Woodworker's Journal 2006-30-2, страница 36

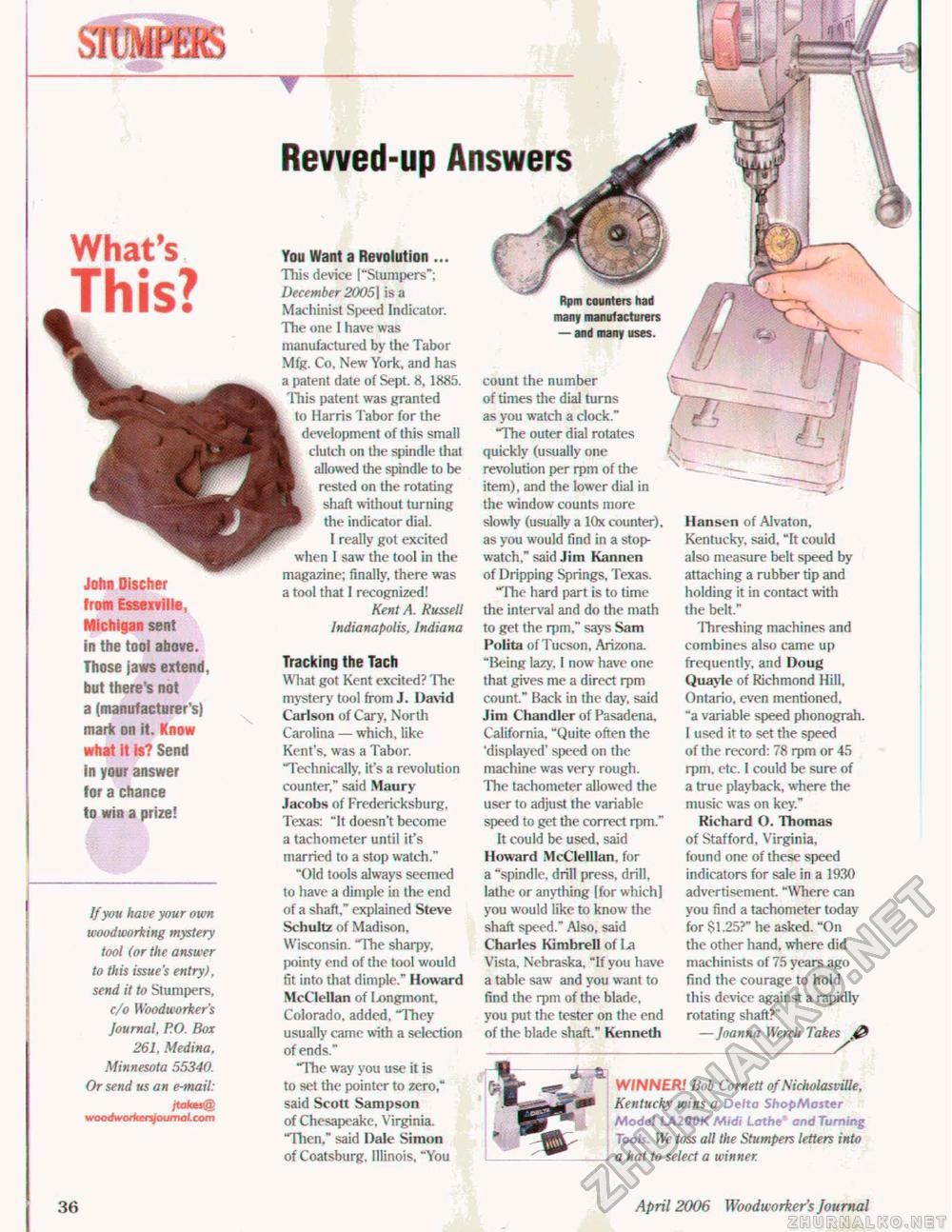

If you have your own woodworking mystery tool (or the answer to this issue's entry), send it to Stumpers, c/o Woodworker's Journal, P.O. Box 261, Medina, Minnesota 55340. Or send us an e-mail: jtakes@ woodworkersjoumal.com ▼ Revved-up Answers What's This? John Qischer from Essexville, Michigan sent in the tool above. Those jaws extend, but there's not a (manufacturer's) mark on it. Know what it is? Send in your answer for a chance to win a prize! You Want a Revolution ... This device ("Stumpers": December 2005| is a Machinist Speed Indicator. The one I have was manufactured by the Tabor Mfg. Co, New York, and has a patent date of Sept. 8,1885. This patent was granted to Harris Tabor for the development of this small clutch on the spindle that allowed the spindle to be rested on the rotating shaft without turning the indicator dial. I really got excited when I saw the tool in the magazine; finally, there was a tool that I recognized! Kent A. Russell Indianapolis, Indiana Tracking the Tach What got Kent excited? The mystery tool from J. David Carlson of Cary, North Carolina — which, like Kent's, was a Tabor. Technically, it's a revolution counter," said Maury Jacobs of Fredericksburg, Texas: "It doesn't become a tachometer until it's married to a stop watch." "Old tools always seemed to have a dimple in the end of a shaft," explained Steve Sehultz of Madison, Wisconsin. The sharpy, pointy end of the tool would fit into that dimple." Howard McClellan of Longmont, Colorado, added, They usually came with a selection of ends." The way you use it is to set the pointer to zero," said Scott Sampson of Chesapeake, Virginia. Then," said Dale Simon of Coatsburg. Illinois. "You Rpm many manufacturers — and many uses. count the number of times the dial turns as you watch a clock." The outer dial rotates quickly (usually one revolution per rpm of the item), and the lower dial in the window counts more slowly (usually a lQx counter), as you would find in a stopwatch." said Jim Kannen of Dripping Springs. Texas. The hard part is to time the interval and do the math to get the rpm." says Sam Folita of Tucson, Arizona. "Being lazy, I now have one that gives me a direct rpm count." Back in the day, said Jim Chandler of Pasadena, California, "Quite often the 'displayed' speed on the machine was very rough. The tachometer allowed the user to adjust the variable speed to get the correct rpm." It could be used, said Howard McClelllan. for a "spindle, drill press, drill, lathe or anything (for which] you would like to know the shaft speed." Also, said Charles Kimbrell of la Vista, Nebraska, "If you have a table saw and you want to find the rpm of the blade, you put the tester on the end of the blade shaft." Kenneth Hansen of Alvaton, Kentucky, said, "It could also measure belt speed by attaching a rubber tip and holding it in contact with the belt." Threshing machines and combines also came up frequently, and Doug Quayie of Richmond Hill, Ontario, even mentioned, "a variable speed phonograh. I used it to set the speed of the record: 78 rpm or 45 rpm, etc. 1 could be sure of a true playback, where the music was on key." Richard O. Thomas of Stafford, Virginia, found one of these speed indicators for sale in a 1930 advertisement. "Where can you find a tachometer today for $1.25?" he asked. "On the other hand, where did machinists of 75 years ago find the courage to hold this device against a rapidly rotating shaft?" —Joanna Werch Takes @ WINNER! Bob Cornett ofNicholasville, Kentucky wins a Delta ShopMaster Model LA200K Midi Lathef and Turning Tools. We toss all the Stumpers letters into a hat to select a winner. 36 April 2006 Woodworker's Journal |