Woodworker's Journal 2011-35-1, страница 44

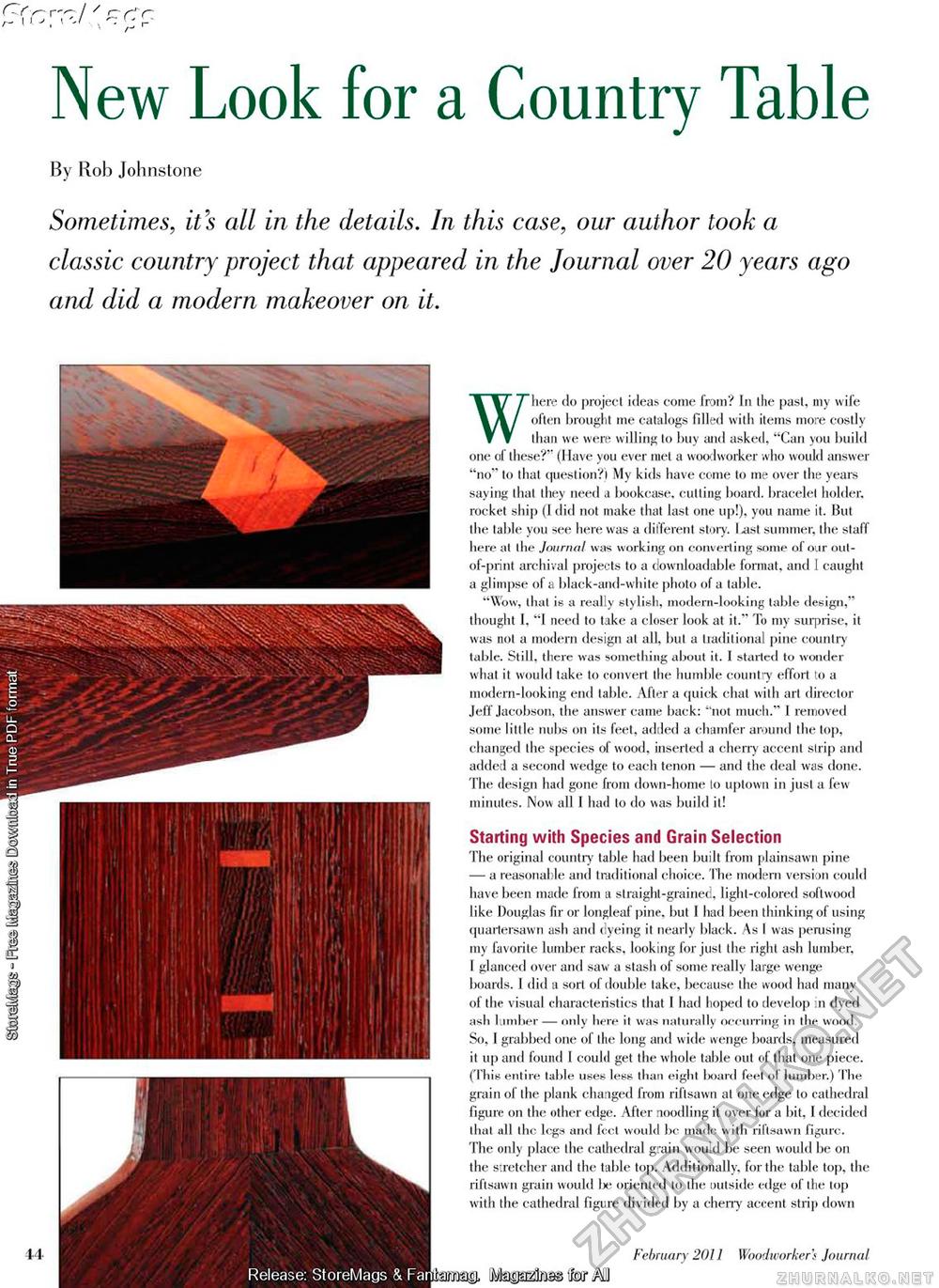

y— / / r* c New Look for a Country TableBy Rob Johnstone Sometimes, its all in the details. In this case, our author took a classic country project that appeared in the Journal over 20 years ago and did a modern makeover on it. There do project ideas come from? In the past, my wife % \ / often brought me catalogs filled with items more costly T ▼ than we were willing to buy and asked, "Can you build one of these?" (1 lave you ever met a woodworker who would answer "no" to that question?) My kids have come to me over the years saying that they need a bookcase, cutting board, bracelet holder, rocket ship (I did not make that last one up!), you name it. But the table you see here was a different story. Last summer, the staff here at the Journal was working on converting some of our out-of-print archival projects to a downloadable format, and 1 caught a glimpse of a black-and-white photo of a table. "Wow, that is a really stylish, modern-looking table design," thought I, "I need to take a closer look at it." To my surprise, it was not a modern design at all, but a traditional pine country table. Still, there was something about it. I started to wonder what it would take to convert the humble country effort to a modern-looking end table. After a quick chat with art director Jeff Jacobson, the answer came back: "not much." I removed some little nubs on its feet, added a chamfer around the top, changed the species of wood, inserted a cherry accent strip and added a second wedge to each tenon — and the deal was done. The design had gone from down-home to uptown in just a few minutes. Now all I had to do was build it! Starting with Species and Grain Selection The original country table had been built from plainsawn pine — a reasonable and traditional choice. The modern version could have been made from a straight-grained, light-colored softwood like Douglas fir or longleaf pine, but I had been thinking of using quartersawn ash and dyeing it nearly black. As I was perusing my favorite lumber racks, looking for just the right ash lumber, 1 glanced over and saw a stash of some really large wenge boards. 1 did a sort of double take, because the wood had many of the visual characteristics that 1 had hoped to develop in dyed ash lumber — only here it was naturally occurring in the wood. So, 1 grabbed one of the long and wide wenge boards, measured it up and found 1 could get the whole table out of that one piece. (This entire table uses less than eight board feet of lumber.) The grain of the plank changed from riftsawn at one edge to cathedral figure on the other edge. After noodling it over for a bit, 1 decided that all the legs and feet would be made with riftsawn figure. The only place the cathedral grain would be seen would be on the stretcher and the table top. Additionally, for the table top, the riftsawn grain would be oriented to the outside edge of the top with the cathedral figure divided by a cherry accent strip down February 2011 Woodworkers Journal |