Woodworker's Journal 2002-26-3, страница 22

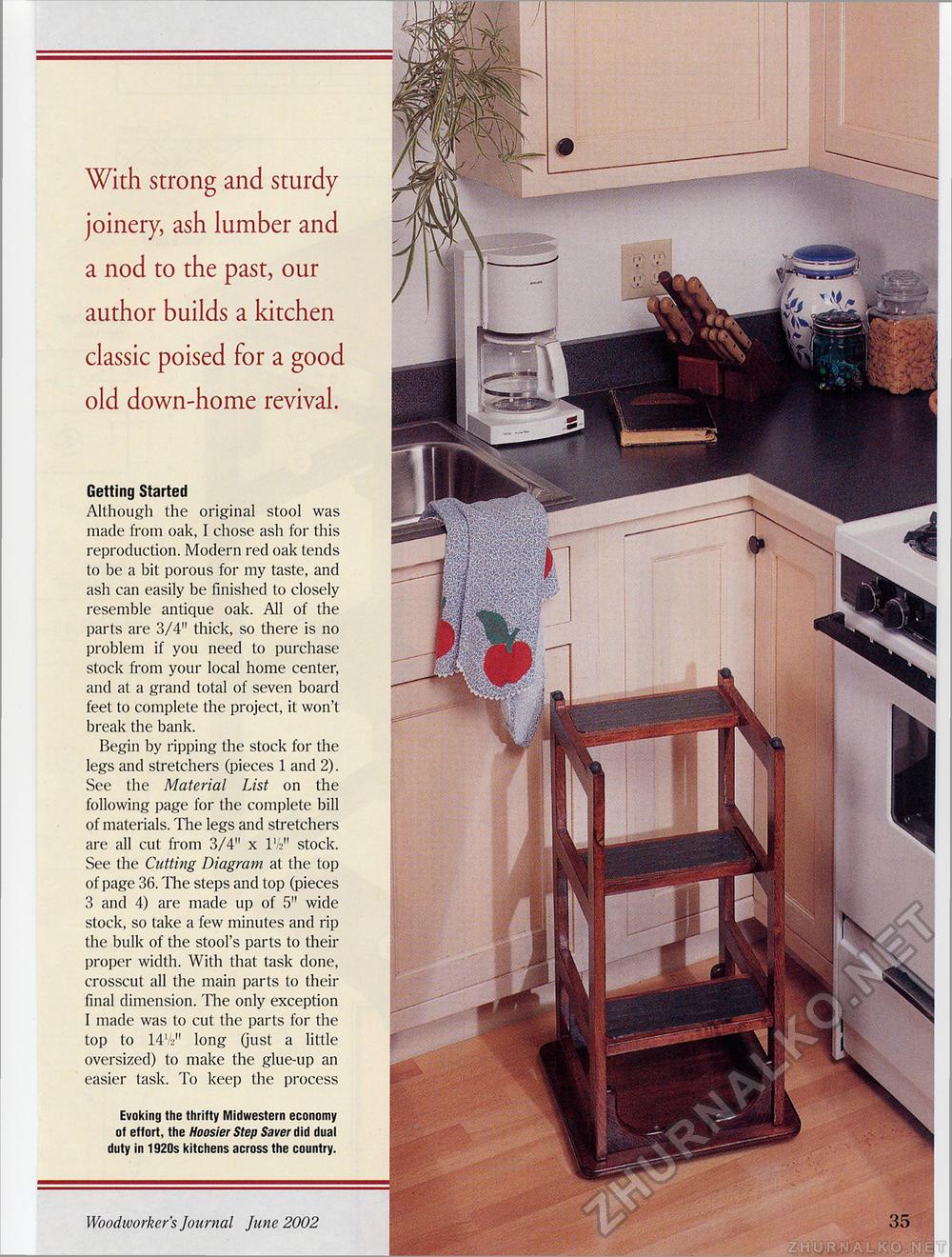

With strong and sturdy joinery, ash lumber and a nod to the past, our author builds a kitchen classic poised for a good old down-home revival. Getting Started Although the original stool was made from oak, I chose ash for this reproduction. Modern red oak tends to be a bit porous for my taste, and ash can easily be finished to closely resemble antique oak. All of the parts are 3/4" thick, so there is no problem if you need to purchase stock from your local home center, and at a grand total of seven board feet to complete the project, it won't break the bank. Begin by ripping the stock for the legs and stretchers (pieces 1 and 2). See the Material List on the following page for the complete bill of materials. The legs and stretchers are all cut from 3/4" x Ykn stock. See the Cutting Diagram at the top of page 36. The steps and top (pieces 3 and 4) are made up of 5" wide stock, so take a few minutes and rip the bulk of the stool's parts to their proper width. With that task done, crosscut all the main parts to their final dimension. The only exception I made was to cut the parts for the top to 14V2M long (just a little oversized) to make the glue-up an easier task. To keep the process Evoking the thrifty Midwestern economy of effort, the Hoosier Step Saver did dual duty in 1920s kitchens across the country. Woodworker's Journal June 2002 22 |