Woodworker's Journal 1994-18-3, страница 43

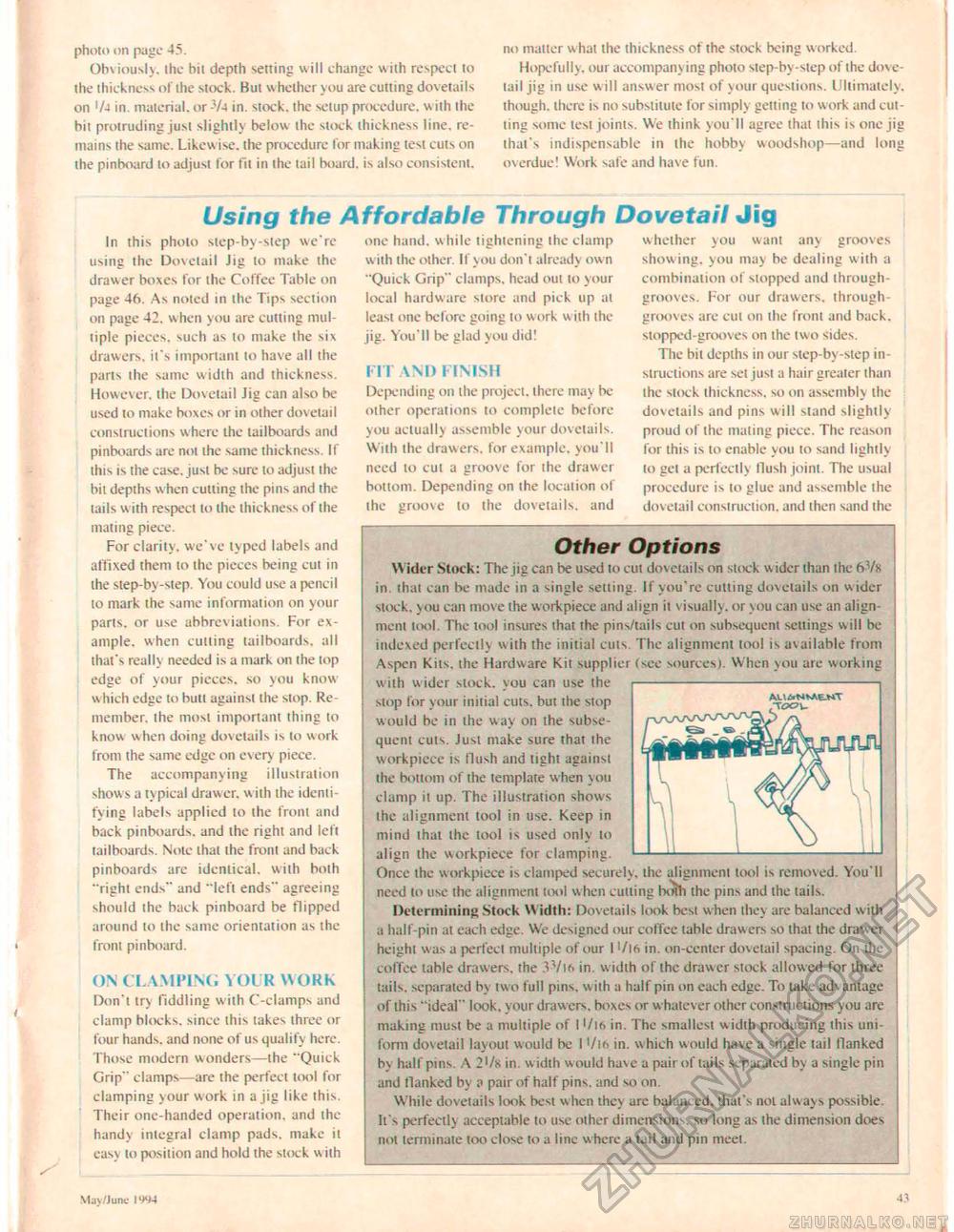

photo on page 45. Obviously, the bit depth setting will change with respect to the thickness of the stock. But w helhcr you are cutting dovetails on !/j in. material, or 3/4 in. stock, the setup procedure, w ith the bit protruding just slightly below the stock thickness line, remains the same. Likew ise, the procedure for making test cuts on the pinboard lo adjust for fit in the tail board, is also consistent. no matter whal the thickness of the stock being worked. Hopefully, our accompanying photo step-by-step of ihe dovetail jig in use will answer most of your questions. Ultimately, though, there is no substitute for simply getting lo work and cutting some test joints. We think vou'll agree thai this is one jig that's indispensable in the hobby woodshop—and long overdue! Work safe and have fun. Using the Affordable Through Dovetail Jig In this photo step-by-step we're using Ihe Dovetail Jig to make ihe drawer boxes for ihe Coffee Table on page 46. As noted in ihe Tips section on page 42. when you are cutting multiple pieces, such as to make the six drawers, it's important to have all the parts the same width and thickness. However, ihe Dovetail Jig can also be used to make boxes or in other dovetail constructions where the tailboards and pinboards arc not the same thickness. If ihis is the case, just be sure lo adjust the bit depths when culling the pins and the tails with respect to the thickness of the mating piece. For clarity, we've Ivped labels and affixed them to the pieces being cut in ihe step-by-step. You could use a pencil lo mark the same information on your parts, or use abbreviations. For example, when cutting tailboards, all that's really needed is a mark on the top edge of your pieces, so you know w hich edge to bull againsl ihe stop. Re member, the most important thing to know when doing dovetails is to work from the same edge on ev ery piece. The accompanying illustration shows a typical drawer, with the identifying labels applied to the front and back pinboards, and the right and left tailboards. Note thai the front and back pinboards arc identical, with both "right ends" and "left ends" agreeing should the back pinboard be flipped around lo the same orientation as the from pinboard. ON CLAMPING YOUR WORK Don't try fiddling with C-clamps and clamp blocks, since this takes ihree or four hands, and none of us qualify here. Those modern wonders—the "Quick Grip" clamps—are the perfect tool for clamping your w ork in a jig like this. Their one-handed operation, and the handy integral clamp pads, make it easv to position and hold the stock wiih one hand, w hile lightening ihe clamp with the other. If you don't already ow n "Quick Grip" clamps, head out to your local hardware store and pick up at least one before going to work with