Woodworker's Journal 2006-30-5, страница 26

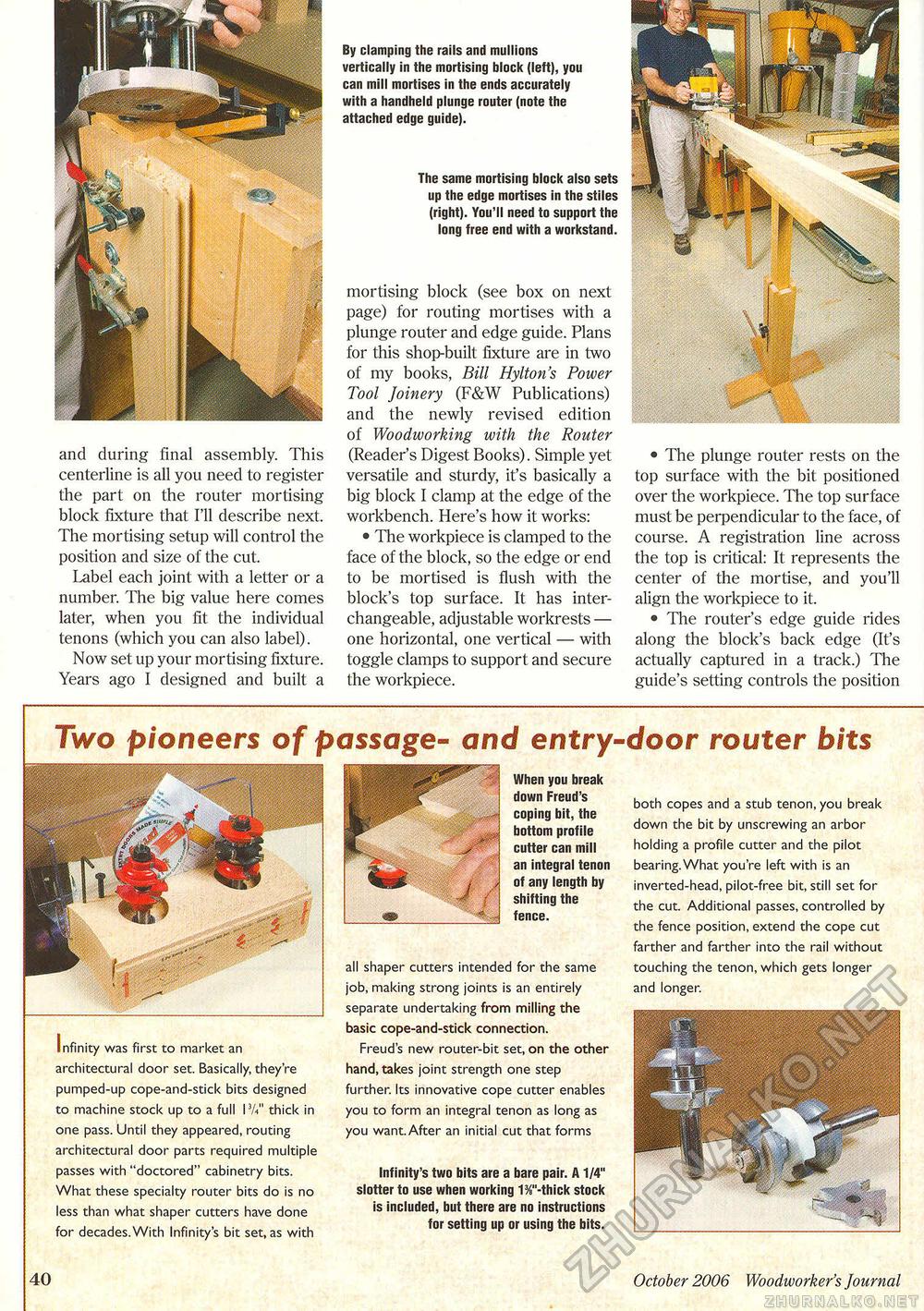

By clamping the rails and mullions vertically in the mortising block (left), you can mill mortises in the ends accurately with a handheld plunge router (note the attached edge guide). The same mortising block also sets up the edge mortises in the stiles (right). You'll need to support the long free end with a workstand. and during final assembly. This centerline is all you need to register the part on the router mortising block fixture that I'll describe next. The mortising setup will control the position and size of the cut. Label each joint with a letter or a number. The big value here comes later, when you fit the individual tenons (which you can also label). Now set up your mortising fixture. Years ago I designed and built a mortising block (see box on next page) for routing mortises with a plunge router and edge guide. Plans for this shop-built fixture are in two of my books, Bill Hylton's Power Tool Joinery (F&W Publications) and the newly revised edition of Woodworking with the Router (Reader's Digest Books). Simple yet versatile and sturdy, it's basically a big block I clamp at the edge of the workbench. Here's how it works: • The workpiece is clamped to the face of the block, so the edge or end to be mortised is flush with the block's top surface. It has interchangeable, adjustable workrests — one horizontal, one vertical — with toggle clamps to support and secure the workpiece. • The plunge router rests on the top surface with the bit positioned over the workpiece. The top surface must be perpendicular to the face, of course. A registration line across the top is critical: It represents the center of the mortise, and you'll align the workpiece to it. • The router's edge guide rides along the block's back edge (It's actually captured in a track.) The guide's setting controls the position Two pioneers of passage" and entry-door router bits Infinity was first to market an architectural door set. Basically, they're pumped-up cope-and-stick bits designed to machine stock up to a full l3A" thick in one pass. Until they appeared, routing architectural door parts required multiple passes with "doctored" cabinetry bits. What these specialty router bits do is no less than what shaper cutters have done for decades. With Infinity's bit set, as with both copes and a stub tenon, you break down the bit by unscrewing an arbor holding a profile cutter and the pilot bearing. What you're left with is an inverted-head, pilot-free bit, still set for the cut. Additional passes, controlled by the fence position, extend the cope cut farther and farther into the rail without touching the tenon, which gets longer and longer. When you break down Freud's coping bit, the bottom profile cutter can mill an integral tenon of any length by shifting the fence. all shaper cutters intended for the same job, making strong joints is an entirely separate undertaking from milling the basic cope-and-stick connection. Freud's new router-bit set, on the other hand, takes joint strength one step further. Its innovative cope cutter enables you to form an integral tenon as long as you want. After an initial cut that forms Infinity's two bits are a bare pair. A1/4" slotter to use when working 1%"-thick stock is included, but there are no instructions for setting up or using the bits. 40 October 2006 Woodivorker's Journal |