Woodworker's Journal 2002-26-3, страница 20

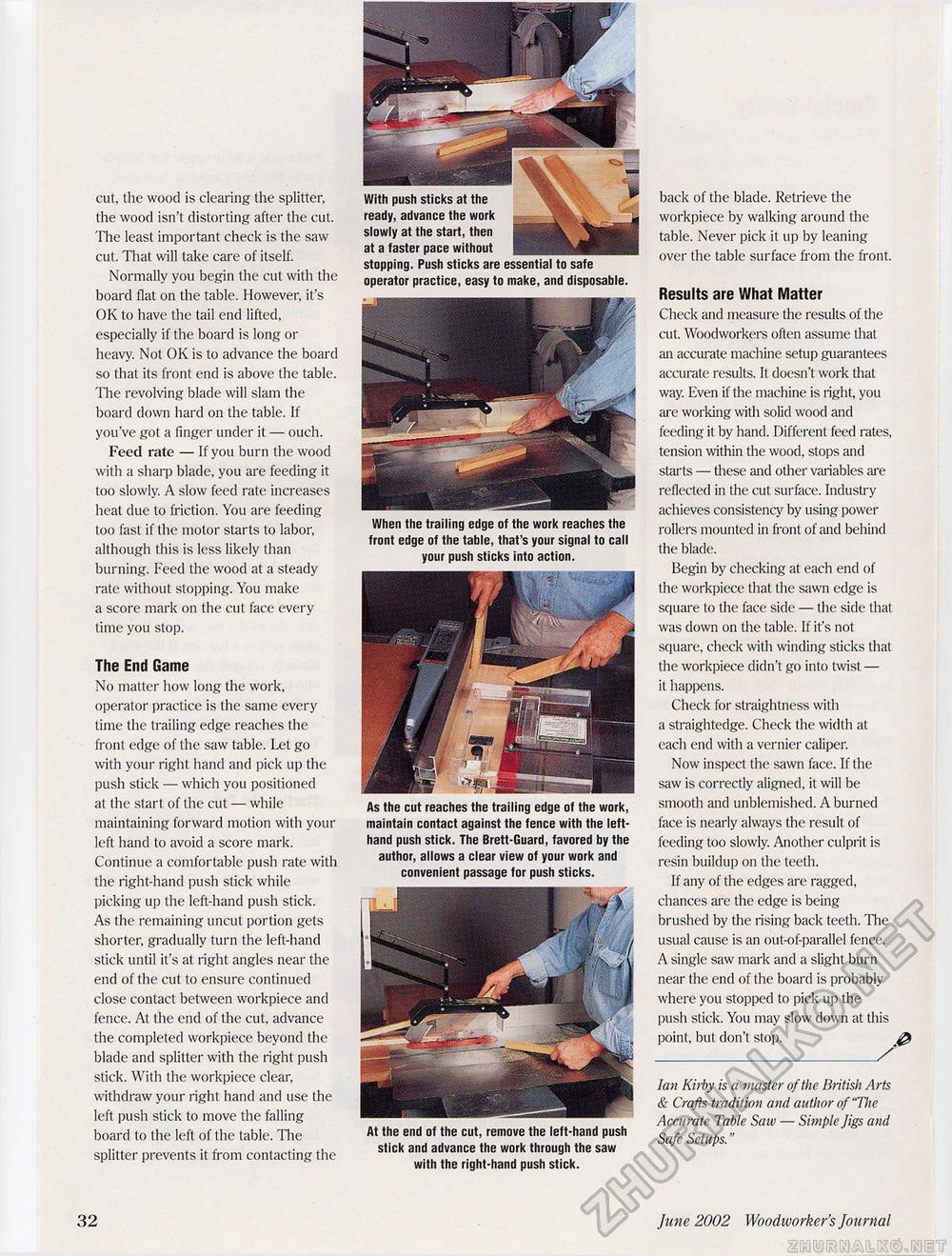

cut, the wood is clearing the splitter, the wood isn't distorting after the cut. The least important check is the saw cut. That will lake care of itself. Normally you begin the cut with the board flat on the table. However, it's OK to have the tail end lifted, especially if the board is long or heavy. Not OK is to advance the board so that its front end is above the table. The revolving blade will slam (he board clown hard on the table. If you've got a finger under it — ouch. Feed rate — If you burn the wood with a sharp blade, you are feeding it too slowly. A slow feed rate increases heat clue to friction. You are feeding too fast if the motor starts to labor, although this is less likely than burning. Feed the wood at a steady rate without stopping. You make a score mark on Ihe cut face every time you stop. The End Game No matter how long the work, operator practice is the same every time the trailing edge reaches the front edge of the saw table. Let go with your right hand and pick up the push stick — which you positioned at the start of the cut — while maintaining forward motion with your left hand to avoid a score mark. Continue a comfortable push rate with the right-hand push stick while picking up the left-hand push stick. As the remaining uncut portion gets shorter, gradually turn the left-hand stick until it's at right angles near the end of the cut to ensure continued close contact between workpiece and fence. At the end of the cut. advance the completed workpiece beyond the blade and splitter with the right push stick. With the workpiece clear, withdraw your right hand and use the left push stick to move the falling board to the left of the table. The splitter prevents it from contacting the back of the blade. Retrieve the workpiece by walking around the table. Never pick it up by leaning over the table surface from the front. Results are What Matter Check and measure the results of the cut. Woodworkers often assume that an accurate machine setup guarantees accurate results. It doesn't work that way. Even if the machine is right, you are working with solid wood and feeding it by hand. Different feed rates, tension within the wood, stops and starts — these and other variables are reflected in the cut surface. Industry achieves consistency by using power rollers mounted in front of and behind the blade. Begin by checking at each end of the workpiece that the sawn edge is square to the face side — the side that was down on the table. If it's not square, check with winding sticks that the workpiece didn't go into twist — it happens. Check for straightness with a straightedge. Check the width at each end with a vernier caliper. Now inspect the sawn face. If the saw is correctly aligned, it will be smooth and unblemished. A burned face is nearly always the result of feeding too slowly. Another culprit is resin buildup on the teeth. If any of the edges are ragged, chances are the edge is being brushed by the rising back teeth. The usual cause is an out-of-parallel fence. A single saw mark and a slight burn near the end of the board is probably where you stopped to pick up the push stick. You may slow down at this point, but don't stop. j Ian Kirby is a master of the British Arts & Crafts tradition and author of "The Accurate Table Saw — Simple Jigs and Safe Setups." When the trailing edge of the work reaches the front edge of the table, that's your signal to call your push sticks into action. As the cut reaches the trailing edge of the work, maintain contact against the fence with the left-hand push stick. The Brett-Guard, favored by the author, allows a clear view of your work and convenient passage for push sticks. At the end of the cut, remove the left-hand push stick and advance the work through the saw with the right-hand push stick. With push sticks at the ready, advance the work slowly at the start, then at a faster pace without stopping. Push sticks are essential to safe operator practice, easy to make, and disposable. 32 June 2002 Woodworker's Journal |