Woodworker's Journal 2008-32-4, страница 33

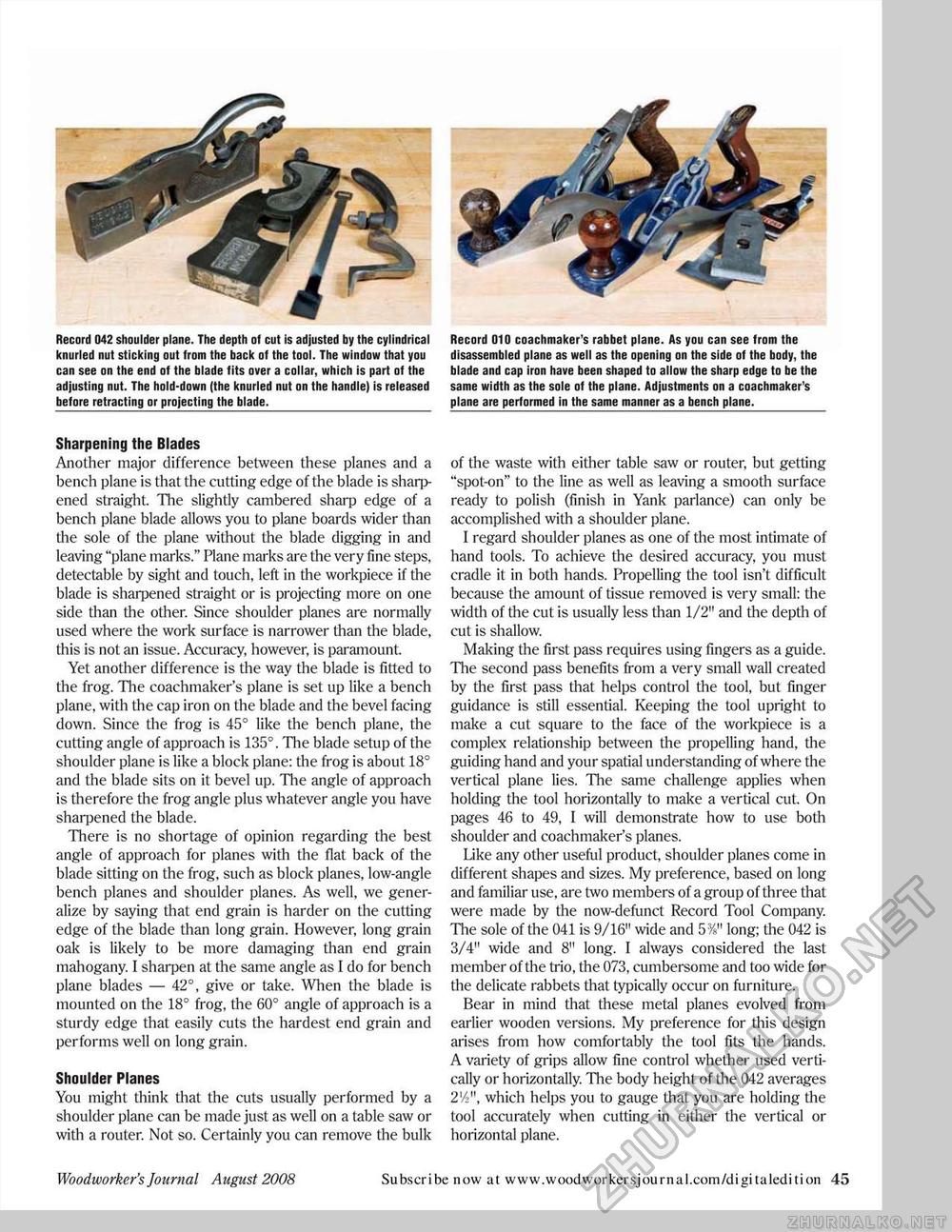

Record 042 shoulder plane. The depth of cut Is adjusted by the cylindrical knurled nut sticking out from the back of the tool. The window that you can see on the end of the blade fits over a collar, which is part of the adjusting nut. The hold-down (the knurled nut on the handle) is released before retracting or projecting the blade. Sharpening the Blades Another major difference between these planes and a bench plane is that the cutting edge of the blade is sharpened straight. The slightly cambered sharp edge of a bench plane blade allows you to plane boards wider than the sole of the plane without the blade digging in and leaving "plane marks." Plane marks are the very fine steps, detectable by sight and touch, left in the workpiece if the blade is sharpened straight or is projecting more on one side than the other. Since shoulder planes are normally used where the work surface is narrower than the blade, this is not an issue. Accuracy, however, is paramount. Yet another difference is the way the blade is fitted to the frog. The coachmaker's plane is set up like a bench plane, with the cap iron on the blade and the bevel facing down. Since the frog is 45° like the bench plane, the cutting angle of approach is 135°. The blade setup of the shoulder plane is like a block plane: the frog is about 18° and the blade sits on it bevel up. The angle of approach is therefore the frog angle plus whatever angle you have sharpened the blade. There is no shortage of opinion regarding the best angle of approach for planes with the flat back of the blade sitting on the frog, such as block planes, low-angle bench planes and shoulder planes. As well, we generalize by saying that end grain is harder on the cutting edge of the blade than long grain. However, long grain oak is likely to be more damaging than end grain mahogany. I sharpen at the same angle as I do for bench plane blades — 42°, give or take. When the blade is mounted on the 18° frog, the 60° angle of approach is a sturdy edge that easily cuts the hardest end grain and performs well on long grain. Shoulder Planes You might think that the cuts usually performed by a shoulder plane can be made just as well on a table saw or with a router. Not so. Certainly you can remove the bulk Record 010 coachmaker's rabbet plane. As you can see from the disassembled plane as well as the opening on the side of the body, the blade and cap iron have been shaped to allow the sharp edge to be the same width as the sole of the plane. Adjustments on a coachmaker's plane are performed in the same manner as a bench plane. of the waste with either table saw or router, but getting "spot-on" to the line as well as leaving a smooth surface ready to polish (finish in Yank parlance) can only be accomplished with a shoulder plane. I regard shoulder planes as one of the most intimate of hand tools. To achieve the desired accuracy, you must cradle it in both hands. Propelling the tool isn't difficult because the amount of tissue removed is very small: the width of the cut is usually less than 1/2" and the depth of cut is shallow. Making the first pass requires using fingers as a guide. The second pass benefits from a very small wall created by the first pass that helps control the tool, but finger guidance is still essential. Keeping the tool upright to make a cut square to the face of the workpiece is a complex relationship between the propelling hand, the guiding hand and your spatial understanding of where the vertical plane lies. The same challenge applies when holding the tool horizontally to make a vertical cut On pages 46 to 49, I will demonstrate how to use both shoulder and coachmaker's planes. Like any other useful product, shoulder planes come in different shapes and sizes. My preference, based on long and familiar use, are two members of a group of three that were made by the now-defunct Record Tool Company. The sole of the 041 is 9/16" wide and 5%" long; the 042 is 3/4" wide and 8" long. I always considered the last member of the trio, the 073, cumbersome and too wide for the delicate rabbets that typically occur on furniture. Bear in mind that these metal planes evolved from earlier wooden versions. My preference for this design arises from how comfortably the tool fits the hands. A variety of grips allow fine control whether used vertically or horizontally. The body height of the 042 averages 2'/>", which helps you to gauge that you are holding the tool accurately when cutting in either the vertical or horizontal plane. Woodworker's Journal August 2008 Subscr ibe now at www.woodworkersjournal.com/digitaledition 79 |