Woodworker's Journal 2001-25-1, страница 58

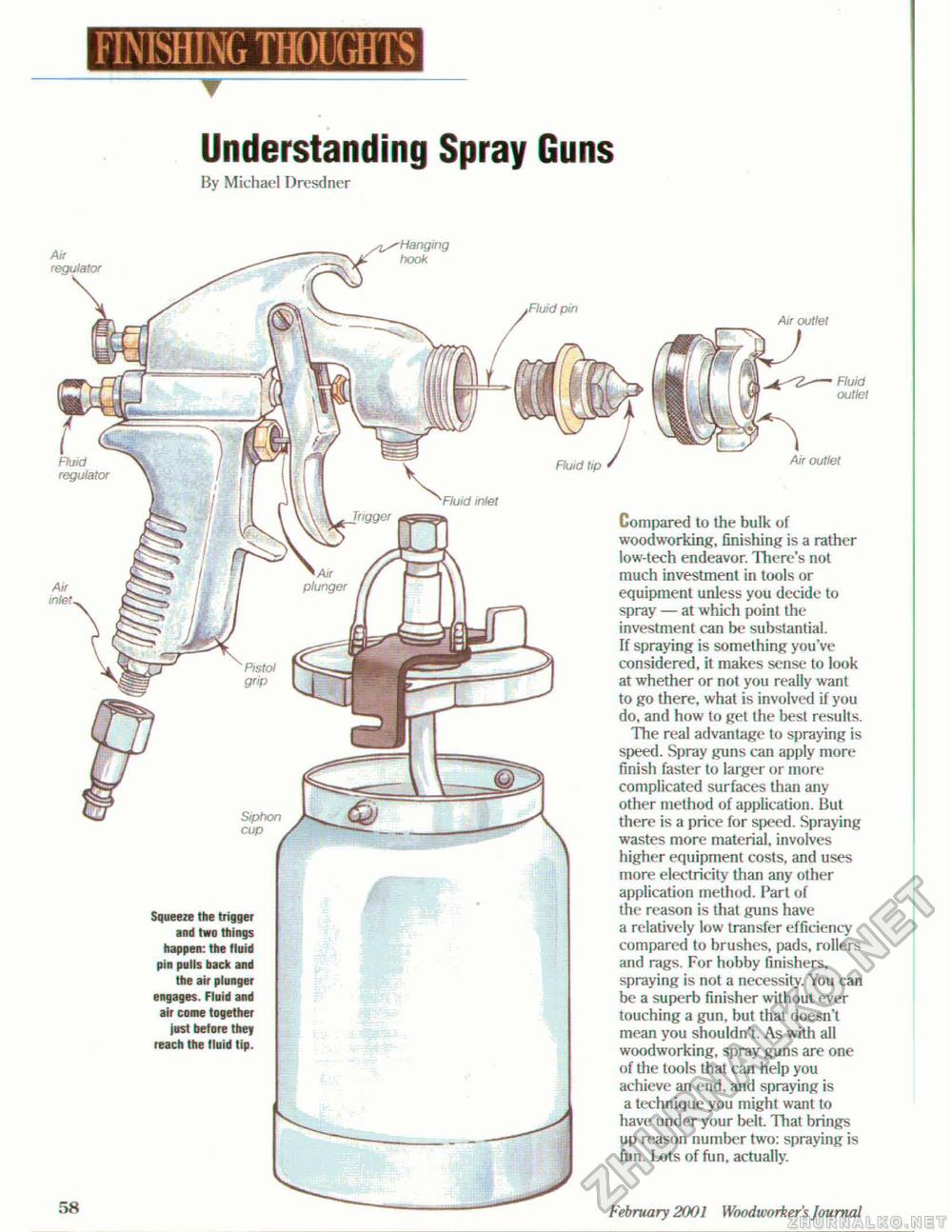

Understanding Spray Guns By Michael Dresdner Air regulator Hanging Hook Fluid pin Squeeze the trigger and two things happen: the fluid pin pulls back and the air plunger engages. Fluid and air come together just before they reach the fluid tip. 58 Air outlet Fluid outlet Air outlet Compared to the bulk of woodworking, finishing is a rather low-tech endeavor. There's not much investment in tools or equipment unless you decide to spray — at which point the investment can be substantial. If spraying is something you've considered, it makes sense to look at whether or not you really want to go there, what is involved if you do, and how to gel the best results. The real advantage to spraying is speed. Spray guns can apply more finish faster to larger or more complicated surfaces than any other method of application. But there is a price for speed. Spraying wastes more material, involves higher equipment costs, and uses more electricity than any other application method. Part of the reason is that guns have a relatively low transfer efficiency compared to brushes, |jads, rollers and rags. For hobby finishers, spraying is not a necessity. You can be a superb finisher without ever touching a gun, but that doesn't mean you shouldn't. As with all woodworking, spray guns are one of the tools that can help you achieve an end, and spraying is a technique you might want to have under your belt That brings up reason number two: spraying is fun. Lots of fun, actually. February 2001 Wood wo rker's Jo u mat |