Woodworker's Journal 2002-26-3, страница 18

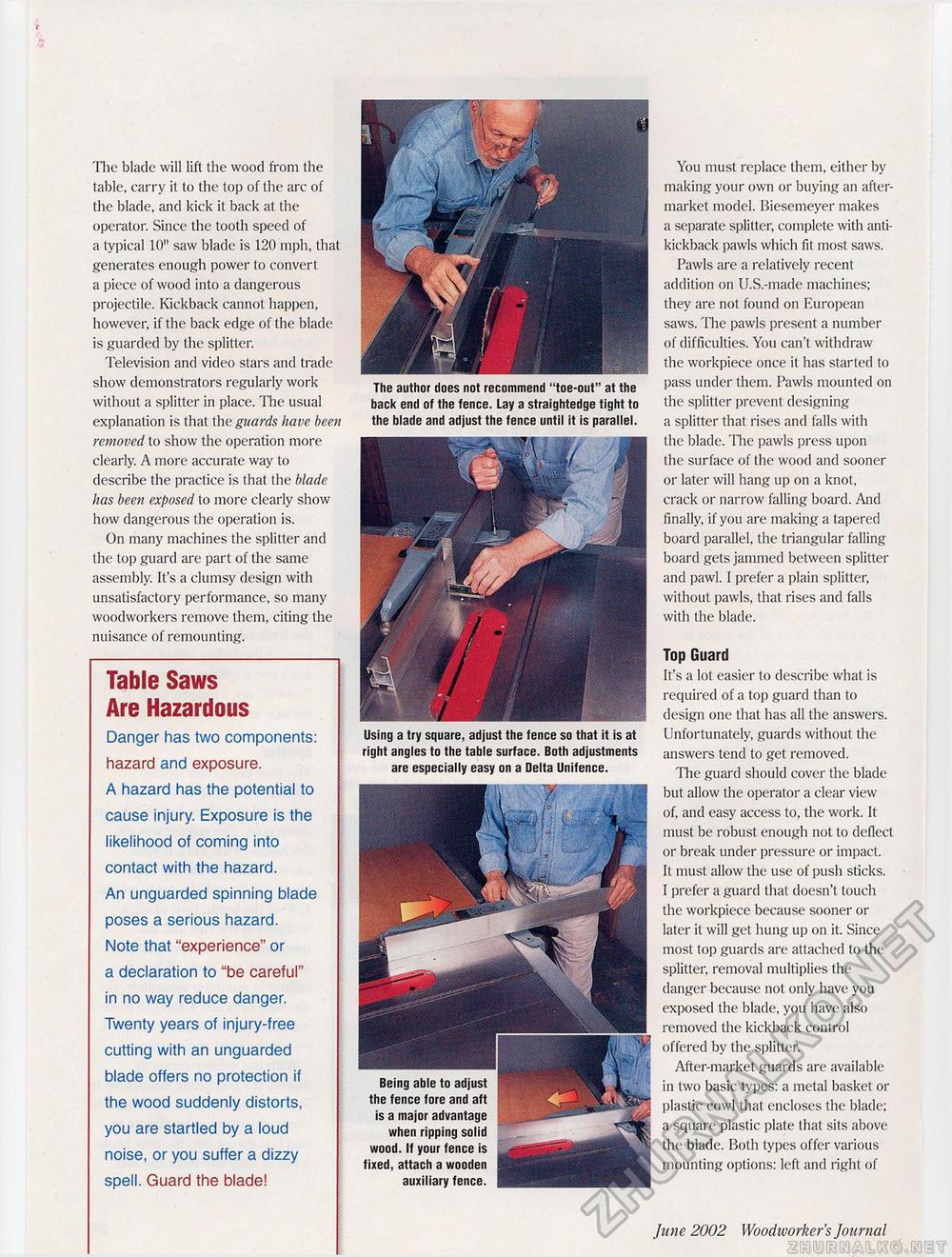

'Hie blade will lift the wood from the table, carry it to the top of the arc of the blade, and kick it back at the operator. Since the tooth speed of a typical 10" saw blade is 120 mph, that generates enough power to convert a piece of wood into a dangerous projectile. Kickback cannot happen, however, if the back edge of the blade is guarded by the splitter. Television and video stars and trade show demonstrators regularly work without a splitter in place. The usual explanation is that the guards have been removed to show the operation more clearly. A more accurate way to describe the practice is that the blade has been exposed to more clearly show how dangerous (he operation is. On many machines the splitter and the lop guard are part of the same assembly. It's a clumsy design with unsatisfactory performance, so many woodworkers remove them, citing the nuisance of remounting. The author does not recommend "toe-out" at the back end of the fence. Lay a straightedge tight to the blade and adjust the fence until it is parallel. You must replace them, either by making your own or buying an after-market model. Biesemeyer makes a separate splitter, complete with anti-kickback pawls which fit most saws. Pawls are a relatively recent addition on U.S.-made machines; they are not found on European saws. The pawls present a number of difficulties. You can't withdraw the workpiece once it has started to pass under them. Pawls mounted on the splitter prevent designing a splitter that rises and falls with the blade. The pawls press upon the surface of the wood and sooner or later will hang up on a knot, crack or narrow falling board. And finally, if you arc making a tapered board parallel, the triangular falling board gets jammed between splitter and pawl. I prefer a plain splitter, without pawls, that rises and falls with the blade. Top Guard It's a lot easier to describe what is required of a top guard than to design one that has all the answers. Unfortunately, guards without the answers tend to get removed. The guard should cover the blade but allow the operator a clear view of, and easy access to, the work. It must be robust enough not to deflect or break under pressure or impact. It must allow the use of push sticks. I prefer a guard that doesn't touch the workpiece because sooner or later it will get hung up on it. Since most top guards are attached to the splitter, removal multiplies the danger because not only have you exposed the blade, you have also removed the kickback control offered by the splitter. After-market guards are available in two basic types: a metal basket or plastic cowl that encloses the blade; a square plastic plate that sits above the blade. Both types offer various mounting options: left and right of 18 June 2002 Woodworker's Journal Table Saws Are Hazardous Danger has two components: hazard and exposure. A hazard has the potential to cause injury. Exposure is the likelihood of coming into contact with the hazard. An unguarded spinning blade poses a serious hazard. Note that "experience" or a declaration to "be careful" in no way reduce danger. Twenty years of injury-free cutting with an unguarded blade offers no protection if the wood suddenly distorts, you are startled by a loud noise, or you suffer a dizzy spell. Guard the blade! Using a try square, adjust the fence so that it is at right angles to the table surface. Both adjustments are especially easy on a Delta Unifence. Being able to adjust the fence fore and aft is a major advantage when ripping solid wood. If your fence is fixed, attach a wooden auxiliary fence. |