Woodworker's Journal 2010-34-2, страница 27

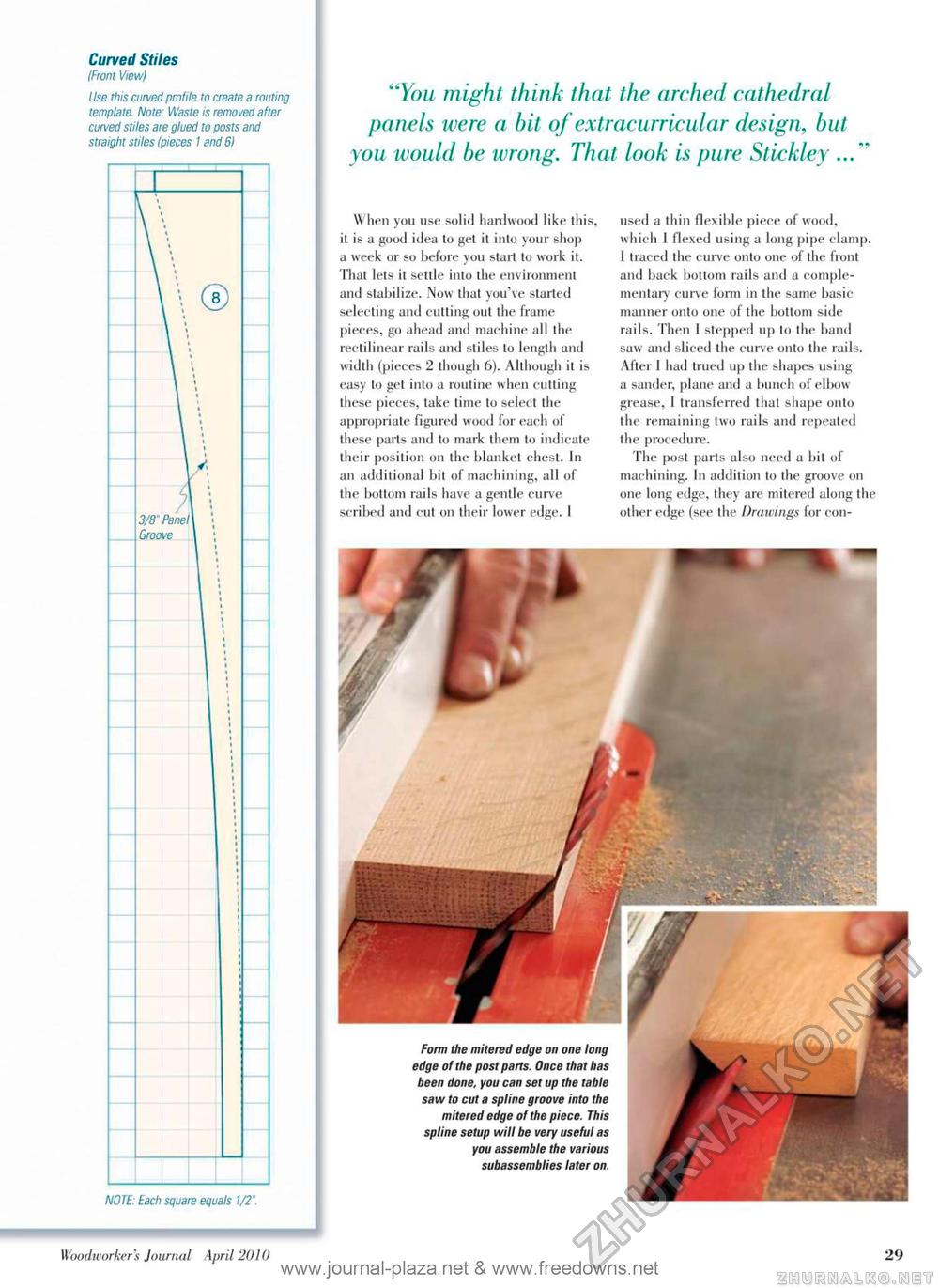

Curved Stiles IFront View) Use this curved profile to create a routing template. Note: Waste is removed after curved stiles are glued to posts and straight stiles (pieces 1 and 6) "You might think that the arched cathedral panels were a bit of extracurricular design, but you would be wrong. That look is pure Stickley \\ hen you use solid hardwood like this, it is a good idea to get it into your shop a week or so before you start to work it. That lets it settle into the environment and stabilize. Now that you've started selecting and cutting out the frame pieces, go ahead and machine all the rectilinear rails and stiles to length and width (pieces 2 though 6). Although it is easy to gel into a routine when cutting these pieces, take time to select the appropriate figured wood for each of these parts and to mark them to indicate their position on the blanket chest. In an additional bit of machining, all of the bottom rails have a gentle curve scribed and cut on their lower edge. I used a thin flexible piece of wood, which I flexed using a long pipe clamp. 1 traced the curve onto one of the front and back bottom rails and a complementary curve form in the same basic manner onto one of the bottom side rails. Then I stepped up to the band saw and sliced the curve onto the rails. After 1 had trued up the shapes using a sander, plane and a bunch of elbow grease, 1 transferred that shape onto the remaining two rails and repeated the procedure. The post parts also need a bit of machining. In addition to the groove on one long edge, they are mitered along the other edge (see the Drawings for con- NOTE: Each square equals 1/2". Form the mitered edge on one long edge of the post parts. Once that has been done, you can set up the table saw to cut a spline groove into the mitered edge of the piece. This spline setup will be very useful as you assemble the various subassemblies later on. Woodworker's Journal April 2010 www.journal-plaza.net & www.freedowns.net it |