Woodworker's Journal 1994-18-2, страница 25

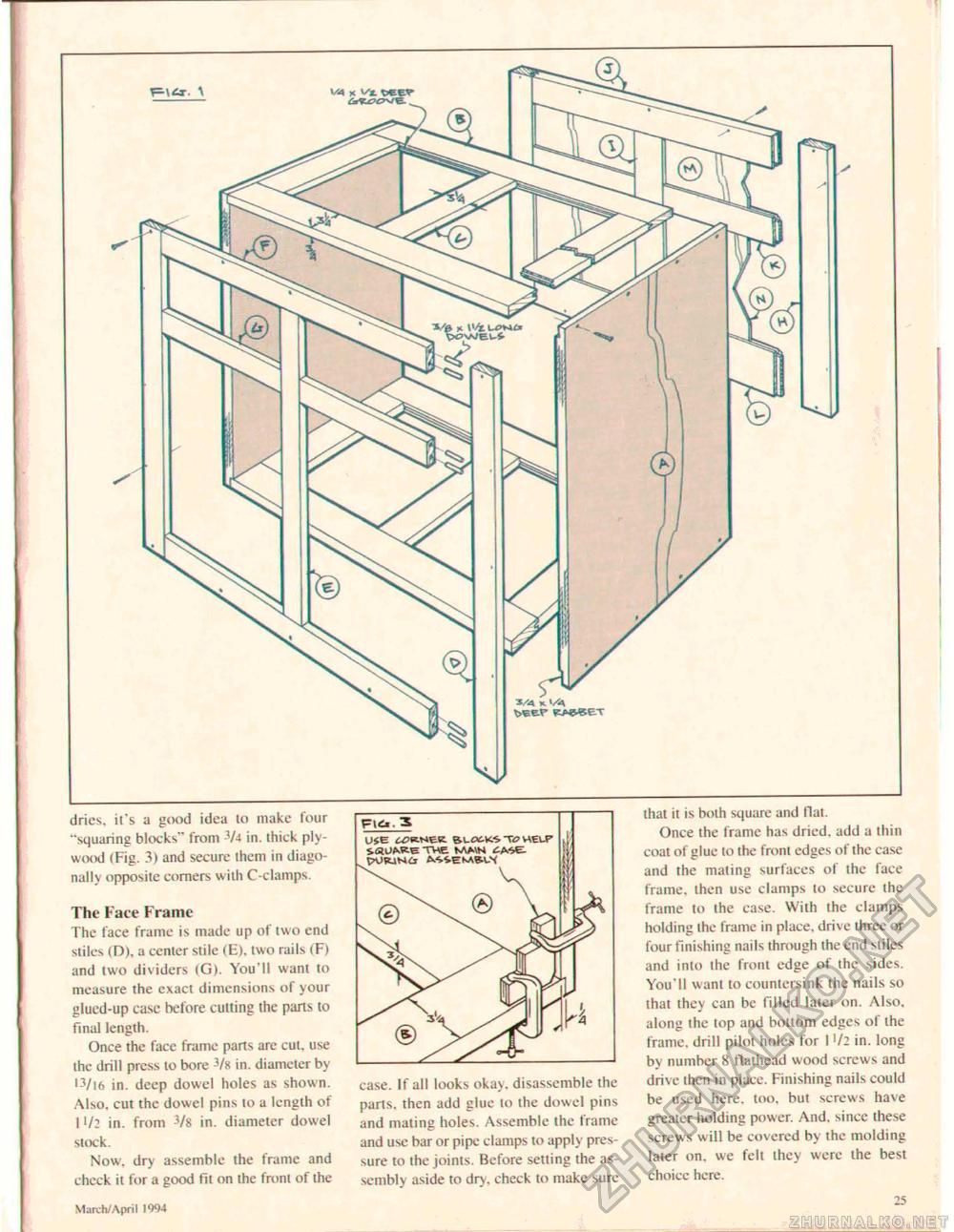

3/4 x beep wWET dries, it's a good idea lo make four "squaring blocks" from -V4 in. thick plywood (Fig. 3) and secure them in diagonally opposite corners with C-clamps. The Face Frame The face frame is made up of two end slilcs (D), a center stile (E). two rails (T) and two dividers (G). You'll want to measure the exact dimensions of your glucd-up case before cutting the pans to final length. Once the face frame parts are cut, use the drill press lo bore 3/« in. diameter by l3/lf> in. deep dowel holes as shown. Also, cut the dowel pins lo a length of IJ/2 in. from -Vs in. diameter dowel stock. Now. dry assemble the frame and check it for a good fit on the front of the Maich/April 1994 use tiW-NEK BLOCKS HELP S«L)Wte THE t>AMN Cp&E- case. If all looks okay, disassemble the parts, then add glue lo the dowel pins and mating holes. Assemble the frame and use bar or pipe clamps to apply pres sure to the joints. Before selling the assembly aside to dry . check to make sure that it is both square and Hat. Once the frame has dried, add a thin coat of glue to the front edges of the case and the mating surfaces of the face frame. Ihen use clamps to secure the frame to the case. With the clamps holding the frame in place, drive three or four finishing nails through the end stiles and into the front edge of the sides. You'll wanl lo countersink the nails so thai they can be filled later on. Also, along the top and bottom edges of the frame, drill pilot holes for I '/2 in. long by number 8 flathead wood screws and drive then in place. Finishing nails could be used here. too. but screws have greater holding power. And. since these screws will be covered by the molding later on. we fell they were the best choicc here. 25 |