Woodworker's Journal 2001-25-1, страница 62

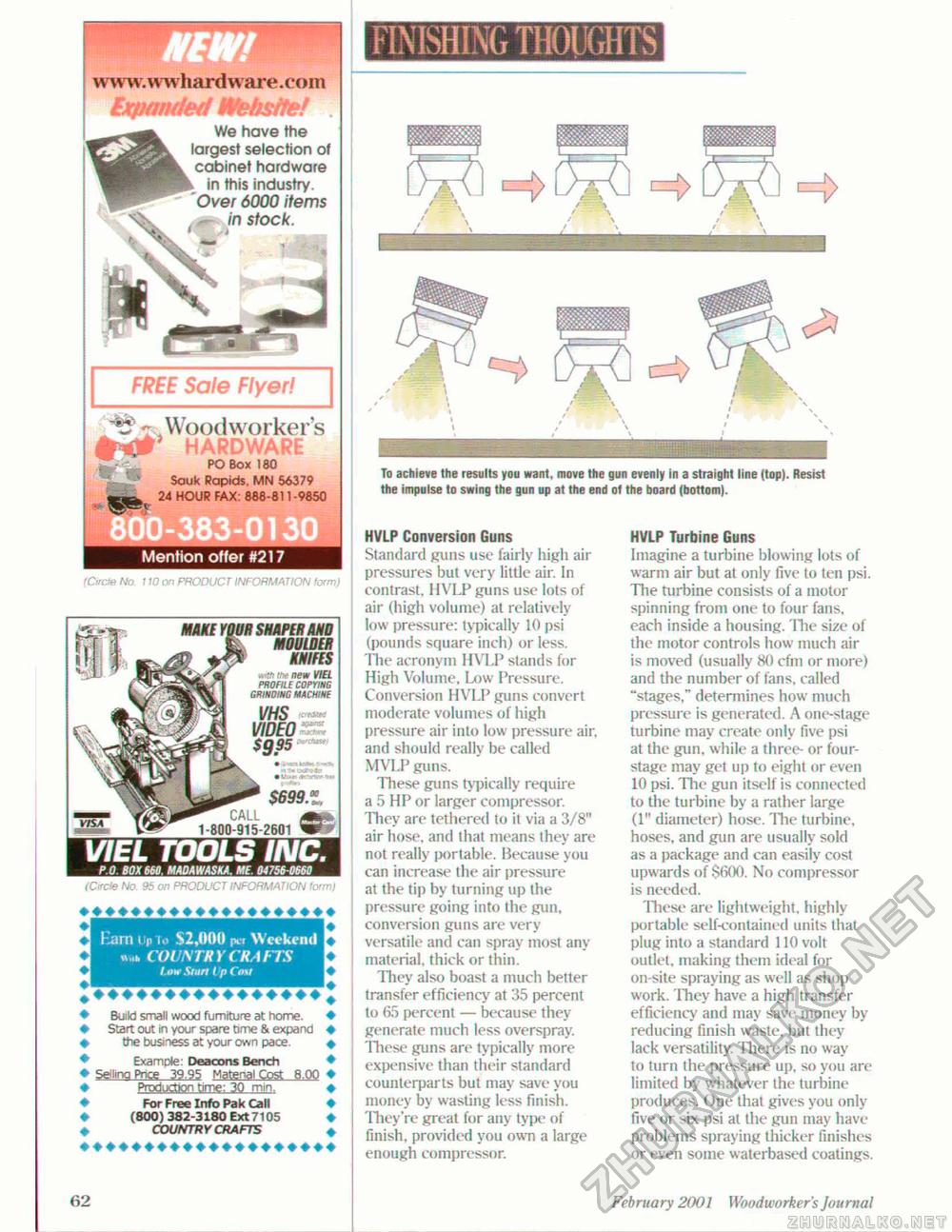

Expanded Website! We have the largest selection of cabinet hardware v in this industry. Over 6000 items in stock. FREE Sale Flyer! ^ - Woodworker's HARDWARE PO Bo* 180 Sauk Rapids. MN 56379 24 HOUR FAX: 088-811-9850 00-383-0130 Mention offer #217 fCircle No 110 on PRODUCT INFORMATION form) (Circle No 95 on PRODUCT INFORMATION rorm) ♦ ♦ ♦ ♦ Barn tip io $2,000 pa Weekend COUNTRY CRAFTS Low Stur! t p Cast ♦ Build small wood furniture at home. ♦ Start out in your spare time & expand + the business at your own pace. Example: Deacons Bench ♦ Selling Pnce 39.95 Matenal Cost 8.00 ♦ Production time: 30 min. ♦ For Free Info Pak Call ♦ (800) 382-3180 Ext 7105 ♦ COUNTRY CRAFTS hiflttiiiflfiMifiiiftiiiM To achieve the results you want, move the gun evenly in a straight line (top). Resist the impulse to swing the gun op at the end ot the board (bottom). HVLP Conversion Guns Standard guns use fairly high air pressures but very little air. In contrast, HVLP guns use lots of air (high volume) at relatively low pressure: typically 10 psi (pounds square inch) or less. The acronym HVLP stands for High Volume, Low IYessure. Conversion HVLP guns convert moderate volumes of high pressure air into low pressure air. and should really be called MVLP guns. These guns typically require a 5 HP or larger compressor. They are tethered lo it via a 3/8" air hose, and that means they are not really j)ortable. Because you can increase the air pressure at the tip by turning up the pressure going into the gun, conversion guns are very versatile and can spray most any material, thick or thin. They also boast a much better transfer efficiency at 35 percent to 65 percent — because they generate much less overspray. These guns are typically more expensive than their standard counterparts but may save you money by wasting less finish. They're great for any type of finish, provided you own a large enough compressor. HVLP Turbine Guns Imagine a turbine blowing lots of warm air but at only five to ten psi. The turbine consists of a motor spinning from one to four fans, each inside a housing. The size of the motor controls how much air is moved (usually 80 cfm or more) and the number of fans, called "stages," determines how much pressure is generated. A one-stage turbine may create only five psi at the gun. while a three- or four-stage may get up to eight or even 10 psi. The gun itself is connected to the turbine by a rather large (1" diameter) hose. The turbine, hoses, and gun are usually sold as a package and can easily cost upwards of $600. No compressor is needed. These are lightweight, highly portable self-contained units that plug into a standard 110 volt outlet, making them ideal for on-site spraying as well as shop work. They have a high transfer efficiency and may save money by reducing finish waste, but they lack versatility. There is no way to turn the pressure up, so you are limited by whatever the turbine produces. One that gives you only five or six psi at die gun may have problems spraying thicker finishes or even some waterbased coatings. MAI wrtfi the new VIEL PROFILE COPYING GRINDING MACHINE VHS VIDEO w $g95 WSf • . —- , i • jdhote • UiWlTd.-'V (fnHn $699.;, CALL Q. 62 February 2001 Wood wo rker's Jo u mat |