycling effort well organized. And, at the same time, ii will provide a handsome work island for your kitchen. The Recycling Island features two large lower drawers, each one containing a pair of large plastic "bins", so there is lots of room to hold just about all your recyclablcs. Two upper drawers provide extra storage space. All the drawers have l ull-extension slides to allow for easy access from front to back. The bins arc 35 quart plastic wastebaskets (we used Rubbermaid number 2806) that simply lift out for easy cleaning. Casters are an option if you'd like to be able to move the island around your room. For convenience, we've made (he slides, wastebaskets and casters available as a kit (See Kit Source). The ceramic tile top makes a nice worksurface and it looks tcrrific. Our photo stcp-by-step shows you exactly how lo do it. You'll find ceramic tile in most home building centers. Of course, if tile doesn't appeal to you. add a solid wood lop instead. For clarity, we are showing two exploded views of the case. The first. Fig. 1, is a view of the basic case parts. The second. Fig. 2, shows the basic case along w ith a number of added components. We used 'At in. thick oak plywood for the back frame panels and the lower drawer frame panels, '/4 in. thick birch plywood for the drawer box bottoms. V*i in. thick oak plywood for the sides and slide supports. 3/4 in. thick birch plywood for the top panel, and solid oak stock for everything else. The Sides Begin by ripping stock for the two sides (A) to 221/2 in, wide, then crosscut the parts lo 3G-V4 in. long. Since most table and radial-arm saw s don't have the capacity to crosscut w ide slock like this, a table saw cutoff table, if you have one. will come in handy here. You can also do the job by clamping a straightedge square to the side and using it to guide a portable circular saw. The 3/4 in. wide by '/4 in. deep rabbet on the ends can be cut using a router equipped with an edge-guide and a straight bit. You'll need to make several passes to complete each of the rabbets. The Case Frames Each of the two case frames (one upper and one lower) consist of two stiles (B) and three rails (C). Rip all the case frame stock to 31/4 in. wide, then cut the parts to length - 35 in. for the stiles and 17 in. for the rails. Use the table saw and dado head lo cut the '/4 in. wide by '/2 in. deep groove along the entire length of the stiles. (We found that cutting long grooves was faster and easier than cutting individual mortises for each rail tenon.) Then, use the table saw and dado head, along with March/April 1994 2.1 |