Woodworker's Journal 2008-32-6, страница 48

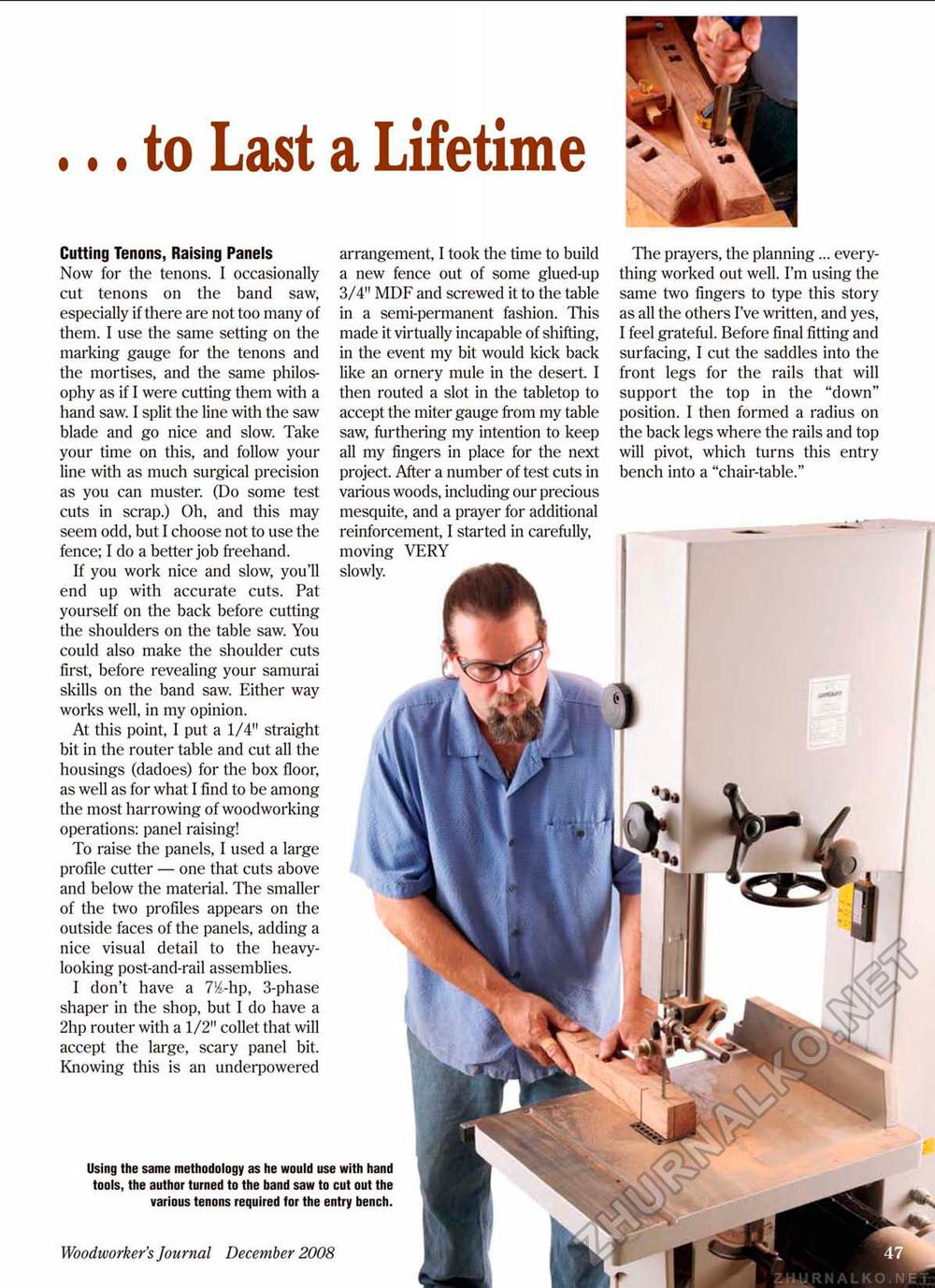

... to Last a Lifetime Cutting Tenons, Raising Panels Now for the tenons. I occasionally cut tenons on the band saw, especially if there are not too many of them, I use the same setting on the marking gauge for the tenons and the mortises, and the same philosophy as if I were cutting them with a hand saw. I split the line with the saw blade and go nice and slow. Take your time 011 this, and follow your line with as much surgical precision as you can muster. (Do some test cuts in scrap.) Oh, and this may seem odd. but I choose not to use the fence; 1 do a belter job freehand. If you work nice and slow, you'll end up with accurate cuts. Pat yourself on the back before cutting the shoulders on the table saw. You could also make the shoulder cuts first, before revealing your samurai skills on the band saw. Either way works well, in my opinion. At this point, I put a 1/4" straight bit in the router table and cut all the housings (dadoes) for the box floor, as well as for what I find to be among the most harrowing of woodworking operations: panel raising! To raise the panels, I used a large profile cutler — one that cuts above and below the material. The smaller of the two profiles appears on the outside faces of the panels, adding a nice visual detail to the heavy-looking post-and-rail assemblies. I don't have a 7!4-hp, 3-phase shaper in the shop, but I do have a 2hp router with a 1/2" collet that will accept the large, scary panel bit. Knowing this is an underpowered arrangement, I took the time to build a new fence out of some glued-up 3/4" MDF and screwed it to the table in a semi-permanent fashion. This made it virtually incapable of shifting, in the event my bit would kick back like an ornery mule in the desert. I then routed a slot in the tabletop to accept the miter gauge from my table saw, furthering my intention to keep ail my fingers in place for the next project. After a number of test cuts in various woods, including our precious mesquite, and a prayer for additional reinforcement, I started in carefully, moving VERY slowly. The prayers, the planning ... everything worked out well. I'm using the same two fingers to type this story as all the others I've written, and yes, I feel grateful. Before final fitting and surfacing, I cut the saddles into the front legs for the rails that will support the top in the "down" position. 1 then formed a radius on the back legs where the rails and top will pivot, which turns this entry bench into a "chair-table." Using the same methodology as he would use with hand tools, the author turned to the band saw to cot out the various tenons required for the entry bench. Woodworker's Journal December 2008 48 |