Woodworker's Journal 2002-26-3, страница 17

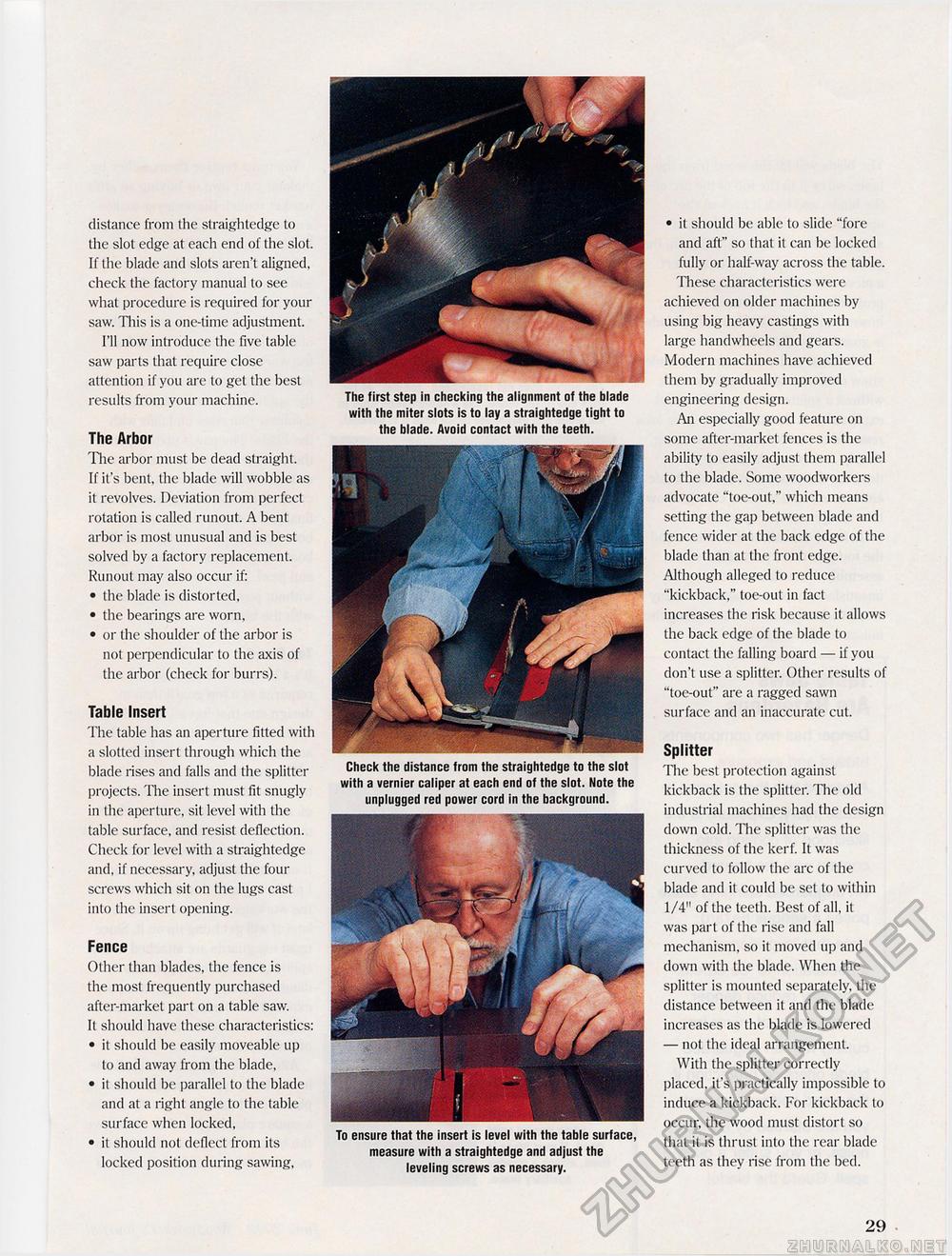

distance from the straightedge to the slot edge at each end of the slot. If the blade and slots aren't aligned, check the factory manual to see what procedure is required for your saw. This is a one-time adjustment. I'll now introduce the five table saw parts that require close attention if you are to get the best results from your machine. The Arbor The arbor must be dead straight. If it's bent, the blade will wobble as it revolves. Deviation from perfect rotation is called runout. A bent arbor is most unusual and is best solved by a factory replacement. Runout may also occur if: • the blade is distorted, • the bearings are worn, • or the shoulder of the arbor is not perpendicular to the axis of the arbor (check for burrs). Table Insert The table has an aperture fitted with a slotted insert through which the blade rises and falls and the splitter projects. The insert must fit snugly in (he aperture, sit level with the table surface, and resist deflection. Check for level with a straightedge and, if necessary, adjust the four screws which sit on the lugs cast into the insert opening. Fence Other than blades, the fence is the most frequently purchased after-market part on a table saw. It should have these characteristics: • it should be easily moveable up to and away from the blade, • it should be parallel to the blade and at a right angle to the table surface when locked, • it should not deflect from its locked position during sawing, The first step in checking the alignment of the blade with the miter slots is to lay a straightedge tight to the blade. Avoid contact with the teeth. Check the distance from the straightedge to the slot with a vernier caliper at each end of the slot. Note the unplugged red power cord in the background. To ensure that the insert is level with the table surface, measure with a straightedge and adjust the leveling screws as necessary. • it should be able to slide "fore and aft" so that it can be locked fully or half-way across the table. These characteristics were achieved on older machines by using big heavy castings with large handwheels and gears. Modern machines have achieved them by gradually improved engineering design. An especially good feature on some after-market fences is the ability to easily adjust them parallel to the blade. Some woodworkers advocate "toe-out," which means setting the gap between blade and fcnce wider at the back edge of the blade than at the front edge. Although alleged to reduce "kickback," toe-out in fact increases the risk because it allows the back edge of the blade to contact the falling board — if you don't use a splitter. Other results of "toe-out" are a ragged sawn surface and an inaccurate cut. Splitter The best protection against kickback is the splitter. The old industrial machines had the design down cold. The splitter was the thickness of the kerf. It was curved to follow the arc of the blade and it could be set to within 1/4" of the teeth. Best of all, it was part of the rise and fall mechanism, so it moved up and down with the blade. When the splitter is mounted separately, the distance between it and the blade increases as the blade is lowered — not the ideal arrangement. With the splitter correctly placed, it's practically impossible to induce a kickback. For kickback to occur, the wood must distort so that it is thrust into the rear blade teeth as they rise from the bed. 29 |