Woodworker's Journal 2006-30-5, страница 28

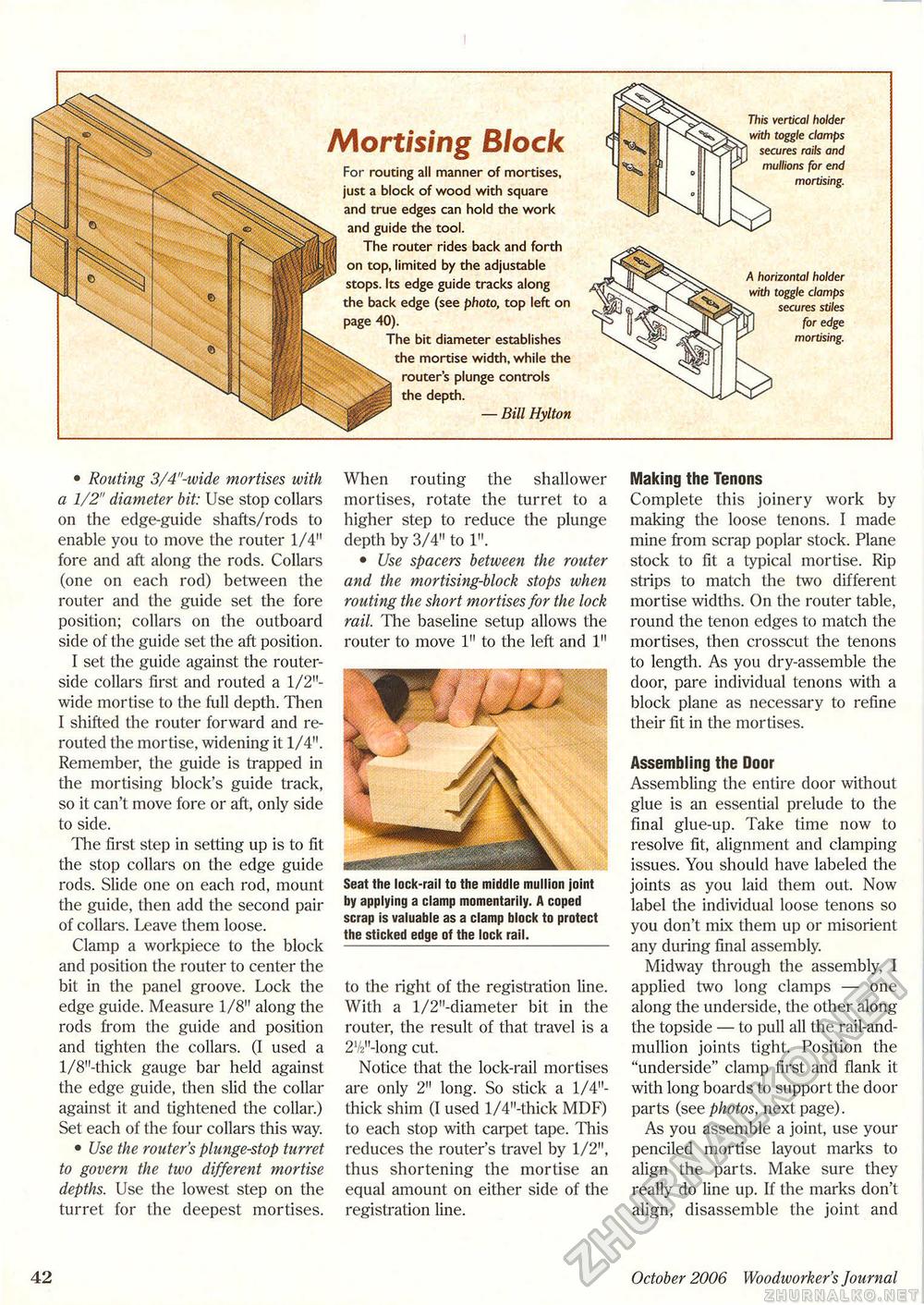

Mortising Block For routing all manner of mortises, just a block of wood with square and true edges can hold the work and guide the tool. The router rides back and forth on top, limited by the adjustable stops. Its edge guide tracks along the back edge (see photo, top left on page 40). The bit diameter establishes the mortise width, while the router's plunge controls the depth. — Bill Hylton mullions for end This vertical holder with toggle clamps secures rails and • Routing 3/4"-wide mortises with a 1/2" diameter bit: Use stop collars on the edge-guide shafts/rods to enable you to move the router 1/4" fore and aft along the rods. Collars (one on each rod) between the router and the guide set the fore position; collars on the outboard side of the guide set the aft position. I set the guide against the router-side collars first and routed a 1/2"-wide mortise to the full depth. Then I shifted the router forward and rerouted the mortise, widening it 1/4". Remember, the guide is trapped in the mortising block's guide track, so it can't move fore or aft, only side to side. The first step in setting up is to fit the stop collars on the edge guide rods. Slide one on each rod, mount the guide, then add the second pair of collars. Leave them loose. Clamp a workpiece to the block and position the router to center the bit in the panel groove. Lock the edge guide. Measure 1/8" along the rods from the guide and position and tighten the collars. (I used a l/8"-thick gauge bar held against the edge guide, then slid the collar against it and tightened the collar.) Set each of the four collars this way. • Use the router's plunge-stop turret to govern the two different mortise depths. Use the lowest step on the turret for the deepest mortises. When routing the shallower mortises, rotate the turret to a higher step to reduce the plunge depth by 3/4" to 1". • Use spacers between the router and the mortising-block stops when routing the short mortises for the lock rail. The baseline setup allows the router to move 1" to the left and 1" Seat the lock-rail to the middle mullion joint by applying a clamp momentarily. A coped scrap is valuable as a clamp block to protect the sticked edge of the lock rail. to the right of the registration line. With a l/2"-diameter bit in the router, the result of that travel is a 2V2"-long cut. Notice that the lock-rail mortises are only 2" long. So stick a 1/4"-thick shim (I used l/4"-thick MDF) to each stop with carpet tape. This reduces the router's travel by 1/2", thus shortening the mortise an equal amount on either side of the registration line. Making the Tenons Complete this joinery work by making the loose tenons. I made mine from scrap poplar stock. Plane stock to fit a typical mortise. Rip strips to match the two different mortise widths. On the router table, round the tenon edges to match the mortises, then crosscut the tenons to length. As you dry-assemble the door, pare individual tenons with a block plane as necessary to refine their fit in the mortises. Assembling the Door Assembling the entire door without glue is an essential prelude to the final glue-up. Take time now to resolve fit, alignment and clamping issues. You should have labeled the joints as you laid them out. Now label the individual loose tenons so you don't mix them up or misorient any during final assembly. Midway through the assembly, I applied two long clamps — one along the underside, the other along the topside — to pull all the rail-and-mullion joints tight. Position the "underside" clamp first and flank it with long boards to support the door parts (see photos, next page). As you assemble a joint, use your penciled mortise layout marks to align the parts. Make sure they really do line up. If the marks don't align, disassemble the joint and 42 October 2006 Woodivorker's Journal |