the jig. You'll be glad you did! FIT AND FINISH Depending on the project, there may be other operations to complete before you actually assemble your dovetails. With the drawers, for example, you'll need to cut a groove for the drawer bottom. Depending on the location of ihe groove to the dovetails, and whether you want any grooves show ing, you may be dealing with a combination of stopped and through-grooves. For our drawers, through-grooves are cut on the front and back, stopped-grooves on the two sides. The bit depths in our step-by-step instructions are set just a hair greater than the stock thickness, so on assembly the dovetails and pins will stand slightly proud of the mating piece. The reason for ihis is to enable you lo sand lightly lo get a perfectly flush joint. The usual procedure is to glue and assemble ihe dovetail construction, and then sand ihe Other Options Wider Stock: The jig can be used to cut dov etails on stock wider lhan the 67x in. that can be made in a single setting. If you're cutting dovetails on wider stock, you can move (he workpiece and align it visually, or you can use an alignment tool. The tool insures that the pins/tails cut on subsequent settings will be indexed perfectly wiih the initial cuts, The alignment tool is available from Aspen Kits, the Hardware Kit supplier (sec sources). When you are working with w ider stock, you can use the stop for your initial cuts, but the stop would be in the way on the subsequent cuts. Just make sure thai ihe workpiece is flush and tigln against ihe bottom of the template when you clamp it up. The illustration shows the alignment tool in use. Keep in mind that the lool is used only to align the workpiece for clamping. Once the workpiece is clamped securely, the alignment tool is removed. You'll need lo use ihe alignment lixil when cutting both the pins and the tails. Determining Stock W idth; Dovetails look best when they are balanced with a half-pin at each edge. We designed our coffee table drawers so that the drawer height was a perfect multiple of our I '/ift in. on center dovetail spacing. On the coffee table drawers, the 3-Vift in. w idth of the drawer stock allowed for three tails, separated by two full pins, wiih a half pin on each edge. To take advantage of this "ideal"' look, your drawers, boxes or whatever other constructions you are making must be a multiple of I !/ir> in. The smallest width producing this uniform dovetail layout would be I '/ir> in. which would have a single tail flanked h\ half pins. A 2'/s in. width would have a pair of tails separated by a single pin and flanked by ? pair of half pins, and so on. While dovetails look l>cst when they arc balanced, that's not always possible. It's perfect!} acceptable to use other dimensions, so long as the dimension does not terminate too close to a line w here a tail and pin meet. May/June I'm 4.1 |