Woodworker's Journal 2008-32-4, страница 34

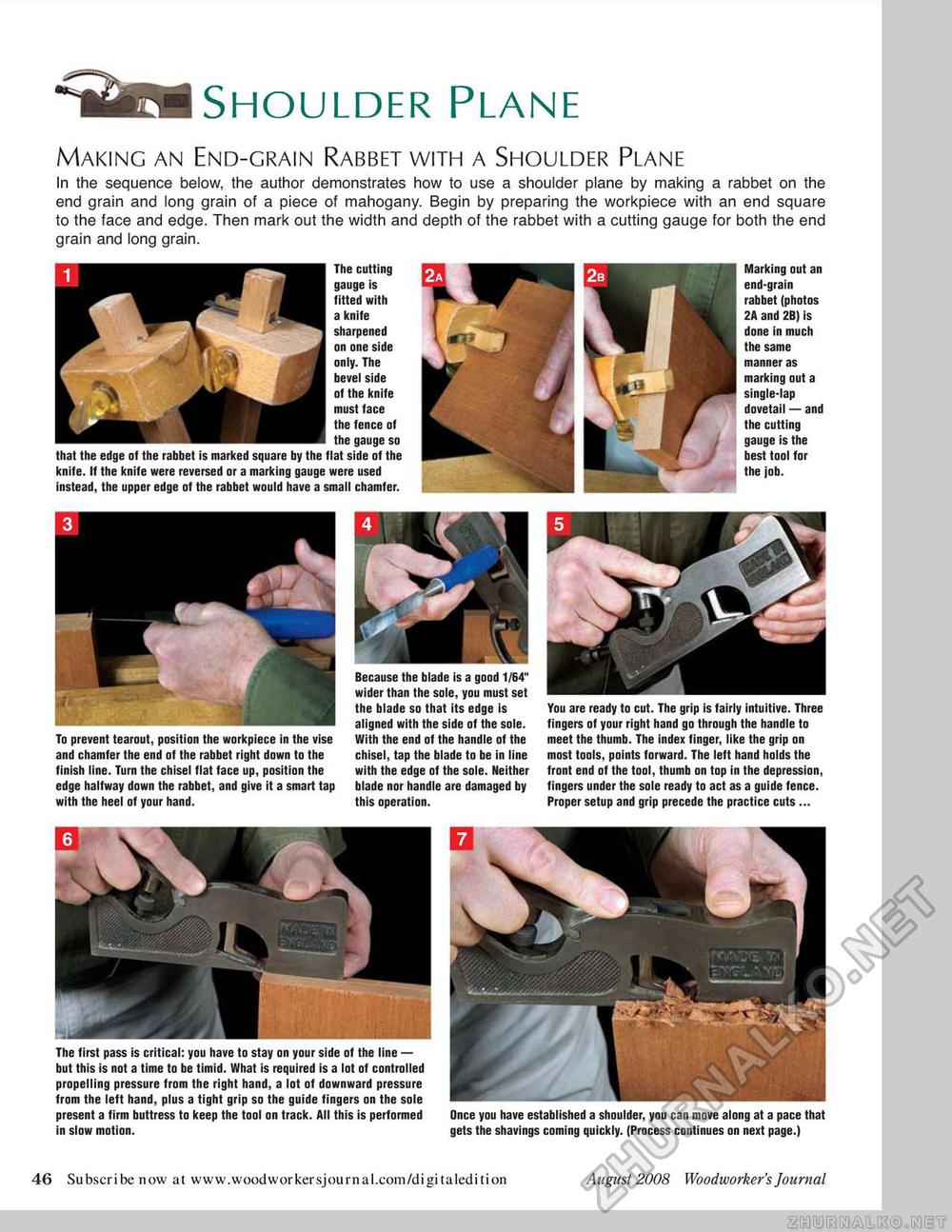

^■■shoulder planeMaking an End-grain Rabbet with a Shoulder Plane In the sequence below, the author demonstrates how to use a shoulder plane by making a rabbet on the end grain and long grain of a piece of mahogany. Begin by preparing the workpiece with an end square to the face and edge. Then mark out the width and depth of the rabbet with a cutting gauge for both the end grain and long grain. Marking out an end-grain rabbet (photos 2A and 2B) is done in much the same manner as marking out a single-lap dovetail — and the cutting gauge is the best tool for the job. To prevent tearout, position the workpiece in the vise and chamfer the end of the rabbet right down to the finish line. Turn the chisel flat face up, position the edge halfway down the rabbet, and give it a smart tap with the heel of your hand. Because the blade is a good 1/64" wider than the sole, you must set the blade so that its edge is aligned with the side of the sole. With the end of the handle of the chisel, tap the blade to be in line with the edge of the sole. Neither blade nor handle are damaged by this operation. You are ready to cut. The grip is fairly intuitive. Three fingers of your right hand go through the handle to meet the thumb. The index finger, like the grip on most tools, points forward. The left hand holds the front end of the tool, thumb on top in the depression, fingers under the sole ready to act as a guide fence. Proper setup and grip precede the practice cuts ... The first pass is critical: you have to stay on your side of the line — but this is not a time to be timid. What is required is a lot of controlled propelling pressure from the right hand, a lot of downward pressure from the left hand, plus a tight grip so the guide fingers on the sole present a firm buttress to keep the tool on track. All this is performed in slow motion. Once you have established a shoulder, you can move along at a pace that gets the shavings coming quickly. (Process continues on next page.) The cutting gauge is fitted with a knife sharpened on one side only. The bevel side of the knife must face the fence of - - - the gauge so that the edge of the rabbet is marked square by the flat side of the knife. If the knife were reversed or a marking gauge were used instead, the upper edge of the rabbet would have a small chamfer. 46 Subscribe now at www.woodworkersjournal.com/digitaledition August 2008 Woodworker's Journal |