Woodworker's Journal 2004-28-6, страница 36

Jointing with a RouterBy Carol Reed ant a jointer in your shop? Most of us do, but not all of us have enough floor space or a big enough wallet. However, if you have a router, almost any size, you can make a jointing jig that in my opinion does some tasks better than a "real" jointer. The secret is a spiral-flute router bit that, unlike the knives of most conventional jointers, produces tearout-free jointing on squirrely grained or bird's-eye figured wood. Even if you do have a jointer but often work in these lovely but difficult to machine woods — especially in smaller dimensions — a router-jointer jig will consistently create a smoother surface. The router-jointer jig also allows you to joint clean plywood edges and other composite or even plastic materials, a task that can quickly dull the knives of a conventional jointer, especially if the plies are bonded with a hard glue. A conventional jointer will perform two operations, The most common operation is edge jointing. The other is face jointing. Many of us only edge joint because we buy our wood already surfaced (face jointed). This router jointer jig will yield smooth, accurate edges — safely, comfortably, and consistently — for the price of a long spiral bit and a few square feet of plywood. The jig has four components: a router, a spiral flute bit, the table and the fence. Ideally, the router should have a 1/2" collet because larger diameter bits run smoother and make

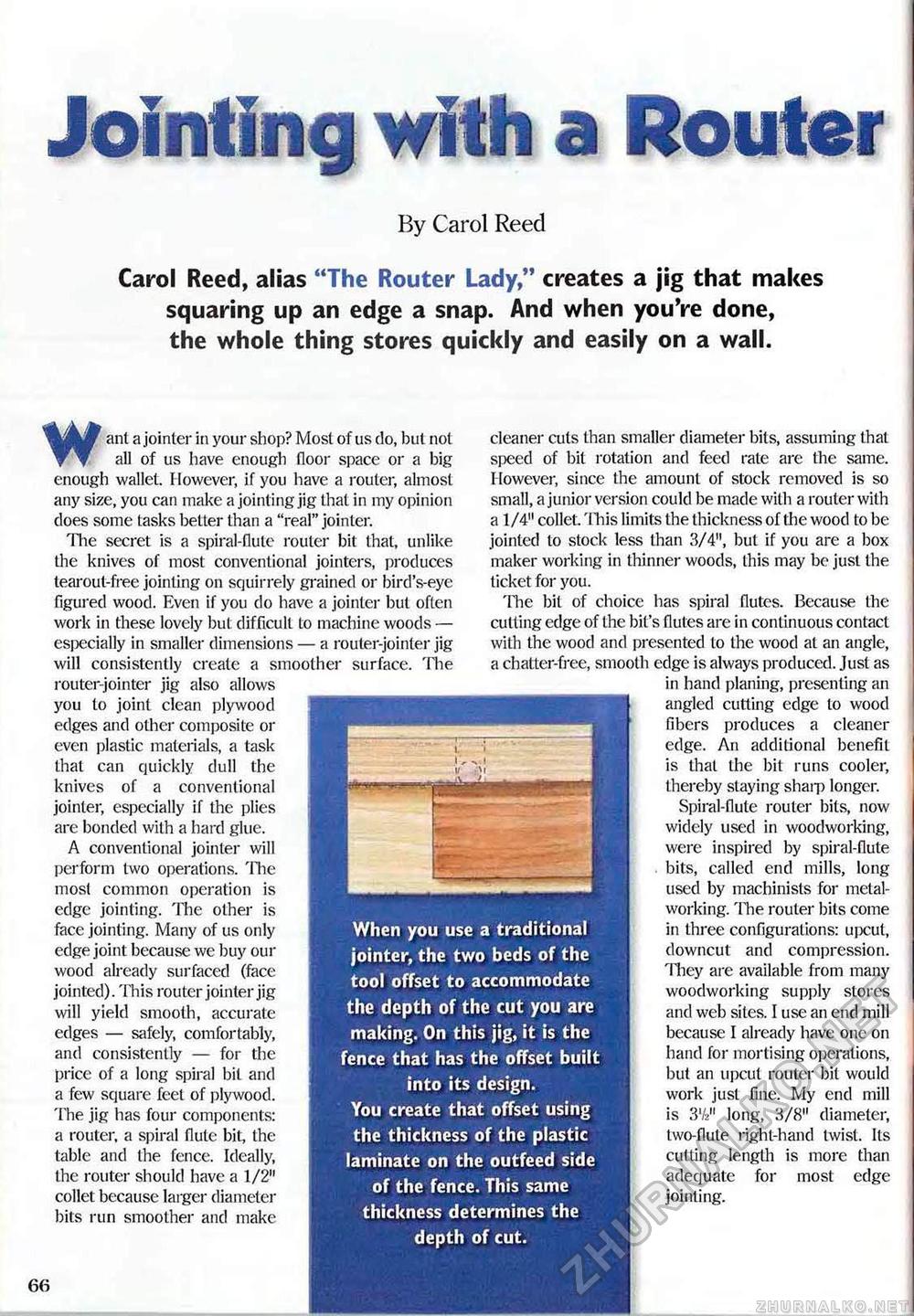

When you use a traditional jointer, the two beds of the tool offset to accommodate the depth of the cut you are making. On this jig, it is the fence that has the offset built into its design. You create that offset using the thickness of the plastic laminate on the outfeed side of the fence. This same thickness determines the depth of cut. cleaner cuts than smaller diameter bits, assuming that speed of bit rotation and feed rate are the same. However, since the amount of stock removed is so small, a junior version could be made with a router with a 1/4" collet. This limits the thickness of the wood to be jointed to stock less than 3/4", but if you are a box maker working in thinner woods, this may be just the ticket for you. The bit of choice has spiral flutes. Because the cutting edge of the bit's flutes are in continuous contact with the wood and presented to the wood at an angle, a chatter-free, smooth edge is always produced. Just as in hand planing, presenting an angled cutting edge to wood fibers produces a cleaner edge. An additional benefit is that the bit runs cooler, thereby staying shaip longer. Spiral-flute router bits, now widely used in woodworking, were inspired by spiral-flute . bits, called end mills, long used by machinists for metal-working. The router bits come in three configurations: upcut, downcut and compression. They are available from many woodworking supply stores and web sites. I use an end mill because I already have one on hand for mortising operations, but an upcut router bit would work just fine. My end mill is 3W long, 3/8" diameter, two-flute right-hand twist. Its cutting length is more than adequate for most edge jointing. Carol Reed, alias "The Router Lady," creates a jig that makes squaring up an edge a snap. And when you're done, the whole thing stores quickly and easily on a wall. |

|||||||||||||