Woodworker's Journal 1994-18-2, страница 13

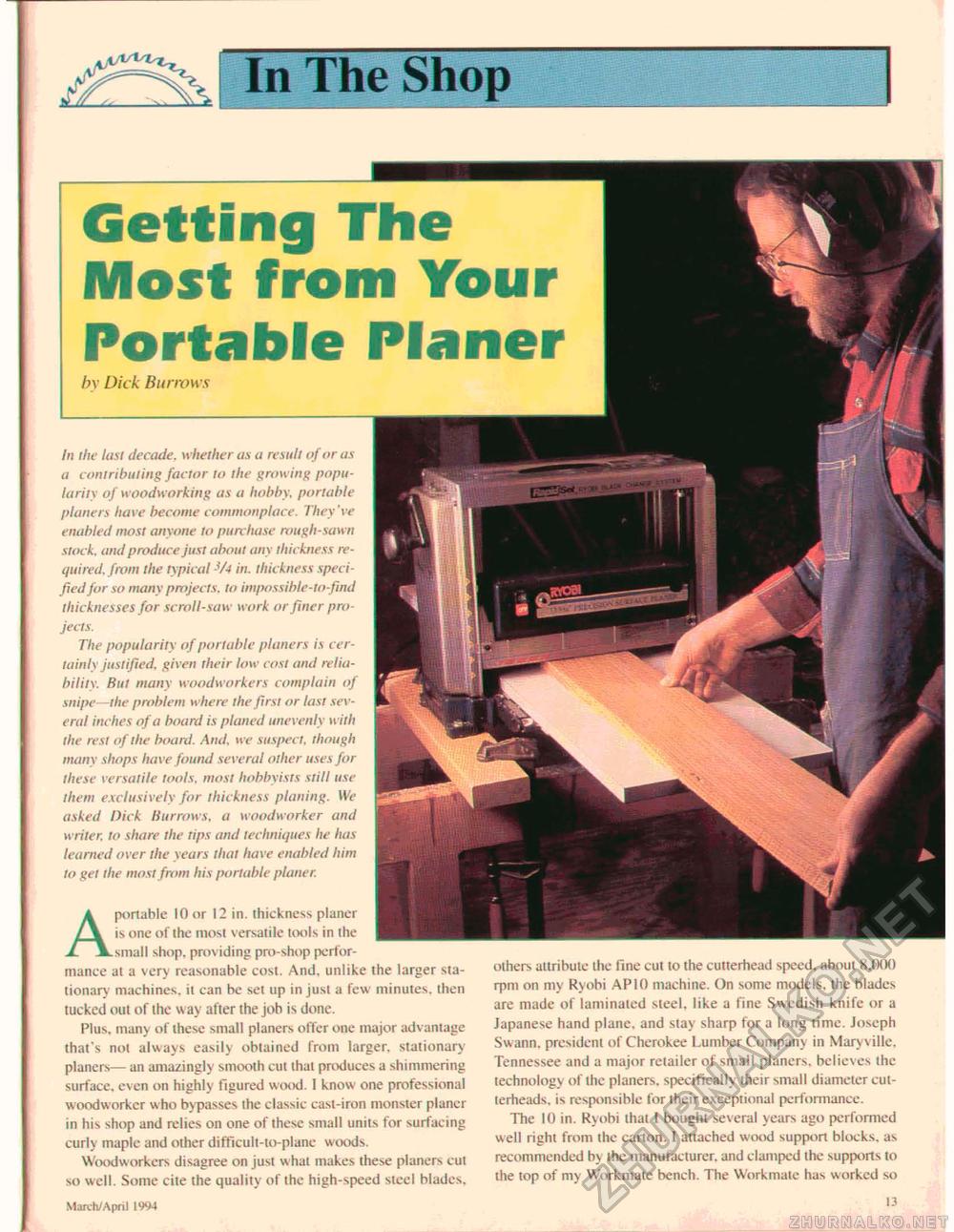

In The Shop • ^■■ '■■r-r . 'V / ... . - . fe ; M ___ Getting The Most from Your Portable Planer by Dick Burrows In the last decade, whether as a result of or as a contributing factor to the growing popularity of woodworking as a hobby, portable planers have become commonplace. They're enabled most anyone to purchase rough-sawn stock, and produce just about any thickness required, from ihe typical 3U in. thickness specified for so many projects, to impossible-to-find thicknesses for scroll-saw work or finer projects. The popularity of portable planers is certainly justified, given their low cost and reliability. Bui many woodworkers complain of snipe—the problem where the first or last several inches of a board is planed unevenly with the rest of the board. And. we suspect, though many shops have found several oilier uses for these versatile tools, most hobbyists still use them exclusively for thickness planing. Mr asked Dick Burrows, a woodworker and writer, to share the tips and techniques he has learned over the years that have enabled him lo get the most from his portable planer. others attribute the fine cut to the cutterhead speed, about 8,(XX) rpm on my Ryobi AP10 machine. On some models, the blades are made of laminated steel, like a fine Swedish knife or a Japanese hand plane, and stay sharp for a long time. Joseph Swann, president of Cherokee Lumber Company in Maryville. Tennessee and a major retailer of small planers, believes the technology of the planers, specifically their small diameter cut-terheads. is responsible for their exceptional performance. The 10 in. Ryobi that I bought several years ago performed well right from the carton. 1 attached wood support blocks, as recommended by the manufacturer, and damped the supports to the top of my Workmate bench. The Workmate has w orked so 13 A portable 10 or 12 in. thickness planer is one of the most versatile tools in the small shop, providing pro-shop performance at a very reasonable cost. And. unlike the larger stationary machines, it can be set up in just a few minutes, then tucked out of the way after the job is done. Plus, many of these small planers offer one major advantage that's not always easily obtained from larger, stationary planers— an amazingly smooth cut that produces a shimmering surface, even on highly figured wood. I know one professional woodworker who bypasses the classic cast-iron monster planer in his shop and relies on one of these small units for surfacing curly maple and other difficult-to-plane woods. Woodworkers disagree on just what makes these planers cut so well. Some cite the quality of the high-speed steel blades. March/ April 1994 |