Woodworker's Journal 2008-32-1, страница 23

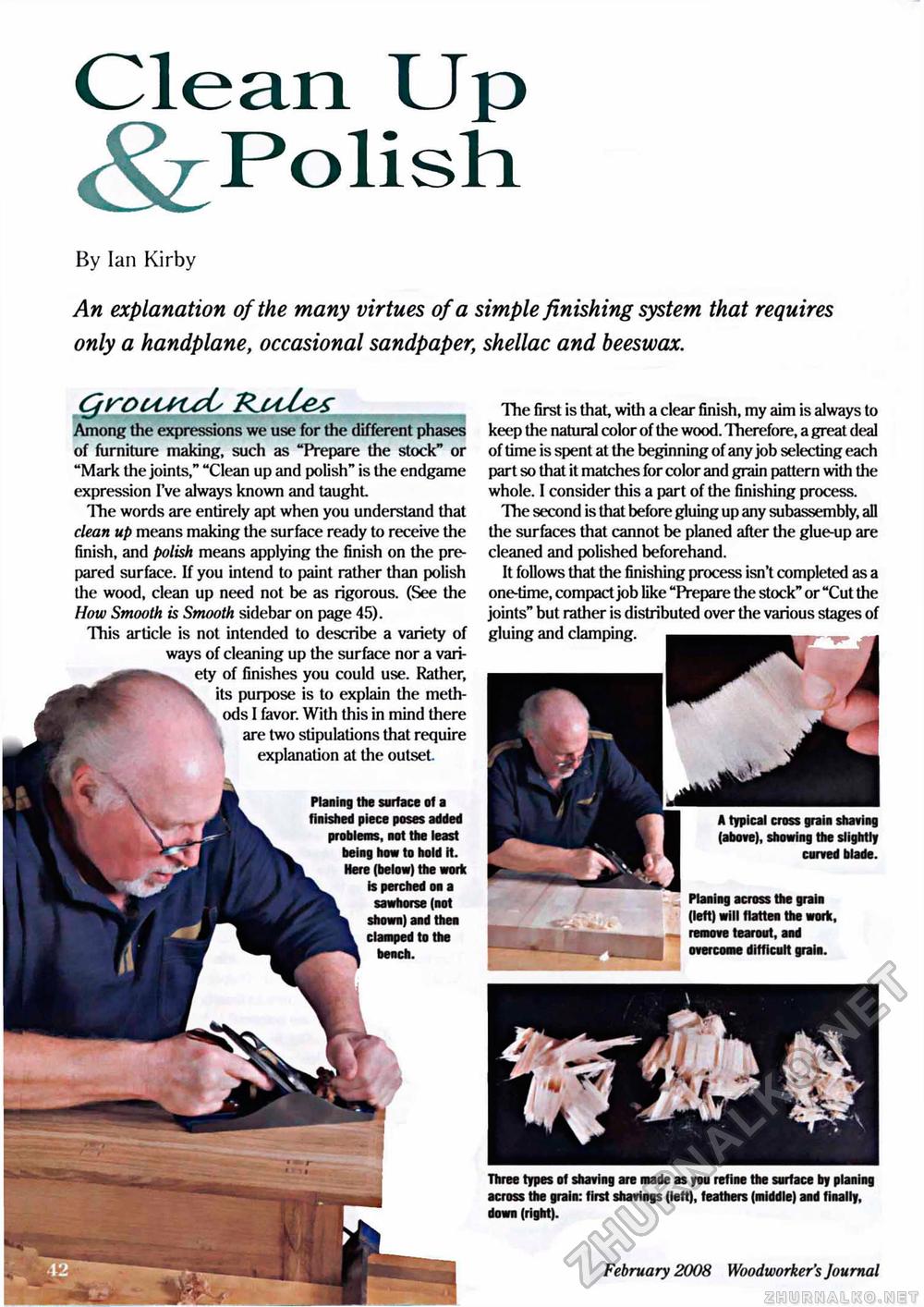

Clean Up By Ian Kirby An explanation of the many virtues of a simple finishing system that requires only a handplane, occasional sandpaper, shellac and beeswax. The first is that, with a clear finish, my aim is always to keep the natural color of the wood. Therefore, a great deal of time is spent at the beginning of any job selecting each part so that it matches for color and grain pattern with the whole. I consider this a part of the finishing process. The second is that before gluing up any subassembly, all the surfaces that cannot be planed after the glue-up are cleaned and polished beforehand. It follows that the finishing process isn't completed as a one-time, compact job like "Prepare the stock" or "Cut the joints" but rather is distributed over the various stages of gluing and clamping. - A typical cross grain shaving (above), showing the slightly curved blade. Planing across the grain (left) will flatten the wort, remove tearout, and overcome difficult grain. GrousttC ' " " * — ----n; Among the expressions we use for the different phases of furniture making, such as "Prepare the stock" or "Mark the joints," "Clean up and polish" is the endgame expression I've always known and taught. The words are entirely apt when you understand that clean up means making the surface ready to receive the finish, and polish means applying the finish on the prepared surface. If you intend to paint rather than polish the wood, clean up need not be as rigorous. (See the How Smooth is Smooth sidebar on page 45). This article is not intended to describe a variety of ways of cleaning up the surface nor a variety of finishes you could use. Rather, its purpose is to explain the methods I favor. With this in mind there are two stipulations that require explanation at the outset. Planing the surface of a finished piece poses added problems, not the least being how to hold It. Here (below) the work is perched on a sawhorse (not shown) and thea clamped to the bench. Three types of shaving are made as you refine the surface by planing across the grain: first shavings (left), feathers (middle) and finally, down (right). 23 February 2008 Woodworker's Journal |