Woodworker's Journal 2008-32-5, страница 54

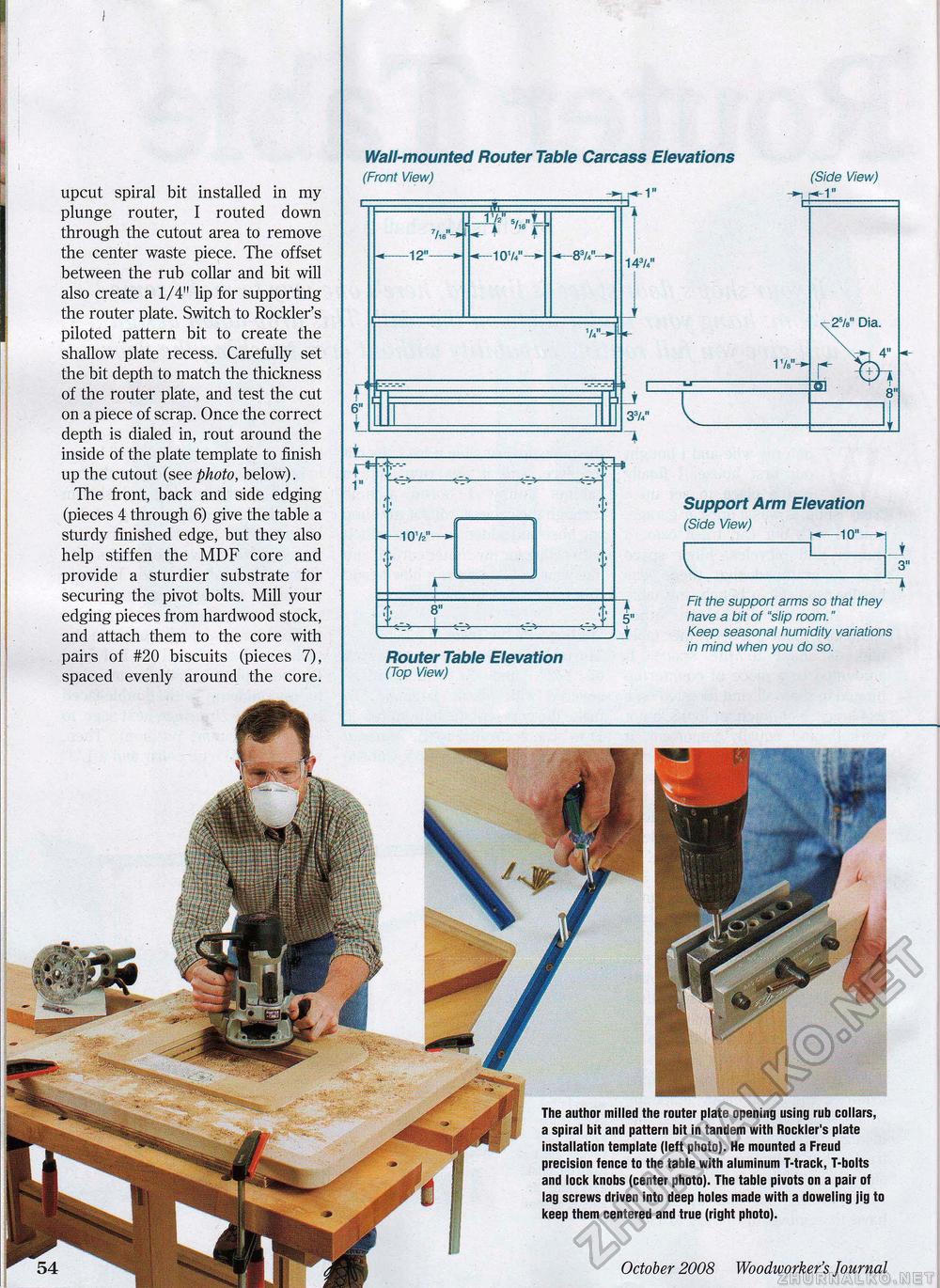

The author milled the router plate opening using rub collars, a spiral bit and pattern bit in tandem with Rockler's plate installation template (left photo). He mounted a Freud precision fence to the table with aluminum T-track, T-bolts and lock knobs (center photo). The table pivots on a pair of lag screws driven into deep holes made with a doweling jig to keep them centered and true (right photo). 54 October 2008 Woodworker's Journal upcut spiral bit installed in my plunge router, I routed down through the cutout area to remove the center waste piece. The offset between the rub collar and bit will also create a 1/4" lip for supporting the router plate. Switch to Rockler's piloted pattern bit to create the shallow plate recess. Carefully set the bit depth to match the thickness of the router plate, and test the cut on a piece of scrap. Once the correct depth is dialed in, rout around the inside of the plate template to finish up the cutout (see photo, below). The front, back and side edging (pieces 4 through 6) give the table a sturdy finished edge, but they also help stiffen the MDF core and provide a sturdier substrate for securing the pivot bolts. Mill your edging pieces from hardwood stock, and attach them to the core with pairs of #20 biscuits (pieces 7), spaced evenly around the core. -2%" Dia. Wall-mounted Router Table Carcass Elevations (Front View) (Side View) -»-, p<-1"_ Support Arm Elevation (Side View) Router Table Elevation (Top View) ; > Fit the support arms so that they have a bit of "slip room." Keep seasonal humidity variations in mind when you do so. |