Woodworker's Journal 2008-32-1, страница 27

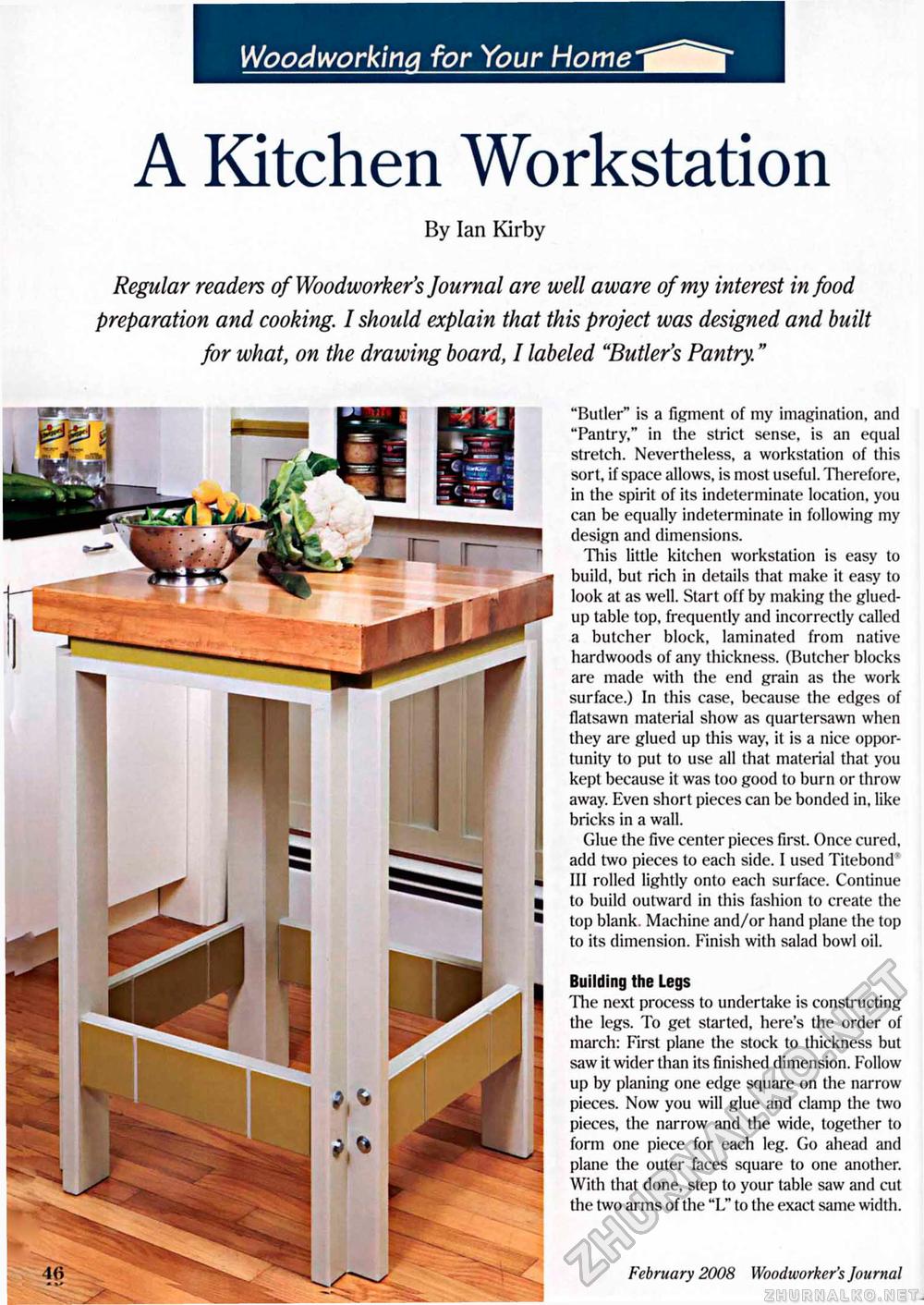

Woodworking for Your Home A Kitchen WorkstationBy Ian Kirby Regular readers of Woodworker's Journal are well aware of my interest in food preparation and cooking. I should explain that this project was designed and built for what, on the drawing board, I labeled "Butler's Pantry." H M "Butler" is a figment of my imagination, and "Pantry," in the strict sense, is an equal stretch. Nevertheless, a workstation of this sort, if space allows, is most useful. Therefore, in the spirit of its indeterminate location, you can be equally indeterminate in following my design and dimensions. This little kitchen workstation is easy to build, but rich in details that make it easy to look at as well. Start off by making the glued-up table top, frequently and incorrectly called a butcher block, laminated from native hardwoods of any thickness. (Butcher blocks are made with the end grain as the work surface.) In this case, because the edges of flatsawn material show as quartersawn when they are glued up this way, it is a nice opportunity to put to use all that material that you kept because it was too good to burn or throw away. Even short pieces can be bonded in, like bricks in a wall. Glue the five center pieces first. Once cured, add two pieces to each side. I used Titebond III rolled lightly onto each surface. Continue to build outward in this fashion to create the top blank. Machine and/or hand plane the top to its dimension. Finish with salad bowl oil. Building the Legs The next process to undertake is constructing the legs. To get started, here's the order of march: First plane the stock to thickness but saw it wider than its finished dimension. Follow up by planing one edge square on the narrow pieces. Now you will glue and clamp the two pieces, the narrow and the wide, together to form one piece for each leg. Go ahead and plane the outer faces square to one another. With that clone, step to your table saw and cut the two arms of the "L" to the exact same width. 27 February 2008 Woodworker's Journal |