Woodworker's Journal 2002-26-3, страница 19

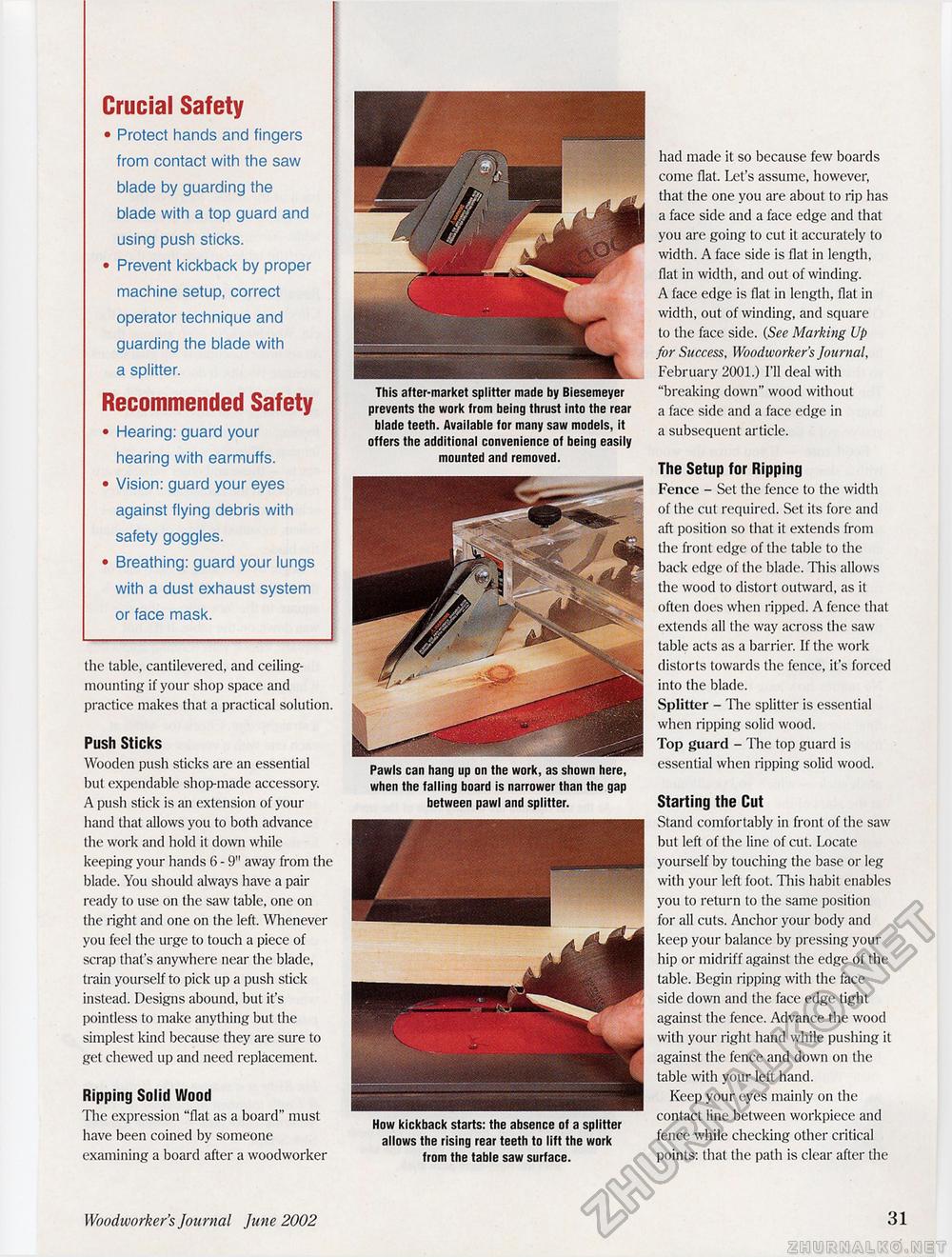

Crucial Safety • Protect hands and fingers from contact with the saw blade by guarding the blade with a top guard and using push sticks. • Prevent kickback by proper machine setup, correct operator technique and guarding the blade with a splitter. Recommended Safety • Hearing: guard your hearing with earmuffs. • Vision: guard your eyes against flying debris with safety goggles. • Breathing: guard your lungs with a dust exhaust system or face mask. the table, cantilevered, and ceiling-mounting if your shop space and practice makes that a practical solution. Push Sticks Wooden push sticks are an essential but expendable shop-made accessory. A push stick is an extension of your hand that allows you to both advance the work and hold it down while keeping your hands 6 - 9" away from the blade. You should always have a pair ready to use on the saw table, one on the right and one on the left. Whenever you feel the urge to touch a piece of scrap that's anywhere near the blade, train yourself to pick up a push stick instead. Designs abound, but it's pointless to make anything but the simplest kind because they are sure to get chewed up and need replacement. Ripping Solid Wood The expression "flat as a board" must have been coined by someone examining a board after a woodworker This after-market splitter made by Biesemeyer prevents the work from being thrust into the rear blade teeth. Available for many saw models, It offers the additional convenience of being easily mounted and removed. Pawls can hang up on the work, as shown here, when the falling board is narrower than the gap between pawl and splitter. How kickback starts: the absence of a splitter allows the rising rear teeth to lift the work from the table saw surface. had made it so because few boards come flat. Let's assume, however, that the one you are about to rip has a face side and a face edge and that you are going to cut it accurately to width. A face side is flat in length, flat in width, and out of winding. A face edge is flat in length, flat in width, out of winding, and square to the face side. (See Marking Up for Success, Woodworker's Journal, February 2001.) I'll deal with "breaking down" wood without a face side and a face edge in a subsequent article. The Setup for Ripping Fence - Set the fence to the width of the cut required. Set its fore and aft position so that it extends from the front edge of the table to the back edge of the blade. This allows the wood to distort outward, as it often does when ripped. A fence that extends all the way across the saw table acts as a barrier. If the work distorts towards the fence, it's forced into the blade. Splitter - The splitter is essential when ripping solid wood. Top guard - The top guard is essential when ripping solid wood. Starting the Cut Stand comfortably in front of the saw but left of the line of cut. Locate yourself by touching the base or leg with your left foot. This habit enables you to return to the same position for all cuts. Anchor your body and keep your balance by pressing your hip or midriff against the edge of the table. Begin ripping with the face side down and the face edge tight against the fence. Advance the wood with your right hand while pushing it against the fence and clown on the table with your left hand. Keep your eyes mainly on the contact line between workpiece and fence while checking other critical points: that the path is clear after the Woodworker's Journal June 2002 31 |