Woodworker's Journal 2010-34-1, страница 37

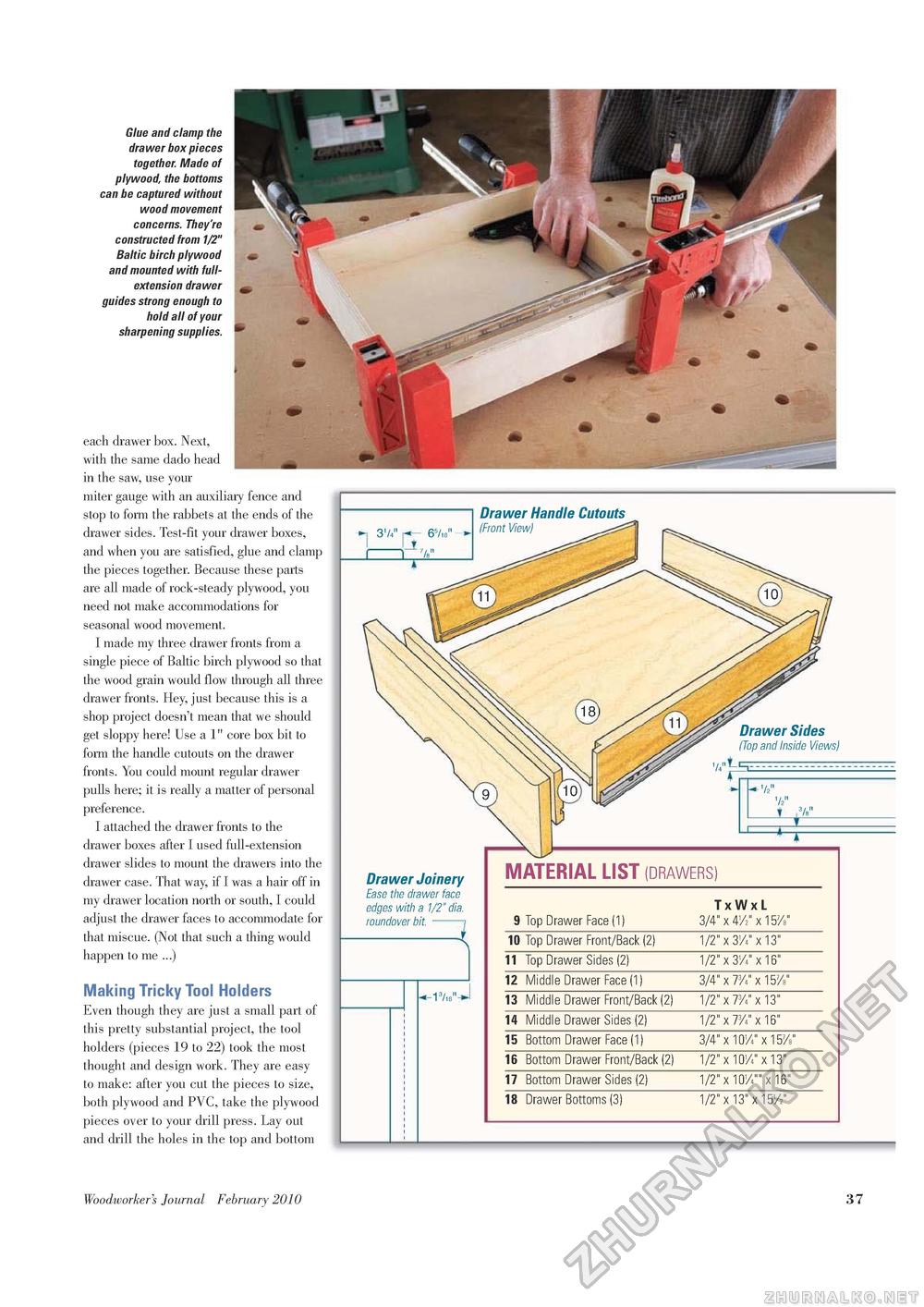

Glue and clamp the drawer box pieces together. Made of plywood, the bottoms can be captured without wood movement concerns. They're constructed from 1/2" Baltic birch plywood and mounted with full-extension drawer guides strong enough to hold all of your sharpening supplies. each drawer box. Next, with the same dado head in the saw, use your miter gauge with an auxiliary fence and stop to form the rabbets at the ends of the drawer sides. Test-fit your drawer boxes, and when you are satisfied, glue and clamp the pieces together. Because these parts are all made of rock-steady plywood, you need not make accommodations for seasonal wood movement. I made my three drawer fronts from a single piece of Baltic birch plywood so that the wood grain would flow through all three drawer fronts. Hey, just because this is a shop project doesn't mean that we should get sloppy here! Use a 1" core box bit to form the handle cutouts on the drawer fronts. You could mount regular drawer pulls here; it is really a matter of personal preference. I attached the drawer fronts to the drawer boxes after I used full-extension drawer slides to mount the drawers into the drawer case. That way, if I was a hair off in my drawer location north or south, I could adjust the drawer faces to accommodate for that miscue. (Not that such a thing would happen to me ...) Making Tricky Tool Holders Even though they are just a small part of this pretty substantial project, the tool holders (pieces 19 to 22) took the most thought and design work. They are easy to make: after you cut the pieces to size, both plywood and PVC, take the plywood pieces over to your drill press. Lay out and drill the holes in the top and bottom Drawer Handle Cutouts (Front View) Drawer Sides (Top and Inside Views) 'A?" f 3'- Drawer Joinery Ease the drawer face edges with a 1/2" dia. roundover bit I MATERIAL LIST (drawers)

17ie" Woodworker's Journal Ferbruary 2010 37 |

||||||||||||||||||||||||||||||